A.O. Smith 400A User Manual

Page 11

WARNING

NEVER OPERATE THE HEATER UNLESS IT IS VENTED TO THE

OUTDOORS AND HAS ADEQUATE AIR SUPPLY TO AVOID RISKS OF

IMPROPER OPERATION, FIRE, EXPLOSION OR ASPHYXIATION.

VENT PIPE TERMINATION

NOTE: Before installing venting, determine place of vent pipe

termination. See Figure 5 and 6 before proceeding.

CAUTION

DO NOT TERMINATE THE VENTING WHERE NOISE FROM

THE EXHAUST OR INTAKE WILL BE OBJECTIONABLE. THIS

INCLUDES LOCATIONS CLOSE TO OR ACROSS FROM

WINDOWS AND DOORS. AVOID ANCHORING THE VENT AND

INTAKE PIPES DIRECTLY TO FRAMED WALLS, FLOORS OR

CEILINGS UNLESS RUBBER ISOLATION PIPE HANGERS

ARE USED. THIS PREVENTS ANY VIBRATIONS FROM BEING

TRANSMITTED INTO THE LIVING SPACES.

IMPORTANT

The vent system must terminate so that proper clearances are

maintained as cited in local codes or the current editions of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 or the Natural Gas

and Propane Installation Code, CAN/CSA-B149.1.

Do not terminate the exhaust vent terminal over public area where

condensate or vapor can cause nuisance or hazard.

Plan the vent system layout so that proper clearances are maintained

from plumbing and wiring.

Vent pipes serving power vented appliances are classified by building

codes as "vent connectors". Required clearances from combustible

materials must be provided in accordance with information in this

manual under LOCATION OF HEATER and CLEARANCES, and

with National Fuel Gas Code and local Codes.

IMPORTANT

Plan the layout of the vent system backwards from the vent

termination to the appliance.

WARNING

USE ONLY THE VENT TERMINALS SUPPLIED WITH THIS UNIT.

TERMINATION OF A VENT SYSTEM WITH A DEVICE OTHER THAN

THE SUPPLIED VENT TERMINATIONS WILL AFFECT SYSTEM

PERFORMANCE AND RESULT IN A SAFETY HAZARD.

