3 bolt-on test chamber, 4 connecting and laying the as-interface circuit – ARI Armaturen CONA control EN User Manual

Page 15

Rev. 0040807014 1614

Page 2-15

Operating and Installation Instructions

CONA

®

-control

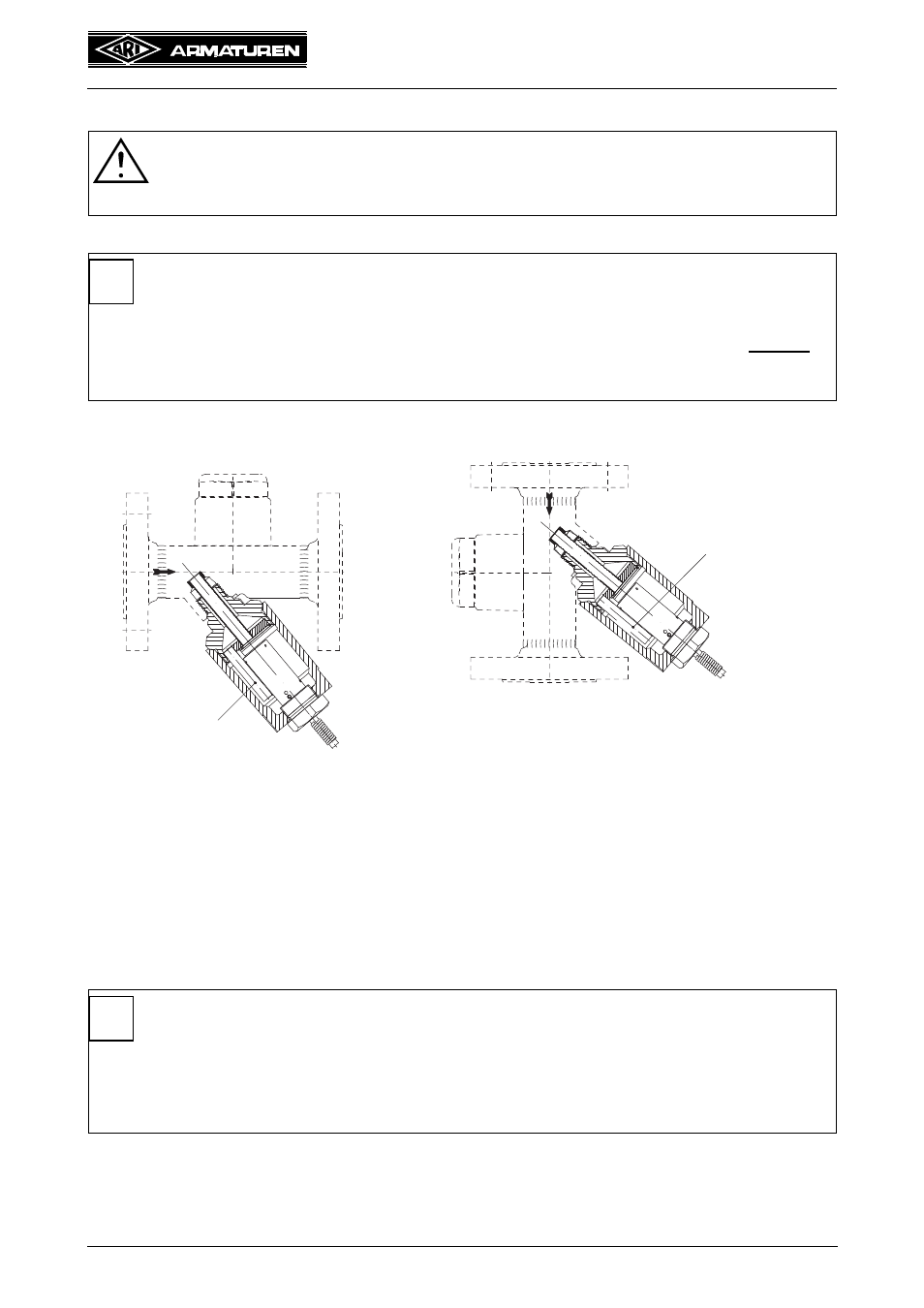

5.3 Bolt-on test chamber

Fig. 10

By unscrewing the sensor, the installation position can be inspected and if necessary

corrected. The outlet pipes are just fixed by a circlip and can be turned simply to the right

position.

5.4 Connecting and laying the AS-Interface circuit

In principle, flat and round cables can be combined. The prevailing external conditions

determine whether the cables should be made of rubber (max. 85°C), TPE (max. 105°C),

PVC (max. 90°C) or PUR (max. 85°C).

Please heed the following points when laying the AS-Interface:

- Always use the yellow, shaped AS-Interface if possible (brown for "+" and blue for "-").

ATTENTION !

- Make sure the inlet and outlet are shut off prior to all work on the steam trap.

The device must be de-pressurised and cooled down!

NOTE !

Note the installation position!

- Test chamber pointing diagonally downwards.

- For correct function of the bolt-on test chamber, the outlet pipes must always

be at the lowest point of the body.

Otherwise steam flow can not be detected.

Vertical installation

Horizontal installation

NOTE !

- Use a special AS-Interface cable with reverse polarity protection.

- Max. cable length: 100 m.

- If 100 m is too short, several manufacturers such as Bihl&Wiedemann or

Pepperl&Fuchs today offer solutions up to 1000 m, for example using

repeaters, passive bus terminating resistors or tuners.

i

Outlet pipe

Outlet pipe

i