Super, Regulating the machine – Dake Model Super Technics 350SA User Manual

Page 9

9

SUPER

SUPER

SUPER

SUPER

SUPER TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

CUTTING CYCLE:

-

Vice locking;

-

Head downfeed;

-

Head lifting;

-

Vice opening;

-

Material feeding.

- Ensure that the machine is not in emergency stop condition; if

it is, release the red mushroom button ( 1 ).

- Make sure that the connection to the pneumatic system has

been carried our according to the chapter 7 paragraph 7.7.

- Ensure that the selector ( 8 ) is in "MANUAL" mode.

- Turn the main switch ( 3 ) in position ON.

- Press the start/reset button ( 2 ): its green light will go on.

- Select the cutting speed on the switch ( 4 ):

position 1 = 22 rpm

position 2 = 44 rpm

- Set the number of pieces to be cut on the piece-counter (10)

(see chapter 7 paragraph 7.5).

- Set the number of feed repetition on the feed repeater (11)

just in case the cutting length required is longer than the

mechanical stroke of the feeding system (see chapter 7

paragraph 7.6). Note: set “1” if no feed repetition is required.

- Place material to be cut in the vice. Close jaws against

piece,keeping a distance of approx. 3 - 4 mm.

- Adjust the cutting stroke by means of the selector ( 5 )

approaching the blade upto 10 mm from the workpiece. Position

the relevant mechanical endstroke.

- Set the required cutting length (

see chapter 7 para. 7. 8 ).

- Adjust the vice of the feeding system (

see chapter 7 para.

7.10 ).

- Set the blade downfeed speed on the regulatorì according to

the specifications of the workpiece.

- Press Cycle Start and verify the following functions:

vice clamping, blade rotation anticlockwise, coolant liquid flow

and cutting cycle execution.

Turn the selector ( 8 ) to the "AUTOMATIC" mode while the

machine is performing the initial cutting cycle end press the

push button ( 9 ) . The machine will feed the material to the

preset cutting length.

- The machine will go on performing more cutting cycles as

long as the material to be cut is finished.

- In case of wrong operation press Emergency Push-button

( 1 ).

REGULATING

THE

MACHINE

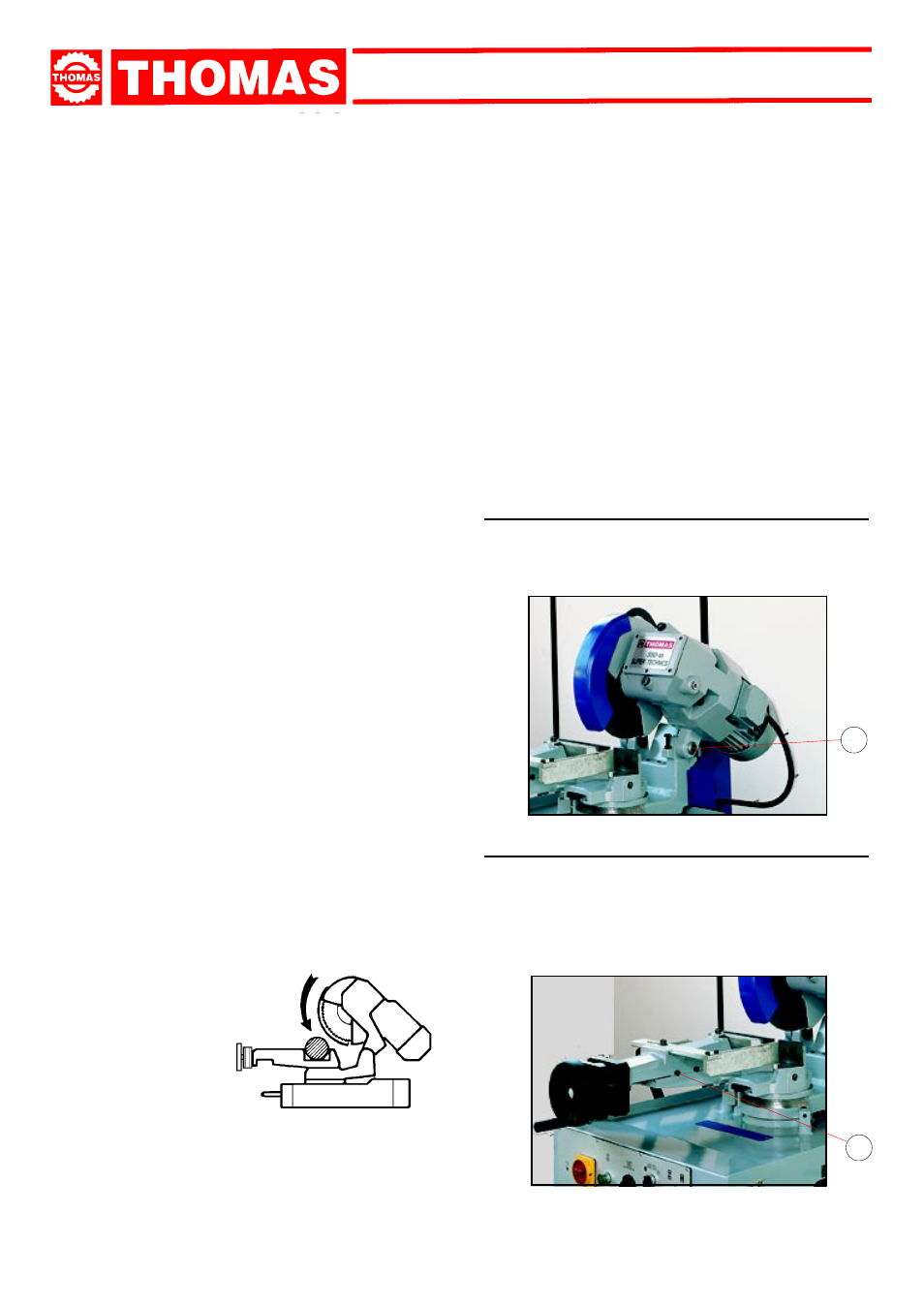

7.1 - Cutting head

- If excessive axial play is found on the hinge, it will be sufficient

to tighten the ring nuts ( A ), paying attention not to make the

joint too tight.

7.2 - Vice

- The device does not require any particular adjustment; in the

event of excessive play in the sliding guide, tighten the dowels

( B ) for adjusting the gib inside the slide.

- Approach the vice jaw upto 4-5mm from the material to be

cut.

- When starting to cut with a new disk, in order to safeguard

its life and efficiency, the first two or three cuts must be

made while exerting a slight pressure on the part, so that

the time taken to cut is about double the normal time (see

below in the chapter on “Material classification and choice

of disks” in the section on

Running in the disk).

- Press the red emergency button ( 1 ) when there are conditions

of danger or malfunctions in general, so as to stop machine

operation immediately.

7

CUTTING DIRECTION

The cropper is now ready to start work, bearing in mind that the

CUTTING SPEED and the TYPE of DISC - combined with a

suitable descent of the head - are of decisive importance for

cutting quality and for machine performance (for further details

on this topic, see below in the chapter on “Material classification

and choice of disks”).

A

B