Accessories, Ce declaration, Warranty – Karcher HKF 200 ET User Manual

Page 34

34

English

*

Possible for max. 4,000 l/h flow of cleaning

liquid. With higher flow volumes of cleaning

liquids, please consult Kärcher.

1)

The hoses for solvent operation must be

electrostatically conductive!

We hereby declare that the machine de-

scribed below complies with the relevant

basic safety and health requirements of the

EU Directives, both in its basic design and

construction as well as in the version put

into circulation by us. This declaration shall

cease to be valid if the machine is modified

without our prior approval.

5.957-454

5.957-735

The undersigned act on behalf and under

the power of attorney of the company man-

agement.

Alfred Kärcher GmbH Co. KG

Alfred-Kärcher-Str. 28 - 40

D - 71364 Winnenden

Phone: +49 7195 14-0

Fax: +49 7195 14-2212

The warranty terms published by our com-

petent sales company are applicable in

each country. We will repair potential fail-

ures of the appliance within the warranty

period free of charge, provided that such

failure is caused by faulty material or de-

fects in fabrication.

In the event of a warranty claim please con-

tact your dealer or the nearest authorized

Customer Service centre. Please submit

the appliance, including all accessories,

and the proof of purchase.

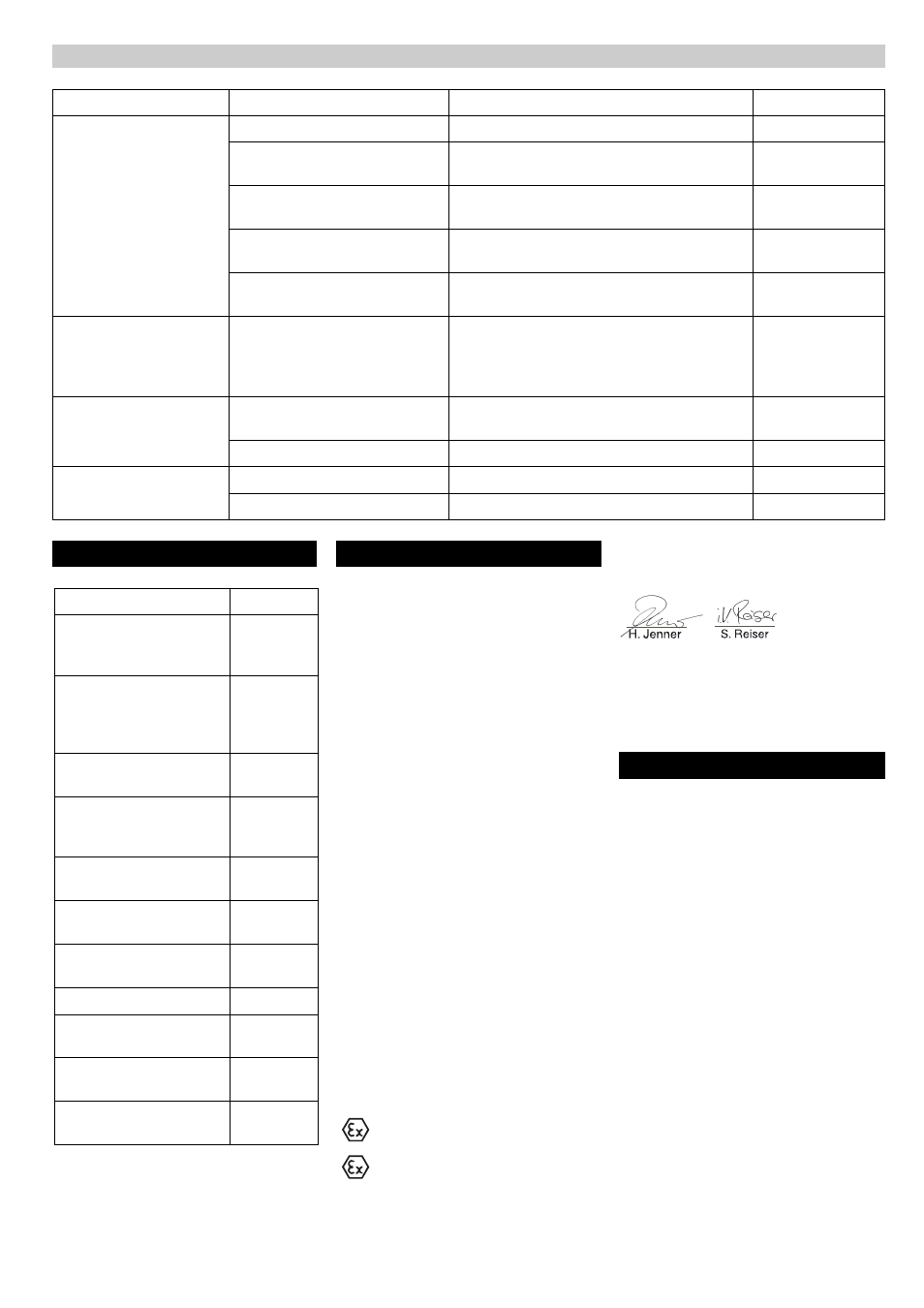

Troubleshooting

Fault

Possible cause

Remedy

of whom

Motor does not turn.

There is no voltage at the motor.

Check fuses and cables.

Electricians

Protective motor switch was trig-

gered.

Fix cause for overload, reset motor protection

switch.

Electricians

Error current protective switch

was triggered.

Remove cause and reset error current protec-

tive switch.

Electricians

No compressed air present or

pressure too low.

Check compressed air supply.

