Super – Dake Model Super Technics 350SA User Manual

Page 12

12

SUPER

SUPER

SUPER

SUPER

SUPER TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

1

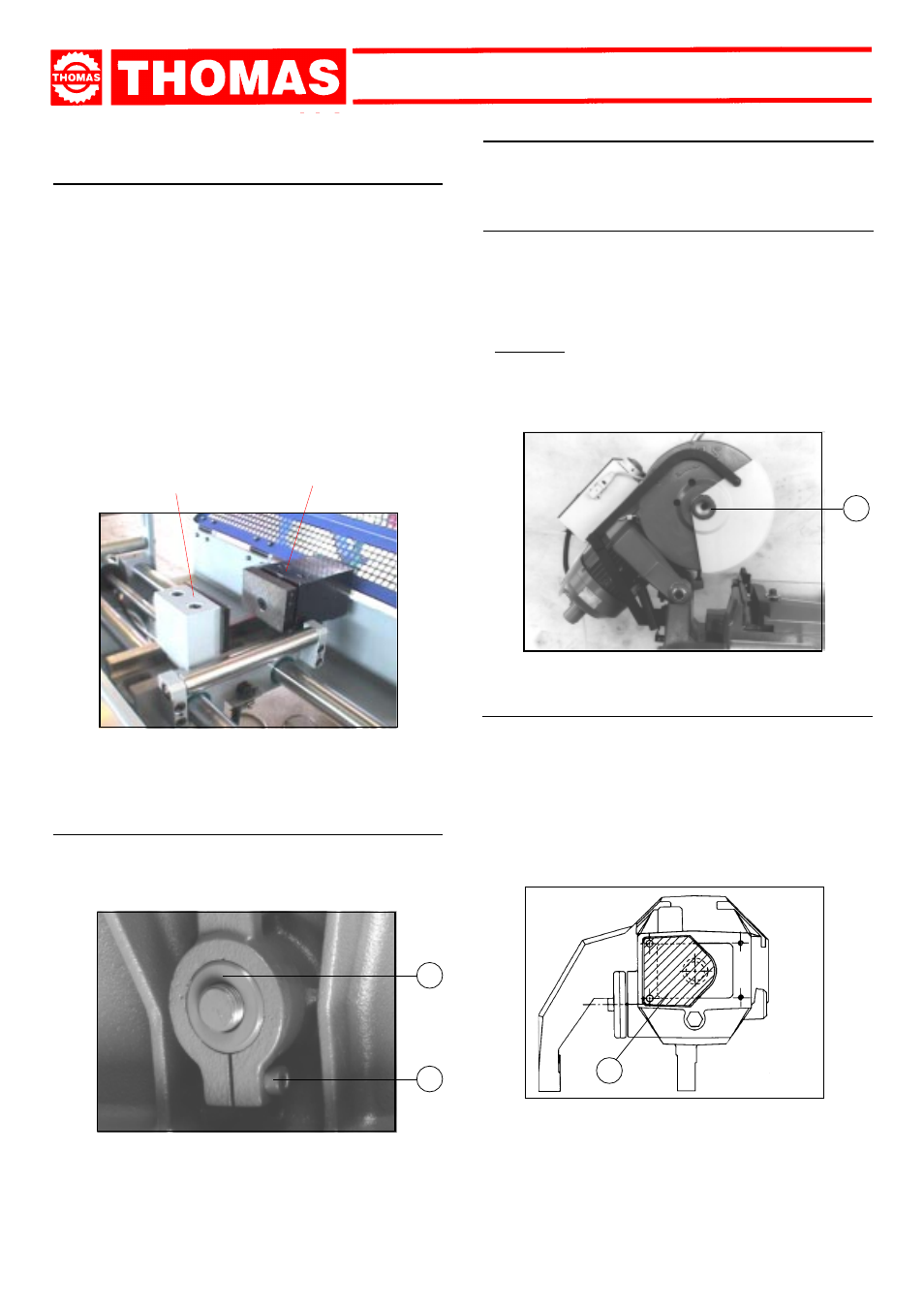

7.13 - Clutch adjustment

Inside the head there is a clutch device which has already been

adjusted during assembly. If, after long use, further adjustment

is necessary, proceed as follows:

- remove the cover

- fit the template provided

- turn the motor shaft so that the ring nut ( 1 ) is in a convenient

position to allow it to be tightened or slackened enough to

calibrate the clutch system.

ANY REPLACEMENTS OF OTHER PARTS - SUCH AS THE

COMPONENTS OF THE REDUCTION GEAR, MOTOR AND

VARIOUS ELECTRIC PARTS - MUST BE CARRIED OUT BY

SKILLED OR COMPETENT PERSONNEL.

7.11 - Regulating arm blockage

- If there is insufficient blockage of the head arm in the desired

position, slacken the screw ( 1 ) on the lever, hold the bush

( 2 ) in position, turn the lever to the left and tighten the screw.

1

2

BEFORE PERFORMING THE FOLLOWING OPERATIONS,

THE ELECTRIC POWER SUPPLY AND THE POWER CABLE

MUST BE COMPLETELY DISCONNECTED.

7.12 - Changing the disk

To change the disk:

- Release the mobile yellow, white or orange guard and turn it

back.

- Block a piece of wood in the vice and lean the disk on it.

- Insert the special spanner provided and remove the screw

( 1 ), slackening it in a clockwise direction because it has a

left-handed thread, then slip off the flange that holds the disk.

- Fit the new disk, checking the cutting direction of the teeth,

then replace the flange, the screw and the mobile white, yellow

or orange guard.

1

7.10 - Adjusting the feeding system

- Adjust the feeding vices as follows:

- Load the workpiece and clamp it in the bench vice by means

of the relevant handwheel.

- Loose the vice screw ( C ), approach the relevant jaw upto 4-

5 mm from the material to be cut. Tight the screw.

- Loose the vice screw ( D ), approach the relevant jaw upto

0,5 mm from the material to be cut. Tight the screw.

NOTE: carefully adjust the vices ( C ) and ( D ). On the

contrary, the microswitch controlling the presence of the

workpiece will stop the machine.

- Loose the bench vice allowing 4-5mm clearance from the vice

jaw and the workpiece.

C

D