A.J. Antunes & Co SML 8221210034 User Manual

Sml installation information, Sml switches, Dimensions

1-630-784-1000 Fax: 630-784-1651

Page 1 of 4

P/N 1011084 06/10

1-800-253-2991

A. J. ANTUNES & CO. www.ajantunes.com 180 Kehoe Blvd., Carol Stream, Illinois 60188

SML Switches

You are installing one of the finest switches of its type on

the market. You will find this switch has many superior

features that ensure dependable, accurate, long life oper-

ation. This switch is highly sensitive and fully approved. It

is UL and CSA listed and has FM approval (optional).

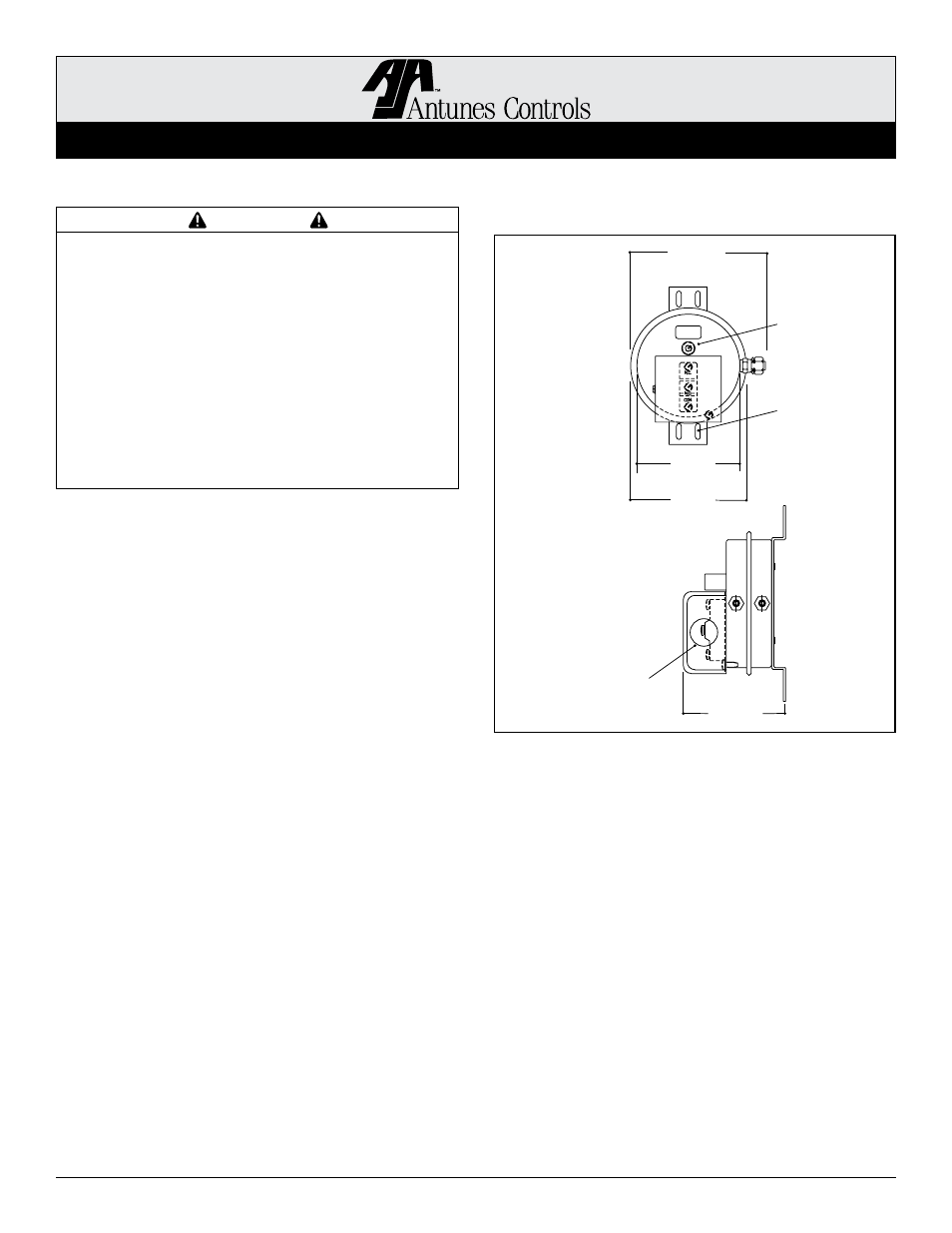

Dimensions

IMPORTANT

Please read these instructions carefully to assure

correct installation. This equipment must be

installed only by a licensed electrician who is

experienced with combustion safeguard control

systems and understands the functions of inter-

locking switches, such as gas pressure switches.

Prior to being put into operation in conjunction

with the combustion safeguard systems, all

switches should be tested for proper range setting

and proper wiring. Check piping connections and

switch house for leaks with a soap bubble test. All

exhaust fans and blowers should be inspected and

checked for proper rotation prior to starting up.

SML Installation Information

Specifications

Electrical Ratings: 10A @ 125 VAC, 8A @ 250 VAC, 7A

@ 277 VAC, 1/8 HP @ 125 VAC, 1/4 HP @250 VAC

Pilot Duty, 125 VA @ 125/277 VAC

Max. Surge Pressure: 20” W.C.

Max. Ambient Operating Temperature: 170°F (77°C)

Min. Ambient Operating Temperature: -40°F (-40°C)

Shipping Weight: 1 lbs. (.45 kg)

Optional Fittings:

1/4” Barb

1/4” Tube

1/4” Compression

Option: Neon Light Indicator

NOTE: Location of fittings and types of fittings may vary

from unit to unit.

Range Adjustment

All settings are made with the diaphragm in a vertical

position. The switch is shipped with the adjustment at

minimum .05” W. C.

To adjust, turn adjusting screw with screwdriver. To

increase pressure setting, turn adjustment screw in a

clockwise direction. To decrease pressure setting, turn

adjusting screw up in a counterclockwise direction.

If adjusting screw is removed, apply a non-hardening

pipe compound to the threads before replacing. Check for

leaks with a soap bubble test using maximum 20” W.C.

Installation

Models may be mounted in the horizontal or vertical posi-

tion. All switches are tested at the factory in a vertical

position. Mounting diaphragm in vertical position is the

preferred method.

If mounting in horizontal position, the micro switch must

be on top. When mounted in this position, the minimum

sensitivity may be higher than that specified.

Standard mounting

bracket is shown.

For other mounting

arrangements,

contact factory.

5 5/32”

(131 mm)

Standpipe with

adjusting

screw

Mounting holes

for #8 screws

1/2” Conduit

Knockout

4 9/16”

(116 mm)

4 1/16”

(103 mm)

3 5/16”

(135 mm)

NOTE: Dimensions

are for reference only.