Periodic maintenance, Storage, Specifications – Summers 84' Superroller User Manual

Page 36: Storage & specifications -2

4-2

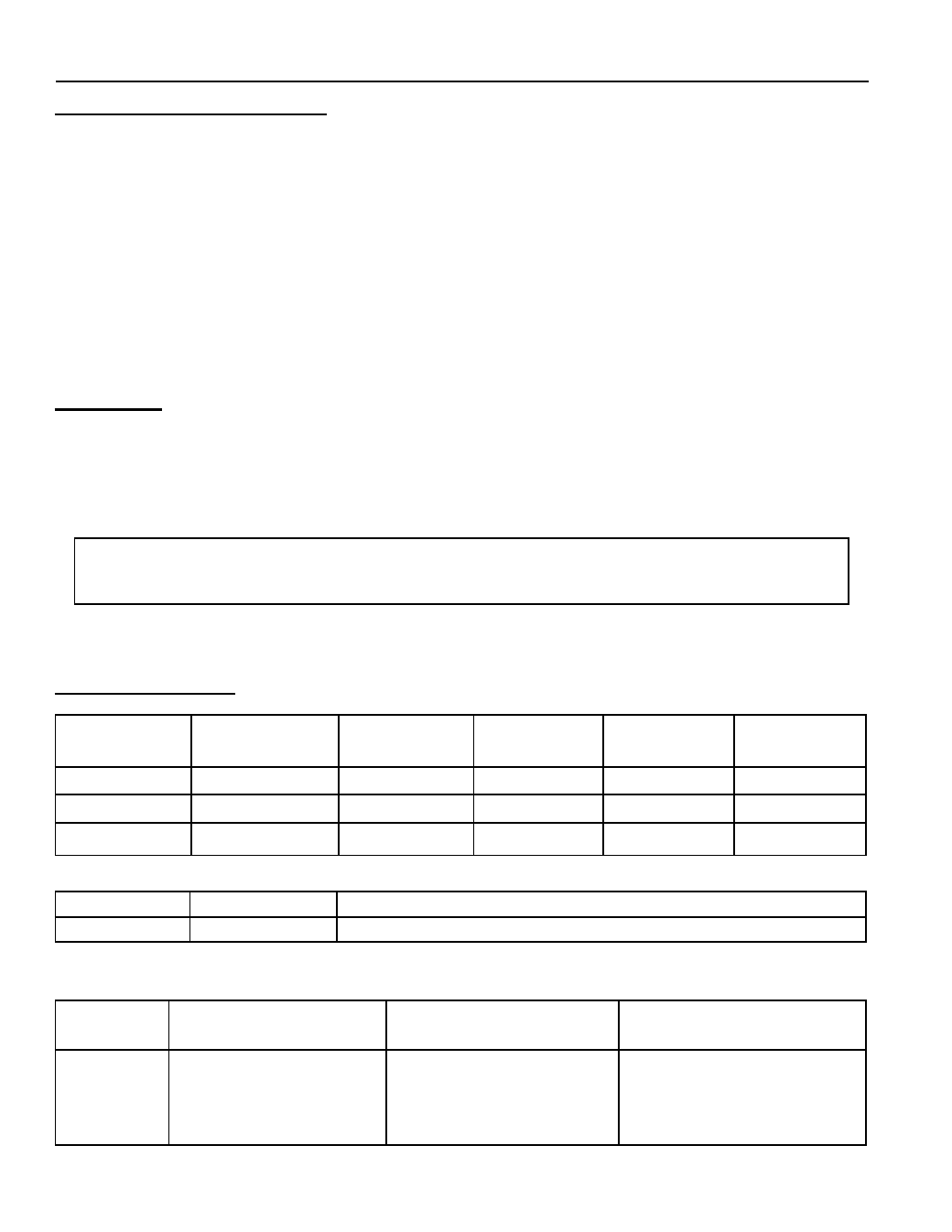

SPECIFICATIONS

Working Transport Transport Transport Machine

Roller

Width

Width

Height

Length Weight Diameter

62’

17’3”

6’0”

56’10” 35,600# 42”

84’

17’3”

6’0”

67’10”

42,400#

42”

84’

17’3”

6’0”

67’10” 38,000# 36”

Tire Size

Rating

Recommended Inflation Pressure

12.5Lx15

LRF

90 PSI

Hub Size

Rating

Recommended Wheel

Recommended Axle

Nut Torque

Nut Torque

HD812

6100 LB.

170 ft.-lbs.

45 ft.-lbs., loosen until

20 MPH Maximum

first slot is aligned with

hole in axle, install cotter

pin, bend to retain.

PERIODIC MAINTENANCE

Caster Wheel Pivot Lock Adjustment

The pivot lock cylinders will require periodic adjustment. With the pivot lock cylinder retracted, adjust

the lock pin so it is 1/8” inside the lock collar as shown on Page 3-5.

Grease all zerks shown in the diagram daily.

Check tightness of castle nuts and all component of the caster wheel.

1. Repack wheel bearings and check tightness.

2. Check the tightness of all hardware. Pay special attention to hitch and pivot pin retaining bolts.

3. Check Land Roller for damaged or worn parts. Replace as needed.

STORAGE

1. Follow steps outlined in “UNHOOKING LAND ROLLER FROM TRACTOR IN FIELD POSITION”.

2. Clean and remove all excessive dirt and grease from Land Roller.

3. Grease all zerks.

4. To prevent rusting, repaint any areas that have been worn, chipped or scratched.

5. Apply grease* to any exposed part of cylinder shafts.

*NOTE: Before returning Land Roller into service, all grease must be removed from cylinder

shafts to prevent damage to seals.

SECTION 4 – MAINTENANCE