Transporting, Caster wheel pivot lock operation & adjustment, Transporting -5 – Summers 84' Superroller User Manual

Page 33: Transporting land roller

SECTION 3 – OPERATION

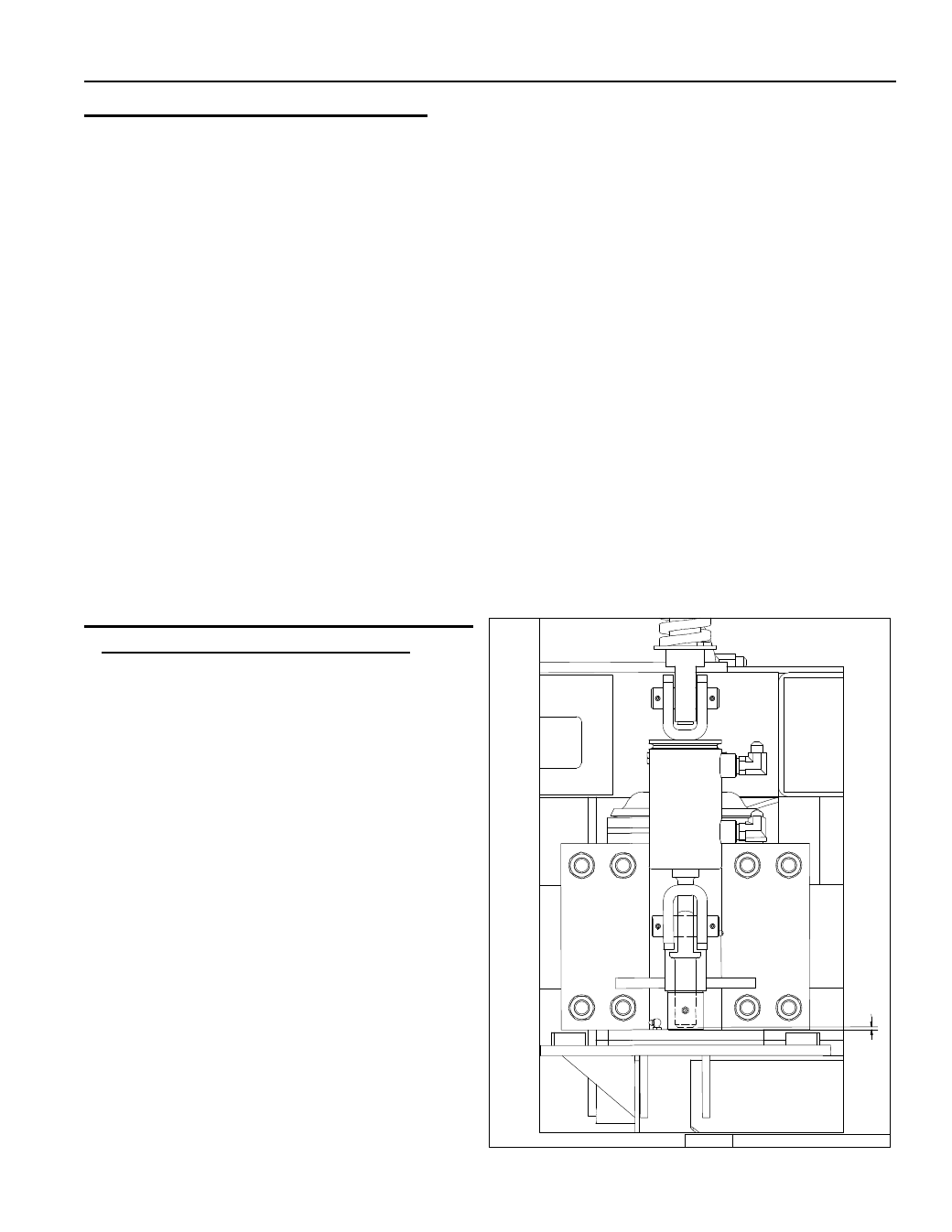

Pivot Lock Cylinder

9/21/2010

9LR6242.iam/

1/8"

3-5

TRANSPORTING LAND ROLLER:

1. If Land Roller is in Field Position, follow “Steps Required to Fold Land Roller from Field to Trans-

port Position”, page 3-4.

2. Ability to safely operate the Summers Superroller is determined by both tractor horsepower and

weight. The minimum tractor weight for operating this implement is 30,000 lbs. Minimum tractor

engine horsepower is 300. Dual tires or single tires set at maximum width are required for safe

operation of Land Roller.

3. ONLY TOW at a safe speed – 20 MPH MAXIMUM. Use caution when making corners or meet-

ing traffic.

4. USE Safety Lights and Safety Chain between tractor drawbar and implement hitch when trans-

porting on public roads.

5. ALWAYS install lift cylinder locks.

6. FOLLOW ALL local laws governing transporting of farm machinery.

7. Use additional caution and reduce speed when towing under adverse conditions, when turning

and when on unlevel surfaces.

8. Stay clear of overhead lines and other overhead obstructions.

9. Frequently check for traffic from rear, especially during turns.

CASTER WHEEL PIVOT LOCK

OPERATION & ADJUSTMENT:

The caster wheel pivot lock has been de-

signed to provide tension to the caster wheel as-

sembly. This tension will help to provide stability

to the caster wheel at transport speed. When

transporting the machine the pivot lock cylinder

should be extended when traveling in a straight

forward direction.

When turning the machine around corners

or into fields the pivot lock cylinders should be

retracted to allow the caster wheel to rotate.

The pivot lock cylinders should be extended as

soon as the turn is completed and before speed

is increased.

The pivot lock cylinders will require periodic

adjustment. With the pivot lock cylinder retracted,

adjust the lock pin so it is 1/8” inside the lock

collar as shown.

Failure to comply with the above recom-

mendations can result in damage to the

machine which will not be covered under

warranty.