Super, Routine and special maintenance – Dake Model Super Technics 350SA User Manual

Page 13

13

SUPER

SUPER

SUPER

SUPER

SUPER TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

TECHNICS 350 SA

- Remove the connecting plug from the electric box and un-

screw the head moving lever.

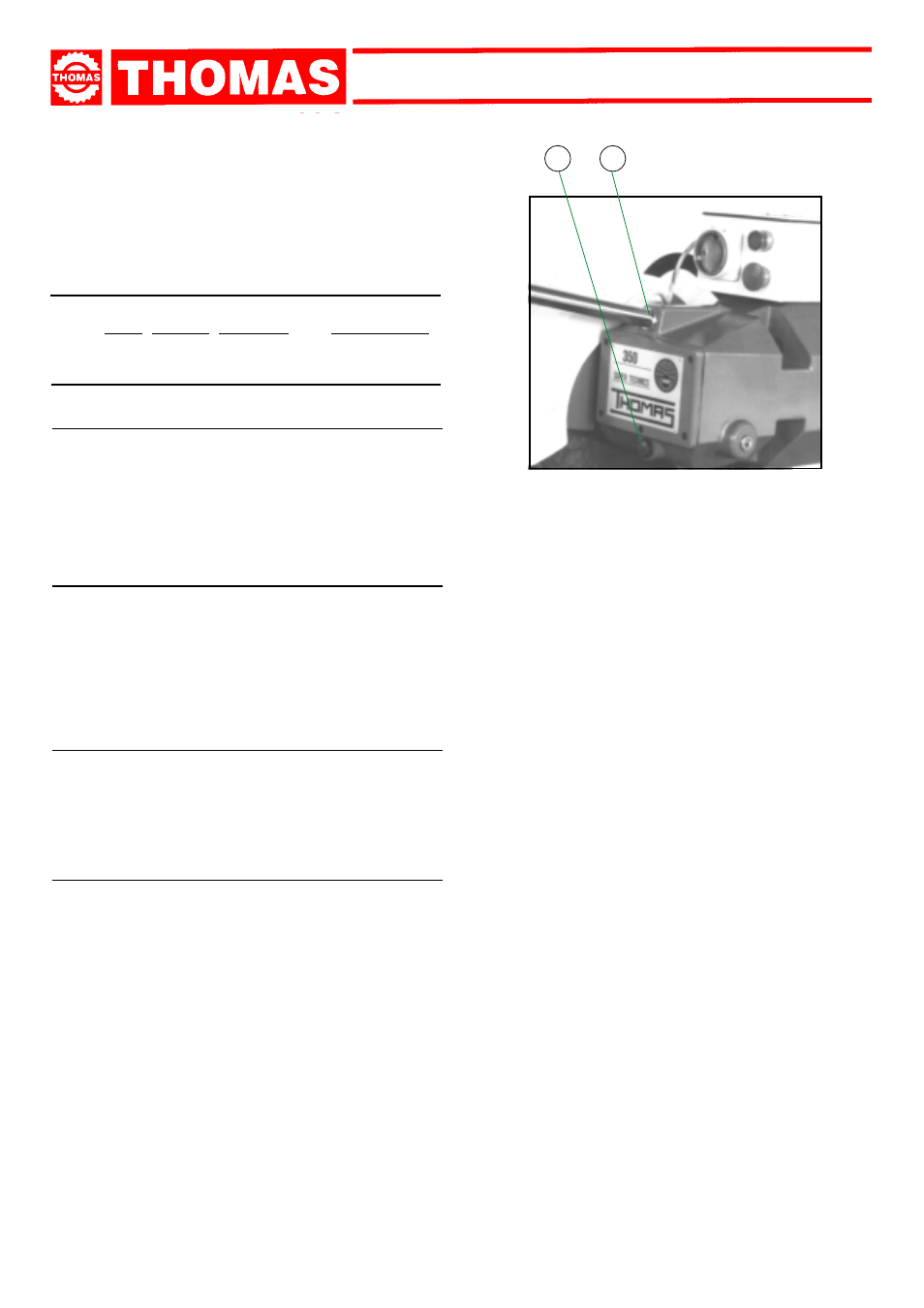

- Drain off the old oil from the cap ( 1 ).

- Pour in new oil up to the mark ( 1 ), through the lever fixing

hole, keeping the head in upper position ( 2 ).

- Reassemble all the parts.

- Check continuity of the equipotential protection circuit

2

1

ROUTINE

AND SPECIAL

MAINTENANCE

THE MAINTENANCE JOBS ARE LISTED BELOW, DIVIDED

INTO DAILY, WEEKLY, MONTHLY AND SIX-MONTHLY

INTERVALS. IF THE FOLLOWING OPERATIONS ARE

NEGLECTED, THE RESULT WILL BE PREMATURE WEAR

OF THE MACHINE AND POOR PERFORMANCE.

8.1 - Daily maintenance

- General cleaning of the machine to remove accumulated

shavings.

- Top up the level of lubricating coolant.

- Check the disk for wear.

- Lift the head into a high position to avoid yield stress on the

return spring.

- Check functionality of the shields and emergency stops.

8.2 - Weekly maintenance

- More accurate general cleaning of the machine to remove

shavings, especially from the lubricant fluid tank.

- Clean the filter of the pump suction head and the suction

area.

- Clean and grease the screw and the sliding guide of the vice.

- Clean the disk housing.

- Sharpen the disk teeth.

8

8.3 - Monthly maintenance

- Check tightness of the screws on the motor, the pump, the

jaws and shields.

- Check that the shields are unbroken.

- Grease the head hinge pin.

8.4 - Six-monthly maintenance

- Change the oil in the reduction unit using oil type GEARCO

85W-140 by NATIONAL CHEMSERACH or MOBIL GLYCOLE

30 or KLUBER SINTHESO 460 EP or an equivalent oil,

proceeding as follows: