Calibration direction, Analog output full scale value – Red Lion IFMA User Manual

Page 7

7

5.1 Place DIP switch 4 to the ON (up) position and DIP switches 5, 6, and 7 as shown.

5.2 The Green input LED blinks the corresponding Maximum Response Time Setting (see

following list), pauses and repeats.

If the existing Maximum Response Time setting is your desired requirement, this section is

complete

*

. Otherwise, continue with Step 5.3.

5.3 Press the push-button. The Green input LED blinks rapidly. Maximum Response Time setting

is now accessed.

5.4 Turn the rotary switch to the selected numerical value for Maximum Response Time desired.

(see list in Step 5.2)

5.5 Press the push-button. The Green input LED blinks the value entered, pauses, and repeats the

new Maximum Response Time setting.

If the new Maximum Response Time setting is acceptable, this section is complete

*

.

If the new Maximum Response Time setting is not acceptable, repeat from Step 5.3.

If the Red output LED blinks, the rotary switch numerical value is invalid. Repeat Steps 5.4

and 5.5.

*

Section complete; place DIP switch 4 to the Down position for normal operation, or change DIP

switches 5, 6, and 7 for the next Configuration Section.

6.0 Calibration

Analog Output Minimum Value

5.0 Maximum Response Time Setting (Low Frequency Cut-Out Setting)

5

4

7

6

The IFMA is factory calibrated for all operating modes. These settings are

permanently stored in the unit’s configuration memory. The IFMA automatically

selects the proper calibration setting for the selected Operation mode.

The Minimum and Full Scale output values established at the factory can be

changed using the calibration routines. The Minimum output value can be

adjusted to any value less than the Full Scale output value, and the Full Scale

value can be adjusted to any value greater than the Minimum value.

Changing the factory calibration settings does affect the accuracy of the unit.

Specified accuracy for modes 2, 3, and 4 holds until the factory calibration

range has been halved. This does not apply to mode 1, since it already uses only

half of the IFMA’s output range. When increasing the output range, the new

calibration settings can not exceed the factory Full Scale value by more than

10%. The 0 to 5 VDC range can be doubled.

The IFMA can store user calibration settings for only one mode at a time. If

calibration is changed for one operating mode, and the user then selects a

different operating mode, the unit reverts to factory calibration settings.

Calibration steps can be combined (added) to obtain a total calibration change.

This is done by repeated push-button entries of the same value, or different

values, before saving the change. The calibration steps as shown in the table at

right are approximations. A current or volt meter should be connected to the

appropriate output pins to verify the actual calibration setting.

