Super – Dake Model Super Technics 350SA User Manual

Page 11

11

SUPER

SUPER

SUPER

SUPER

SUPER TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

7.6 - Feed repeater

- You can set the number of feed repetition on the feed repeater

just in case the cutting length required is longer than the

mechanical stroke of the feeding system.

Set “1” if no feed repetition is required.

- Take into account the blade thickness and set the mechanical

stroke of the feeding system accordingly.

For example:

In case you need 1500mm cutting length

1500 - 6

= 498

3

1500 = cutting lenght.

6

= blade thichness ( 3 x 2 )

3

= number of required feeding runs

498 = this is lenght the feeding stroke must be set to on the

metric scale .

11

13

12

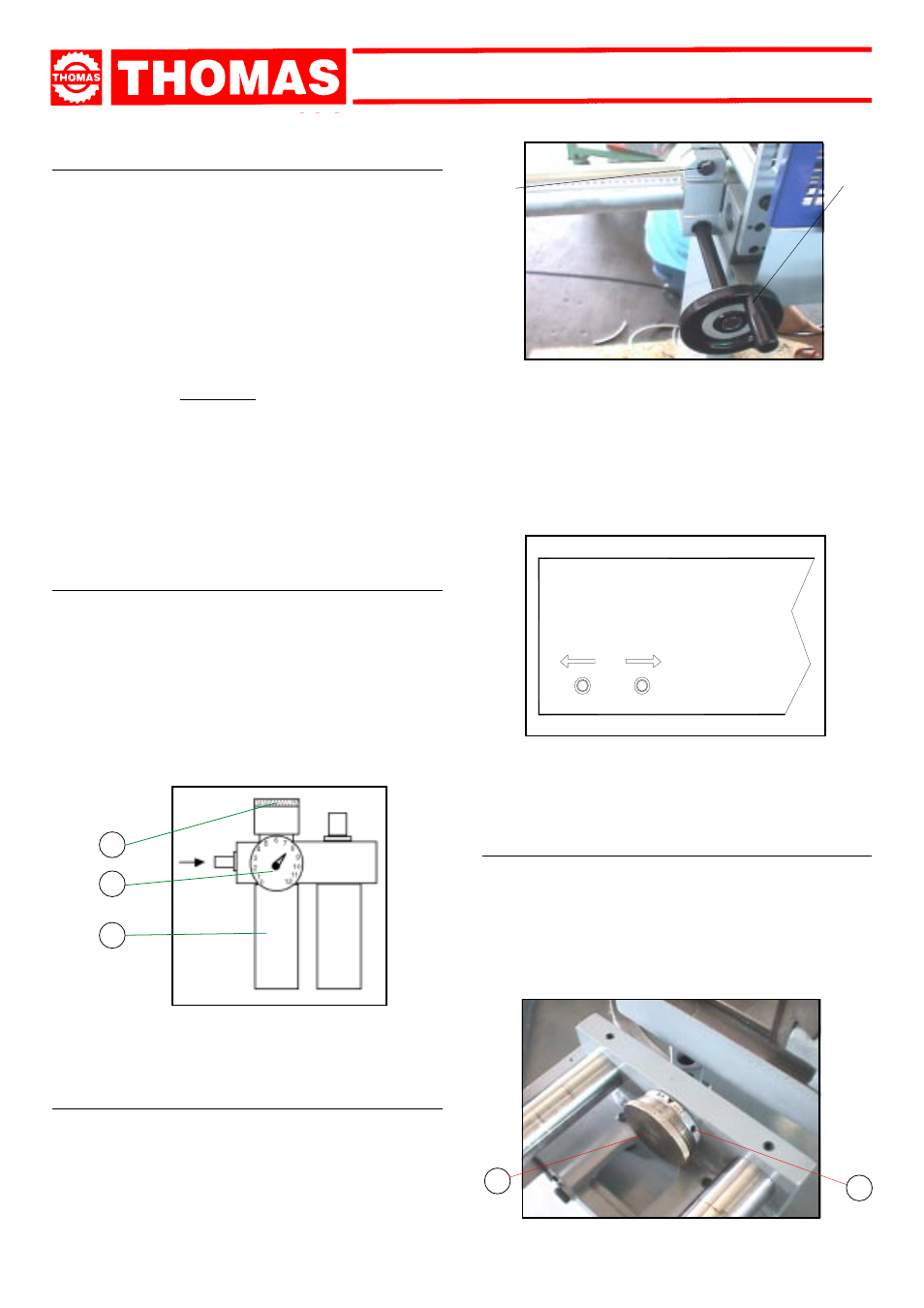

7.7 - Adjustment of pneumatic system pressure

- The pressure in the pneumatic system necessary for the proper

operation of the sawing machine must be equal to 6 - 7 Bar.

- Check on pressure switch (11) the exact correspondence and

if necessary operate on regulator (12) to set the ideal pressure.

- Make sure that a drop of oil runs through the lubricator bulb

( 13 ) every 4/5 work cycle.

7.8 - Adjustment of cutting length

- Proceed as follows to adjust the cutting length:

- Loose screw ( A ).

- Turn handwheel ( B ) to set the required cutting lentgh on the

metric scale.

- Lock screw ( A ).

A

B

7.9 - Decimal adjustment

- This is a fine cutting length adjustment by means of a Vernier

(14).

- Release the screw (15) and turn the vernier as much as you

need with reference to the engraved marks.

- One mark is 0.05mm (metric system).

- One mark is 1/500 of a inch (English system)

- Lock the screw (15).

15

14

- Set the regulators A = forward

I = backward

to absorbe the mechanical stop of the feeding system

during the cutting cycle.

A

I