Equipment return, Diagnostics and symptoms, Gain control – AMETEK 7330 Pro-Stik II User Manual

Page 8: Manual setting of gain, Optional push button setting of gain, Additional information

8

Equipment Return

In order to provide prompt and reliable service, any

equipment being returned for repair or credit, must be

pre-approved by the factory.

You must have a Returned Material Authorization

Number! To obtain a Returned Material

Authorization (RMA#), contact your distributor.

Please provide the following information:

•

Model Number of returned equipment

•

Serial Number

•

Original Purchase Order Number

•

Detailed description of the failure

•

Contact Name and Phone Number

In many applications, the probes are exposed to

hazardous materials. It is your responsibility to fully

disclose all chemicals and decontaminate the entire

product.

•

OSHA mandates that our employees be informed

and protected from hazardous chemicals.

•

A

Material Safety Data Sheet (MSDS) listing any

hazardous material to which the probe has been

exposed

MUST accompany any return.

Gain Control

The internal signal gain is set at the factory and should

not need to be adjusted in the field. However, if the

output signal is unstable (i.e. the output goes to 3.8mA

with the float in place), or the probe is being applied in

a high temperature application, the internal signal gain

may be re-set as follows:

Manual Setting of Gain

1. Place the float near the end of the probe.

2. Power down the probe.

3. Short the White “program” wire to the Black “Loop –”

wire and apply power with the wires shorted.

4. Output goes from 12mA to 20mA if successful.

5. Output will go to 3.8mA if gain setting failed.

6. Power down the probe and remove the short

between the White “program” wire and the Black

“Loop –” wire.

Diagnostics and Symptoms

1. Float magnet is outside of the programmed span

a. Beyond 4mA set point is indicated as 3.9mA.

b. Beyond 20mA set point is indicated as 20.1mA.

2. Loss of signal, sensor failure, or float outside active

range (top or bottom) is indicated as 3.8mA.

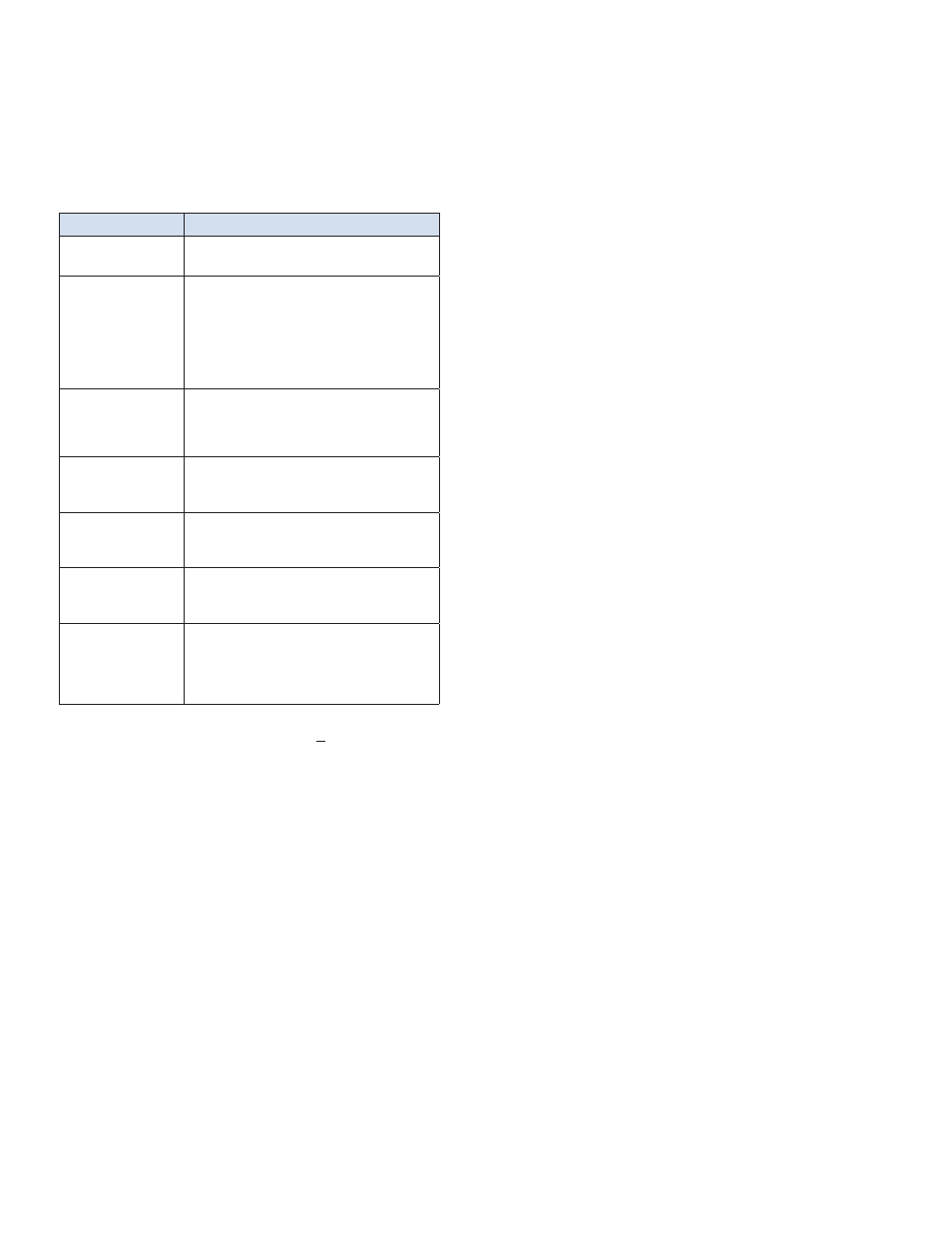

Symptom

Troubleshooting Tip

No signal received at

controller

• Check that power is applied to controller

• Check wiring connection to probe

Output is 3.8mA

• Be sure float retention clip is in place at base of

probe and float is installed

• Be sure float is in active region and not stuck in Null

or Dead Zone

• Reset Gain

• Check temperature of process. Cannot be greater

that 230ºF (110ºC)

Output appears erratic

• Be sure probe is mounted perpendicular with

gravity

• Check float for free movement along probe

• Reset Gain

Output appears to be

going down, yet tank

is filling

• Check configuration of 4mA & 20mA points

Output appears to be

going up, yet tank is

emptying

• Check configuration of 4mA & 20mA points

Output is not scaled

properly

• Re-set both Zero (4mA) and Span (20mA) points.

Panel Meter error

• Check to see if the panel meter being used is

“confused” by an output of less than 4mA or more

than 20mA. 3.9mA, 3.8mA or 20.1mA are diagnostic

outputs and should be used for alarms.

(All diagnostic values with tolerances +0.02mA)

7. Apply power, the probe will return in normal 4 to

20mA mode with the new gain set.

8. If the signal does not return to normal, and the

problem was not solved, contact your distributor.

Optional Push Button Setting of Gain

1. Place the float near the end of probe.

2. Power down the probe.

3. Hold down the Zero button and apply power.

4. Output goes from 12mA to 20mA if successful.

5. Output will go to 3.8mA if AGC failed.

6. Power down the probe and release the Zero button.

7. Apply power, the probe will return in normal 4 to

20mA mode with the new gain set.

8. If the signal does not return to normal, and the

problem was not solved, contact your distributor.

Additional Information

See addendum information for sanitary and flex probe

installation instructions.

7330 Sanitary 3A Probes Data Sheet Z157

7330 316 Stainless Steel Probes Data Sheet Z154

7330 PVDF Flex Probes Data Sheet Z177

Flex Probe Installation & Handling Procedure Z190