Karcher HKF 200 ET User Manual

Page 30

30

English

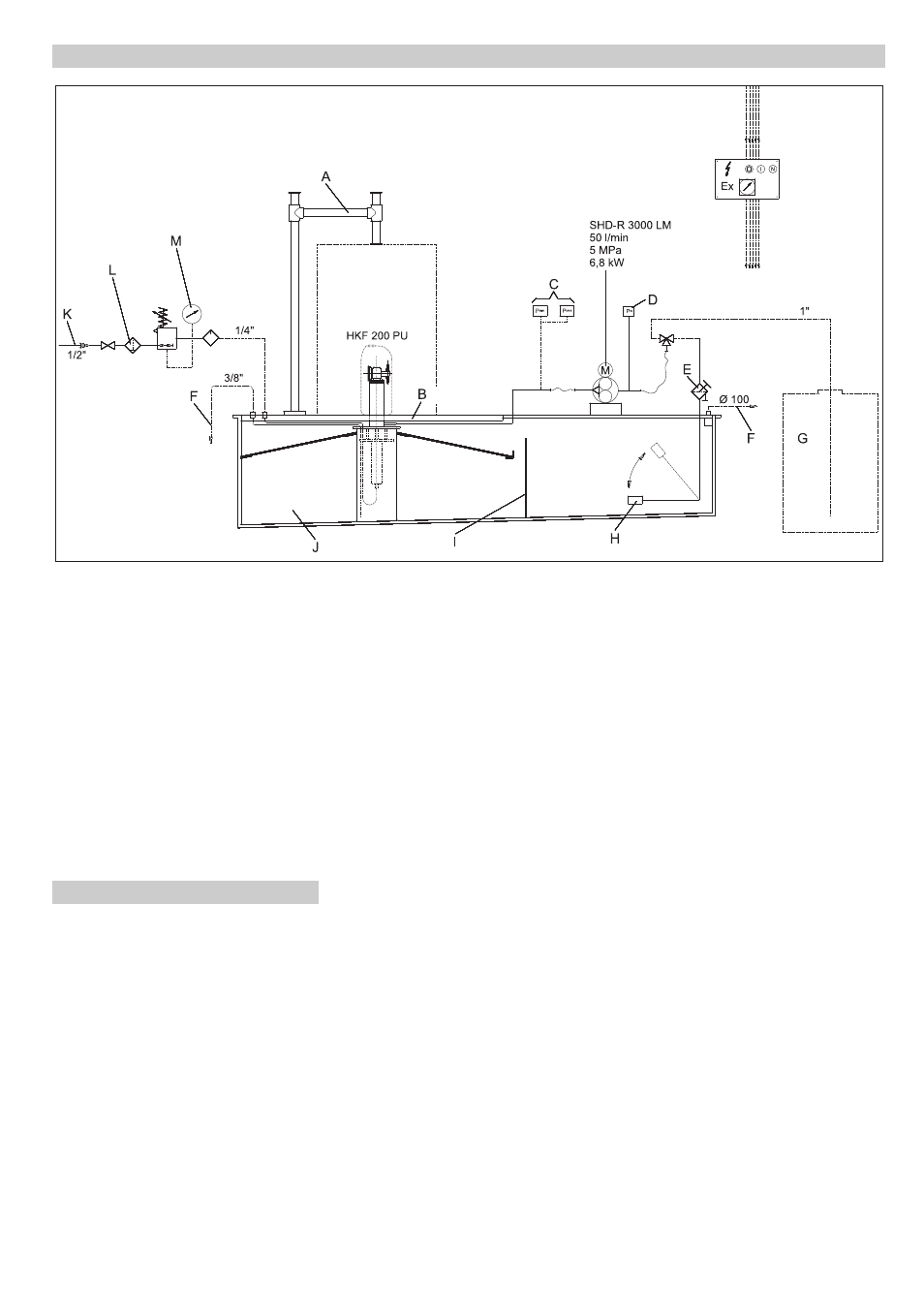

A Support unit (support unit with seat con-

tact button = option)

B Grid

C Option

D Filter monitoring

E Wire split filter

F Exhaust air

G Clear flushing liquid supply, by custom-

er

H Suction filter, swivellable

I

Sieve

J Compact circuit basin

Length x width x height = 2700 mm x

1500 mm x 650 mm

K Compressed air 0.4-0.7 MPa -300 l/min

L Compressed air filter

M Maintenance unit

ƽ

Danger

– The explosion protection must be taken

into consideration when operating with

solvents as well as in EX zones!

– Maximum pressure with solvent opera-

tion: 5 MPa

– Maximum flow volume with solvent op-

eration: 50 l/min

ṇ

Warning

When operating with solvents, the sealing

materials are less resistent, therefore they

must be flushed immediately after use! En-

quire with Kärcher!

1 Hydrocarbons

Example: Petroleum

2 Aromates (solvents)

Example: Benzene, toluene

3 Ketones

Example: MEK (Methyle Ethyle Ke-

tones), Acetone

4 Ester

Example: Butylacetate, Methylacetate

5 Glycoles

Example: Butyl glycole

6 Mixed solvents

Example: Butyl acetate 85, Isobutyl ac-

etate 85 (85 = 85% Butyl acetate + 15%

n-Butanol)

7 Regenerates, distillates from different

solvents, which have already been used

for cleaning purposes or similar applica-

tions.

1 Water with alkaline cleaning agents

(max. 0-2%)

Example: Kärcher cleaning agents

RM31

2 Caustic soda max. 10%, without hy-

pochlorite particles

3 Potassium hydroxide max. 10%, without

hypochlorite particles

ṇ

Warning

– The material will be worn off faster when

using hydrochloric or sulfuric acids;

therefore it must be rinsed/neutralised

immediately!

– Contaminated acids will decrease the

resilience!

– Enquire with Kärcher if needed!

1 Water with acid cleaning agents (max.

0-1%)

Example: Kärcher cleaning agents

RM25

2 Acids (max. temperature +20 °C)

Nitric acid max. 10%.

Acetic acid max. 10%.

Formic acid max. 10%.

Phosphoric acid max. 10%.

Citric acid max. 10%.

Sulfuric acid max. 0.5%.

Hydrochloric acid max. 0.5%.

1 Water

2 Fully desalted water

If other cleaning liquids are used, their resil-

ience must be checked by means of the

materials list! These cleaning liquids can

only be used after being released by Kärch-

er!

Installation example HKF 200 PU

Cleaning liquids

solvents

Brines

Acids

Water

Other cleaning liquids