American Dryer Corp. Gas HSI - Phase 7/FSS AD-78 III User Manual

Page 30

26

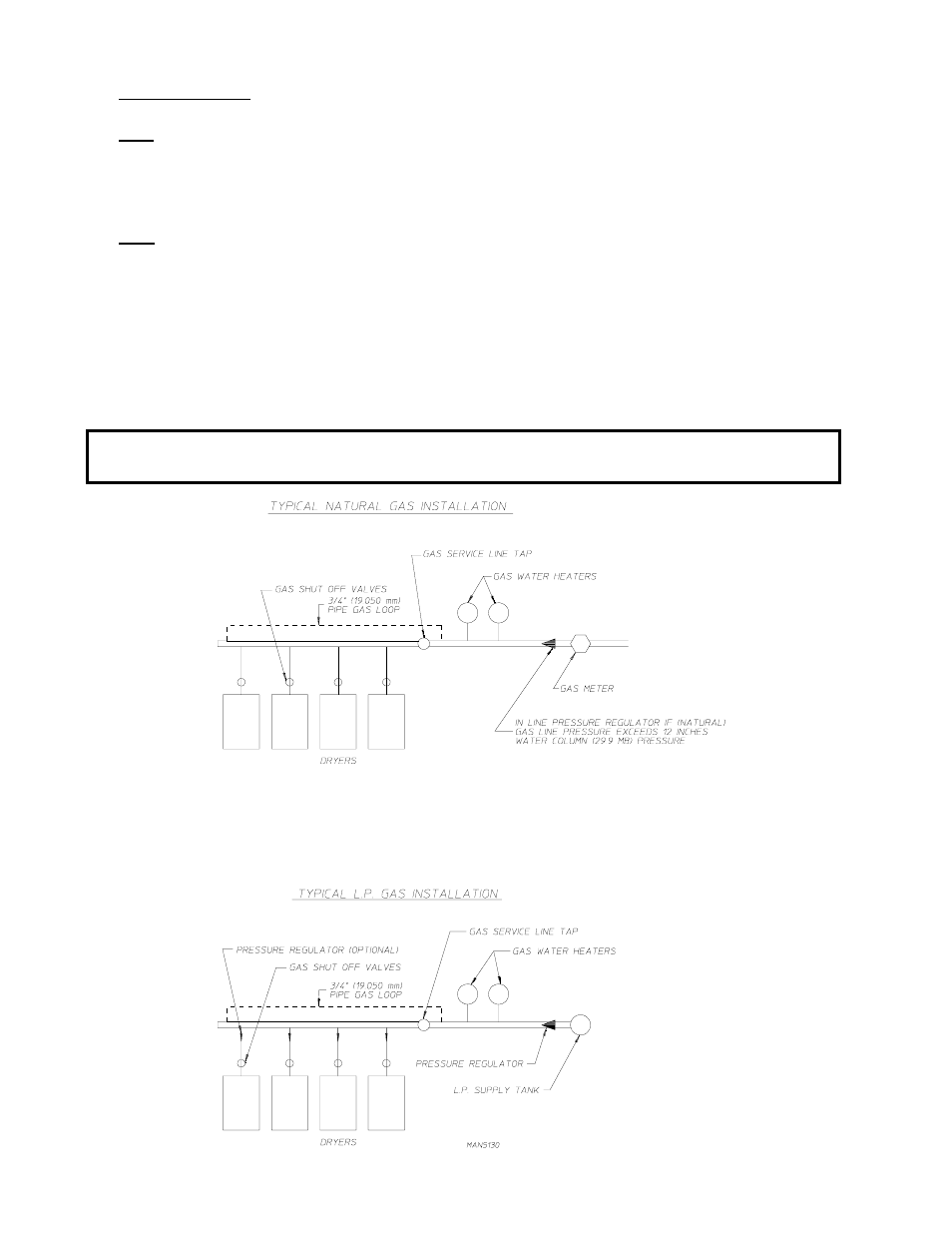

3. Piping/Connections

ALL components/materials must conform to National Fuel Gas Code Specifications ANSI Z223.1-LATEST

EDITION, or in Canada, CAN/CGA-B149.1-M91 (Natural Gas) or CAN/CGA-B149.2-M91 (Liquid

Propane [L.P.] Gas) or LATEST EDITION (for General Installation and Gas Plumbing), as well as local

codes and ordinances and must be done by a qualified professional. It is important that gas pressure

regulators meet applicable pressure requirements, and that gas meters be rated for the total amount of

ALL the appliance BTUs being supplied.

The dryer is provided with a 3/4 N.P.T. inlet pipe connection located at the right side of the base of the

dryer. The minimum pipe size (supply line) to the dryer is 3/4 N.P.T. For ease in servicing, the gas supply

line of each dryer must have its own shutoff valve.

The size of the main gas supply line (header) will vary depending on the distance this line travels from the

gas meter or, in the case of L.P. gas, the supply tank, other gas operated appliances on the same line, etc.

Specific information regarding supply line size should be determined by the gas supplier.

NOTE: Undersized gas supply piping can create a low or inconsistent pressure, which will result in

erratic operation of the burner ignition system.