0 troubleshooting, 0 troubleshooting table, 1 fault indications on the measuring amplifier – ARI Armaturen CONA control EN User Manual

Page 33: 1 fault indications on the measuring amplifier -33, Operating and installation instructions cona, Control

Rev. 0040807014 1614

Page 2-33

Operating and Installation Instructions

CONA

®

-control

8.0 Troubleshooting

In the event of a malfunction or faulty operating performance, check that all installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

If you cannot correct the fault with the help of the table in section "9.0 Troubleshooting

table", please consult the supplier or manufacturer.

9.0 Troubleshooting table

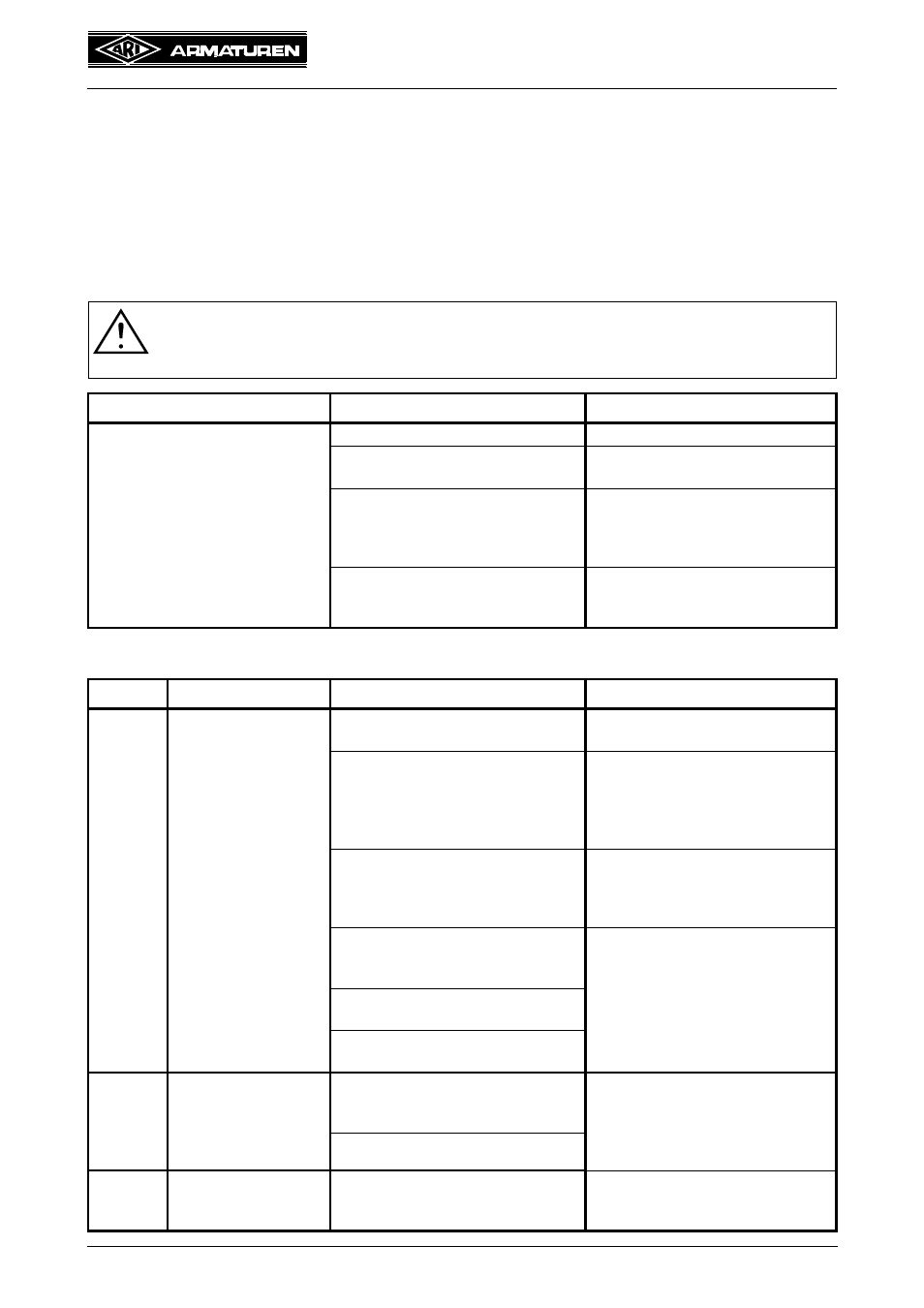

9.1 Fault indications on the measuring amplifier

ATTENTION !

- Read sections 10.0 and 11.0 prior to all dismantling or repair work!

- Read section 6.0 before restarting the plant!

Fault

Possible cause

Corrective measure

power LED not lit

Mains voltage failure

Check the mains power supply

Operating voltage is incorrect

Connect the operating voltage

indicated on the rating plate

Electronics have burnt out

Make sure the mains voltage

coincides with the value indicated

on the rating plate.

Replace the electronics

Terminal not connected correctly or

cable does not make proper contact

inside terminal

Insert the terminal securely and

check the connecting cable

Indication Meaning

Possible cause

Corrective measure

Blockage

Sensor surrounded by

cold condensate and /

or condensate

temperature is below

specified value

Detection temperature is too high

Set a lower detection temperature

(refer to 4.4 Measuring amplifier)

Depending on the steam trap type /

plant operating conditions,

condensate may collect in the test

chamber after the plant has been

shut down

No fault

The plant / part of the plant is not in

operation

High accumulation of condensate,

with the result that the capacity of

the steam trap is no longer

adequate

Select a steam trip with a higher

capacity

If thermal steam traps are installed,

the sub-cooling temperature is too

high

Refer to the Operating Instructions

for the steam trap

Blocked strainer or valve inside the

steam trap

Defective controller inside the

steam trap

Leakage

Steam leakage

Sensor surrounded by

steam and

temperature is above

specified value

Dirt has got inside the steam trap

control element, with the result that

the valve no longer closes

Check the steam trap

Refer to the Operating Instructions

for the steam trap

Controller defective

Blockage

+

Leakage

Sensor surrounded by

cold air / steam

Plant / steam trap not in operation

No fault

The plant / part of the plant is not in

operation