Blade removal, Blade carrier removal, Blade carrier inspection – Alamo RX96 User Manual

Page 154: Maintenance

MAINTENANCE

RX96 03/09

Maintenance Section 5-10

© 2009 Alamo Group Inc.

MAINTENANCE

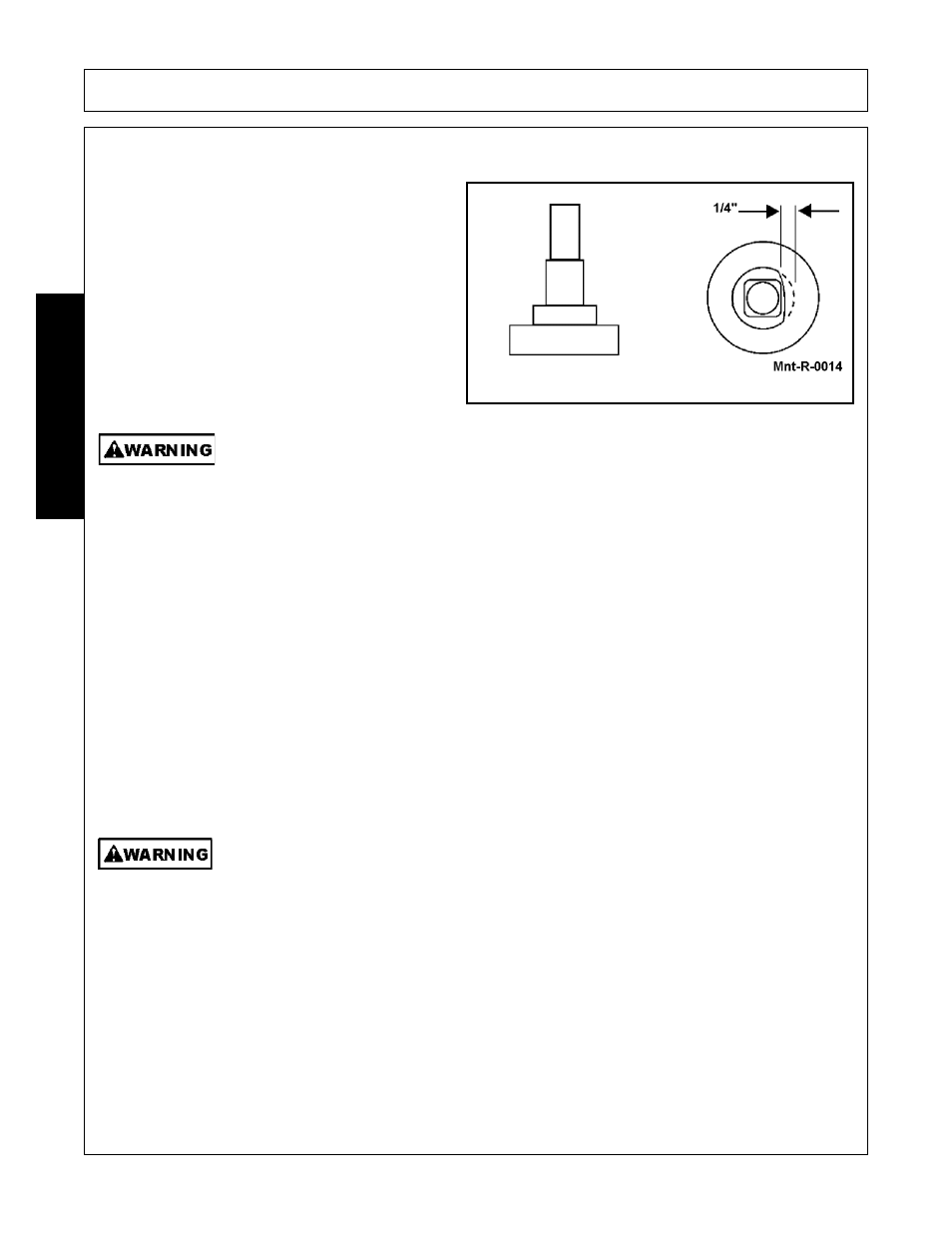

BLADE REMOVAL

To remove blades for sharpening or replacement,

remove the cover plate on deck of cutter near gear

box. Remove lock nut from blade bolt. NOTE:

Inspect lock nut after removal and replace if threads

are damaged. Always replace nut when replacing

blade bolt. When installing blades be sure and

check blade bolt pivot diameter for wear. Replace

bolt if worn more than 1/4 inch at any point. Install

blade bolts with partially worn side of bolt away from

center. Tighten lock nut to 350 ft. lbs.

Avoid personal injury. Blade and/or blade carrier removal should be done only with the

tractor engine shut off, key removed, in neutral, parking brake on, and PTO disengaged and

the cutter blocked in the raised position.

BLADE CARRIER REMOVAL

Remove cotter pin and loosen slotted nut on gearbox shaft. Loosen but do not remove the nut until the blade

carrier is loosened. Use a suitable 2 jaw gear puller to pull carrier off tapered gearbox shaft. If gear puller is not

available use long bar inserted through blade bolt access hole with end against rotor bar. Strike opposite end of

bar with sledge hammer. Rotate blade carrier 180 degrees and repeat process until carrier breaks loose.

BLADE CARRIER INSPECTION

Blade bolt fit into carrier bushings should be checked every time blades are changed. The blade bolt should fit

into carrier bushings as a snug slip fit. If the blade bolt fit appears to be loose or sloppy, measure the square

hole in bushing. If the bottom of the square hole is 1/16” or greater than the square shoulder of the new blade

bolt the bushings should be replaced. Bushings can be removed by cutting bushing head where it is welded to

carrier bar. Once head is removed bushing can be pressed out of bar. Clean and grind top of blade bar so new

bushing can be installed and welded. Bushing should be pressed into bar so that bottom of bushing is flush

with bottom of blade bar. Use low hydrogen rod to weld bushing in place.

Failure to replace a worn blade carrier bushing as described above may lead to catastrophic

failure of the blade, blade bolt, and/or blade bolt nut resulting in the ejection of the broken

parts out from under the mower at tremendous speed and force which could result in serious

bodily injury or death.