DIRECT VENTING

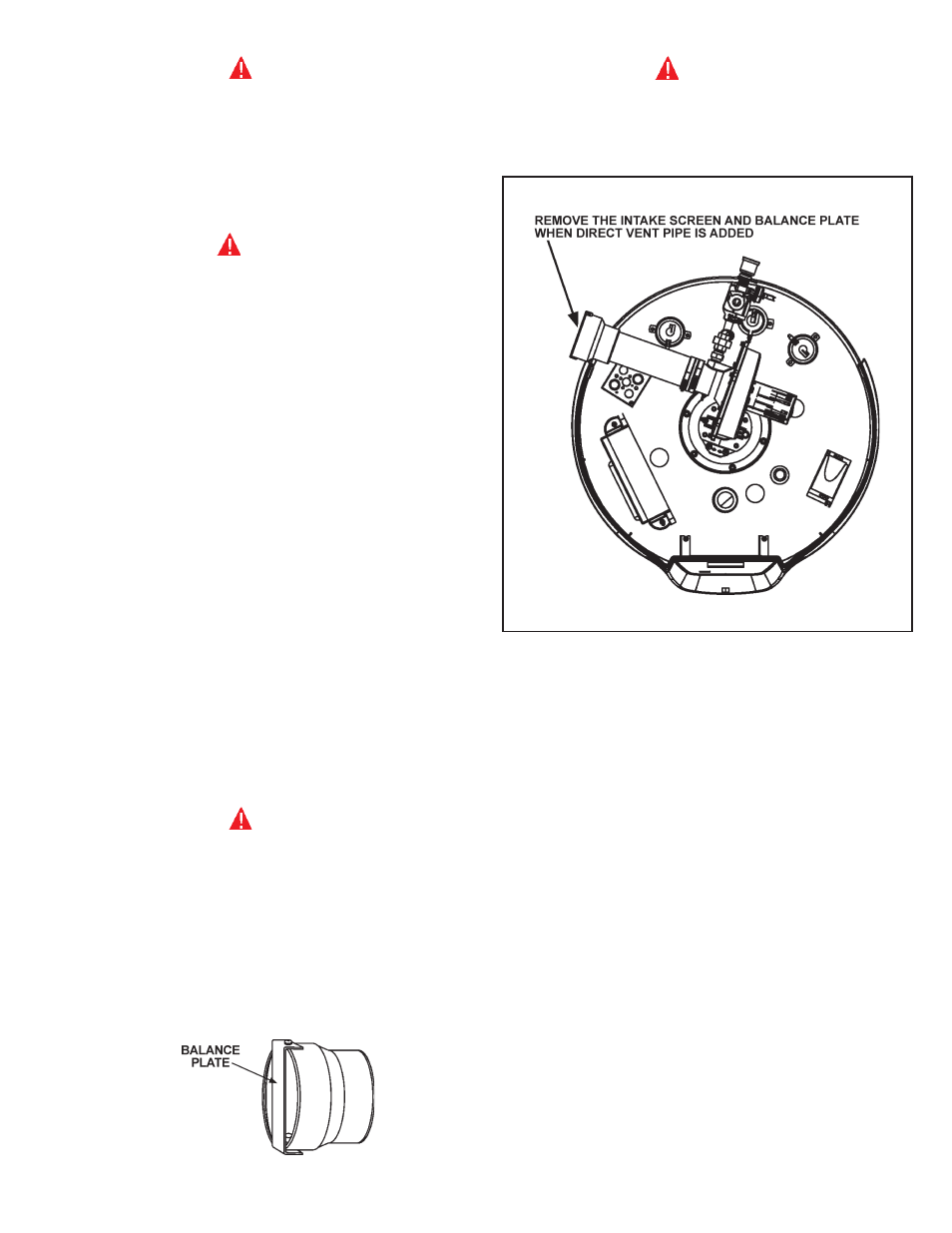

The air intake provided on the unit contains an intake guard, see

Figure 7.

3"x 4" PVC REDUCER WITH INTAKE SCREEN

FIGURE 7.

WARNING

WHEN THE UNIT IS TO BE SETUP AS A DIRECT VENT,

THE INTAKE GUARD AND THE BALANCE PLATE MUST BE

REMOVED. THE INLET VENT PIPE MAY THEN BE GLUED TO

THE AIR INTAKE (see Figure 8) PROVIDED ON THE UNIT.

FIGURE 8.

DIRECT VENT TERMINAL INSTALLATION

IMPORTANT

4" VENT AND INTAKE TERMINALS ARE PROVIDED FOR

NEW INSTALLATIONS. FOR REPLACEMENT OF PREVIOUS

BTH 300 AND 400 WITH 3" TERMINALS, THE 4" TERMINALS

ARE RECOMMENDED, BUT THE EXISTING 3" VENT/INTAKE

TERMINALS ARE PERMITTED.

NOTE: TO PREVENT EXHAUSTING PRODUCTS FROM

CIRCULATING TO THE AIR INTAKE IN WINDY/COLD AREAS,

THE MAXIMUM PRACTICAL DISTANCE BETWEEN THESE TWO

TERMINALS IS RECOMMENDED.

IMPORTANT

WHEN LOCATING THE TERMINALS ON A SIDEWALL, THE

FOLLOWING SPECIFICATIONS PERTAINING TO TERMINAL

LOCATION MUST BE FOLLOWED.

1. The intake vent terminal and the exhaust vent terminal must

terminate on the same exterior wall and must be located at

a minimum of 24" (61cm) from the vertical centerline of the

exhaust vent terminal (see Figure 9). In colder climates

increasing the 24" (61cm) minimum to 48" (122cm) will

reduce possibility of frost over from side winds blowing

exhaust vapors to the air intake of the direct the vent and is

recommended for Canada.