Operator

Compressed air supply line

kinked.

Check compressed air hoses.

Operator

Motor does not turn, clean-

ing head does not turn

Mechanical defect on:

– Coupling parts

– Drive shaft

– Gears

Check parts and replace defective parts.

Customer Service

Cleaning head turns too

abruptly

Worn drive discs cause increased

bevel play.

Replace drive discs.

Customer Service

Destroyed gears on bevel wheels. Replace bevel wheels.

Customer Service

Uneven cleaning jet

Spray nozzles clogged.

Clean spray nozzles.

Operator

Spray nozzles damaged.

Replace spray nozzles.

Operator

Accessories

Description

Order No.

Maintenance unit for com-

pressed air (only for com-

pressed air drive)

6.610-020

Compressed air filter with

automatic condensate

drain (only for compressed

air drive)

6.414-154

Bow (stainless steel) for

HKF 200 P, HKF 200 PT

4.034-016

Bow (stainless steel) for

HKF 200 E, HKF 200 ET,

HKF 200 C, HKF 200 C2

4.034-126

Horizontal rack (stainless

steel), diameter 560 mm

4.210-022

High pressure hose

NW 13 - 1.5 m

*1)

6.389-126

High pressure hose

NW 13 -10 m

*1)

4.440-173

Kupplung NW 13

*

4.403-002

90° screwed coupling

NW 13

*

4.408-023

Compressed air hose

(sold by the meter)

6.388-192

Exhaust air silencer with

oil separator

on request

CE declaration

Product:

Internal cleaner

Type:

HKF 200

Relevant EU Directives

98/37/EC (to 28.12.2009)

2006/42/EC (from 29.12.2009)

94/9/EC

Applied harmonized standards

EN ISO 12100–1

EN ISO 12100–2

EN 1127-1: 1997

EN 13463-1: 2002

EN 13463-5: 2003

HKF 200 E, HKF 200 ET, HKF 200 C, HKF

200 C2:

EN 60204–1

Applied national standards

-

ID no. of notified body

0123

TÜV SÜD

Ridlerstr. 65

80339 München

Test report no.

Ex5 0307 10088 097

Marking

II 1/2 G c T4

II 1/3 D c 120°C

Warranty

CEO

Head of Approbation