Section 4 - maintenance, Safety, After first 4 hours of operation – Summers 84' Superroller User Manual

Page 35: Daily maintenance, Maintenance safety

SECTION 4 – MAINTENANCE

SEC2-WHEEL

12/9/2009

9LR6242.iam/

A

8X0072

1/2" X 3-3/4"

8K1105S

8X0242

NY-LOCK 1/2" N

8K7042

8P7160L

8X0261

3/4" LN

8X0284

1 1/4" N

8X0311

1 1/4" LW

8L0252

8X0122

8D9108

1/4 X 2" RP

8X0286

1 1/2" JN

8X0292

2" SLTD N

7P8530

8X0320

3/8" FW

8X0202

3/8" LN

8K5200

7L2150

8L0320

8X0260

3/4" N

8X0306

3/4" LW

8P0302

8P7200

8K9102

8D9108

1/4 X 2" RP

8K1723

8X0114

3/4 x 3"

8X0306

3/4" LW

8X0260

3/4" N

8P7190B

8X0368

1-1/2" FW

8P7250

4-1

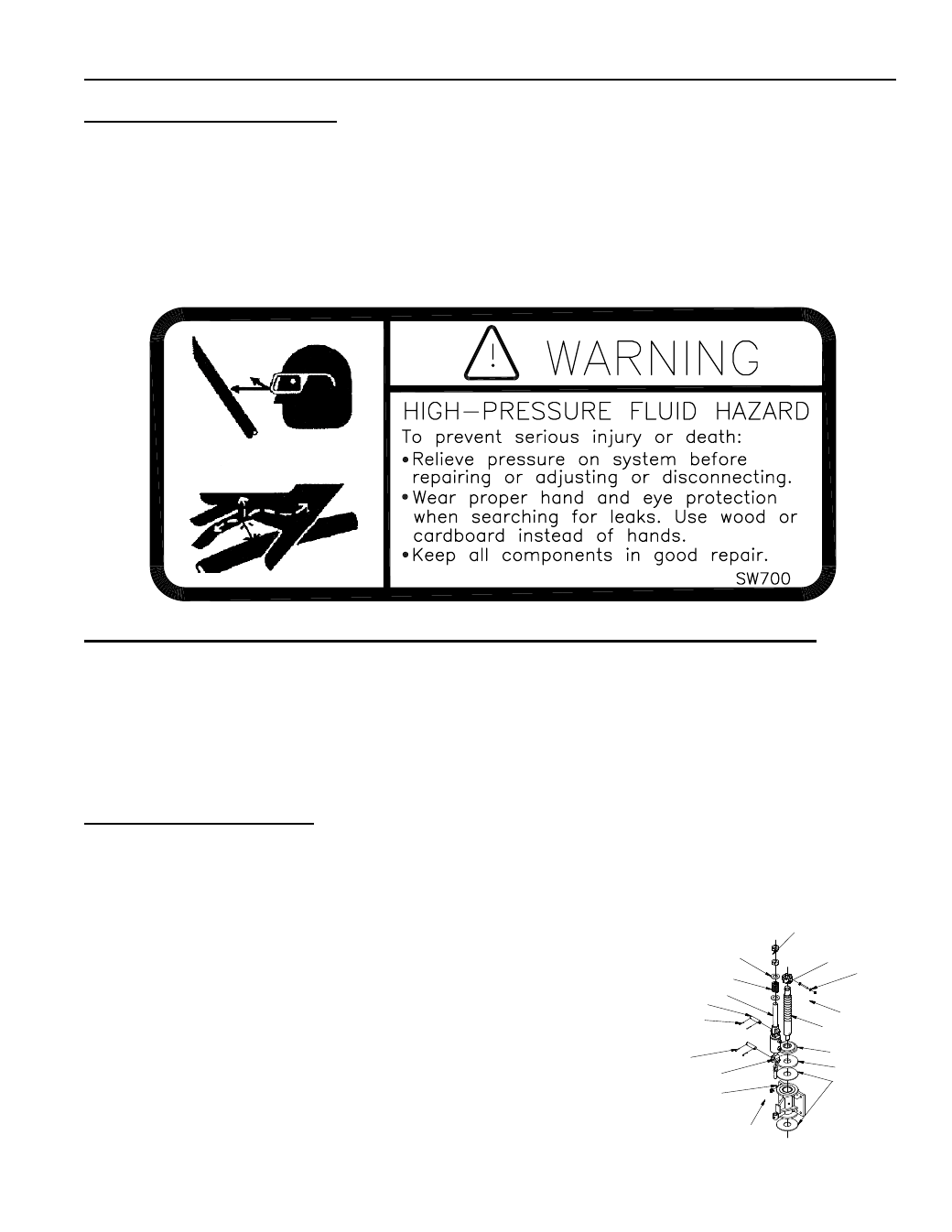

MAINTENANCE SAFETY

1. STOP engine, place all controls in neutral, set parking brake, remove ignition key and wait for all

moving parts to stop before servicing, adjusting or maintaining.

2. BE CAREFUL when working around high pressure hydraulic system.

3. ALWAYS make sure that Land Roller is lowered into field position, it is blocked to prevent move-

ment and pressure is relieved from hydraulic circuits before servicing.

4. USE EXTREME CARE when making adjustments.

5. KEEP CHILDREN AWAY from machinery at all times.

6. NEVER ALLOW anyone to work under Land Roller.

MAINTENANCE FOR AFTER THE FIRST FOUR HOURS OF OPERATION

1. Grease wing and hitch pivots.

2. Check all hydraulic components for leaks. (SEE HIGH-PRESSURE FLUID WARNING ABOVE.)

3. Check tightness of wheel nuts. Recommended torque 170 ft. lbs.

4. Check tightness of wheel bearings.

5. Check tightness of all hardware. Pay special attention to hitch and pivot pin retaining bolts.

6. Check tire pressures. Recommended air pressure is 90 PSI.

DAILY MAINTENANCE

1. Grease wing and hitch pivots.

2. Check all hydraulic components for leaks. (SEE HIGH-PRESSURE FLUID WARNING ABOVE.)

3. Check tightness of all wheel nuts. Recommended torque 170 ft. lbs.

4. Check tire air pressure. Recommended air pressure is 90 PSI.

BALL BEARINGS ON ROLLERS: To maximize bearing life, grease

bearings at mid day or end of day when bearings are at operat-

ing temperature.

Every 20 hours: Add three strokes (approx.

.14 oz.) of grease.

CASTER MAINTENANCE: Castle nut on the caster needs to be

checked daily for tightness using the following procedure:

Tighten the Caster Castle nut so the caster assembly cannot be

turned by human force. Install the hardware in the castle nut as

shown to ensure that it will not loosen.