Approximate Calibration Increments

ROTARY

SWITCH

VOLTAGE

CURRENT

1

3

mV

5

μA

2

5

mV

10

μA

3

10

mV

25

μA

4

25

mV

50

μA

5

50

mV

100

μA

6

100

mV

200

μA

7

200

mV

400

μA

8

400

mV

800

μA

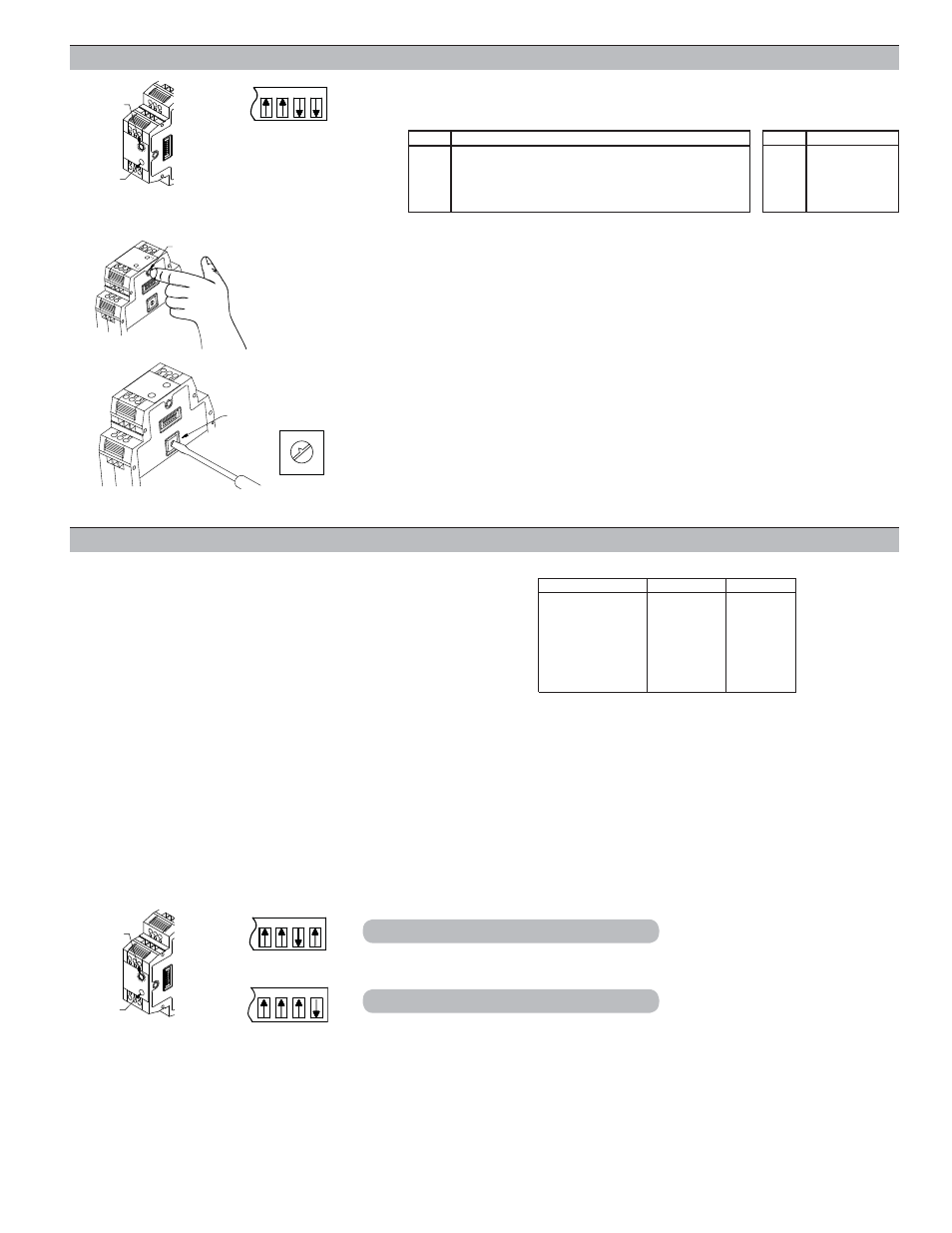

Calibration Direction

The default direction for calibration changes is up (increasing values) on

entry to either calibration routine. This direction can be toggled from within the

routine with the following steps:

1. Enter the calibration routine you wish to change (Minimum or Full Scale).

2. Press the push-button. The Green input LED blinks rapidly.

3. Turn the rotary switch to position 9. Press the push-button.

4. The Output LED indicates the direction of calibration:

OFF = Increasing Value

ON = Decreasing Value

Analog Output Full Scale Value

0

9

8

7 6 5 4

3

2

1

Step 5.2

Step 5.1

6.1 Connect a current or voltmeter of appropriate accuracy to the desired output pins (voltage or

current)

6.2 Place DIP switch 4 to the ON position and DIP switches 5, 6, and 7 as shown. The Green input

LED blinks slowly.

5

4

7

6

Step 6.2

5

4

7

6

Step 6.2

Step 6.2

Setting ‘9’

Selected

Setting Time

0

1

10 msec (100 Hz)

2

20 msec (50 Hz)

3

50 msec (20 Hz)

4

100 msec (10 Hz)

1024 times Input Range period (40 msec min., 10 sec max.)

Setting Time

5

200 msec (5 Hz)

6

500 msec (2 Hz)

7

1 sec (1 Hz)

8

5 sec (.2 Hz)

9

10 sec (.1 Hz)

LED

LED

OUTPUT

RED

GREEN

INPUT

BLINKS

OFF

IN

OUT

LED

LED

OUTPUT

RED

GREEN

INPUT

BLINKS

OFF

IN

OUT

PUSH-BUTTON

OUT

IN

STATUS

Step 5.3

OUT

IN

ROTARY

SWITCH

Step 5.4