Installation of pvdf probe – AMETEK 7330 Pro-Stik II User Manual

Page 4

4

Installation of PVDF Probe

CAUTION:

NOTE: The apparatus contains exposed

non-metallic surfaces considered to

constitute an electrostatic discharge

hazard. Clean only with a damp cloth.

Also, refer to separate Flex Probe Installation &

Handling Procedure document Z190 which is shipped

with the probe.

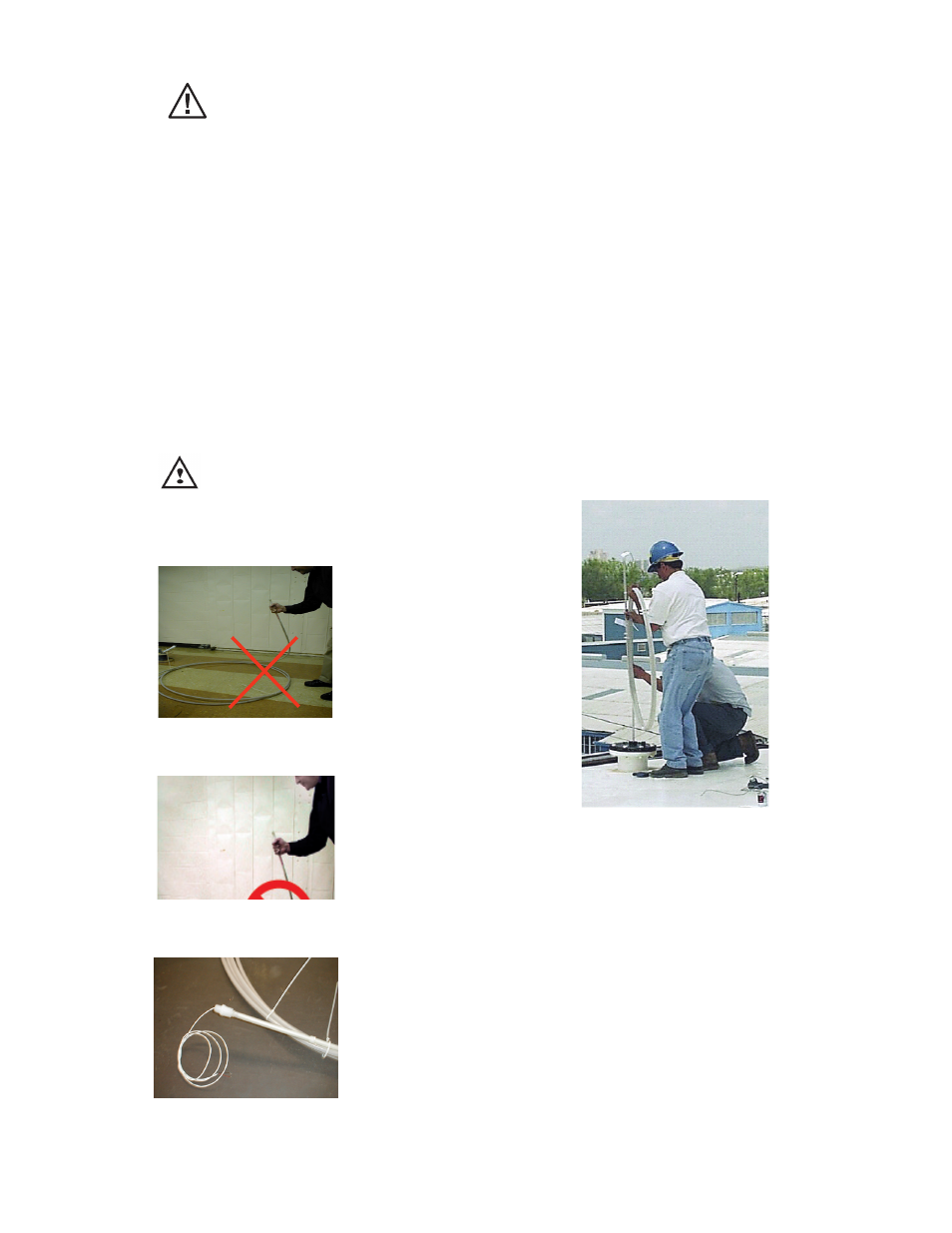

Assembly is basically the same as for the steel probe.

However, two people are recommended for assembly

of the 7330 Flex Probe; one to hold the probe and the

other to assemble components.

During unpacking and installation, always keep the

coils parallel. Do not let the diameter of the coils

become less than 40 inches (approx. 1 meter).

CAUTION

Kinking a probe is considered user damage

and NOT covered by warranty!

DO NOT bend top of probe!

DO NOT support probe by electrical cable!

1. Using a side cutter, cut the tie wrap at the end of

the probe.

2. Slide reducing bushing or flange (supplied by

customer) on for Style D probe.

3. Slide float onto probe. On a symmetrical steel float,

the magnet is located in the middle of the float, so

orientation does not matter.

4. Slide weight or spacer on the probe and capture all

of these parts with the SS pin.

NOTE: The span is set at the factory, however, if

it is necessary to adjust or reset the span before

installation, refer to the section on Setting the Span

first, then two people should uncoil the probe in a flat

area the length of the probe. Cut one tie wrap at a time

in sequence. When recoiling the probe, be careful to

keep the coils parallel and not to let the diameter of the

coils become less than 40 inches (approx. 1 meter). Tie

wraps to hold the coils are recommended.

5. Lower the weight and float end into the tank. Two

people are needed; one to hold the assembled

section of the probe and guide the probe into the

tank, and the other to keep the coils parallel and

unwrap them. Start with tie wrap #1.

6. After the float and weight are in the tank, thread

bushing into tank or bolt flange into position.

7. If a threaded compression fitting is used, hand

tighten it. Insure compression fitting is sealed. Turn

the fitting 1 ¼ turns after hand tightening. Do not

over tighten.

8. Make a final check to see that all of the bolts and

screws are in proper position and probe is securely

tightened.