Specifications (cont’d), Overview, Block diagram – Red Lion IFMA User Manual

Page 2

2

10

12

AC VERSION

ISOLATED

OUTPUT

SUPPLY

SUPPLY

PROCESS

INPUT

INPUT

PROCESS

SUPPLY

SUPPLY

OUTPUT

ISOLATED

DC VERSION

12

10

INPUT

(GREEN)

OUTPUT

(RED)

+5V

INPUT LED

OUTPUT LED

S4

S5

S6

S7

MODE

CFG2

CFG1

CFG0

BCD

SWITCH

BCD

INPUTS

PUSH

BUTTON

BUTTON

INPUT

DIP

SWITCH

INPUTS

PROCESS

CIRCUITRY

8

7

9

S3

SINK

3.9K

1K

S1

SRC

+

-

10.0K

0.1µf

100pf

33.2K

8.06K

54.9K

392K

10K

S2

LOGIC

+12V

+5V

+5V

+12V

+12V

INPUT

SIGNAL

9 to 32 VDC

+5V

+5V

+5V

200K

0.1µf

-

+

47.5K

+

-

3

4

1

6

10.0K

200K

10.0K

24.3Ω

1.47K

O

V+

I+

I-

V-

Vref

Vout

OUTPUT

DAC

ISOLATED ANALOG OUTPUT

0.1µf

18Vo

SUPPLY

12 VDC

SIGNAL

INPUT

COMMON

OUTPUT

DAC

CONTROL

LINES

SENSOR

INPUT

PUSH

DC

SWITCHING

CIRCUIT

(60 mA)

(AC VERSION ONLY)

+

-

85 to 250

VAC

AC

POWER

AC

SWITCHING

CIRCUIT

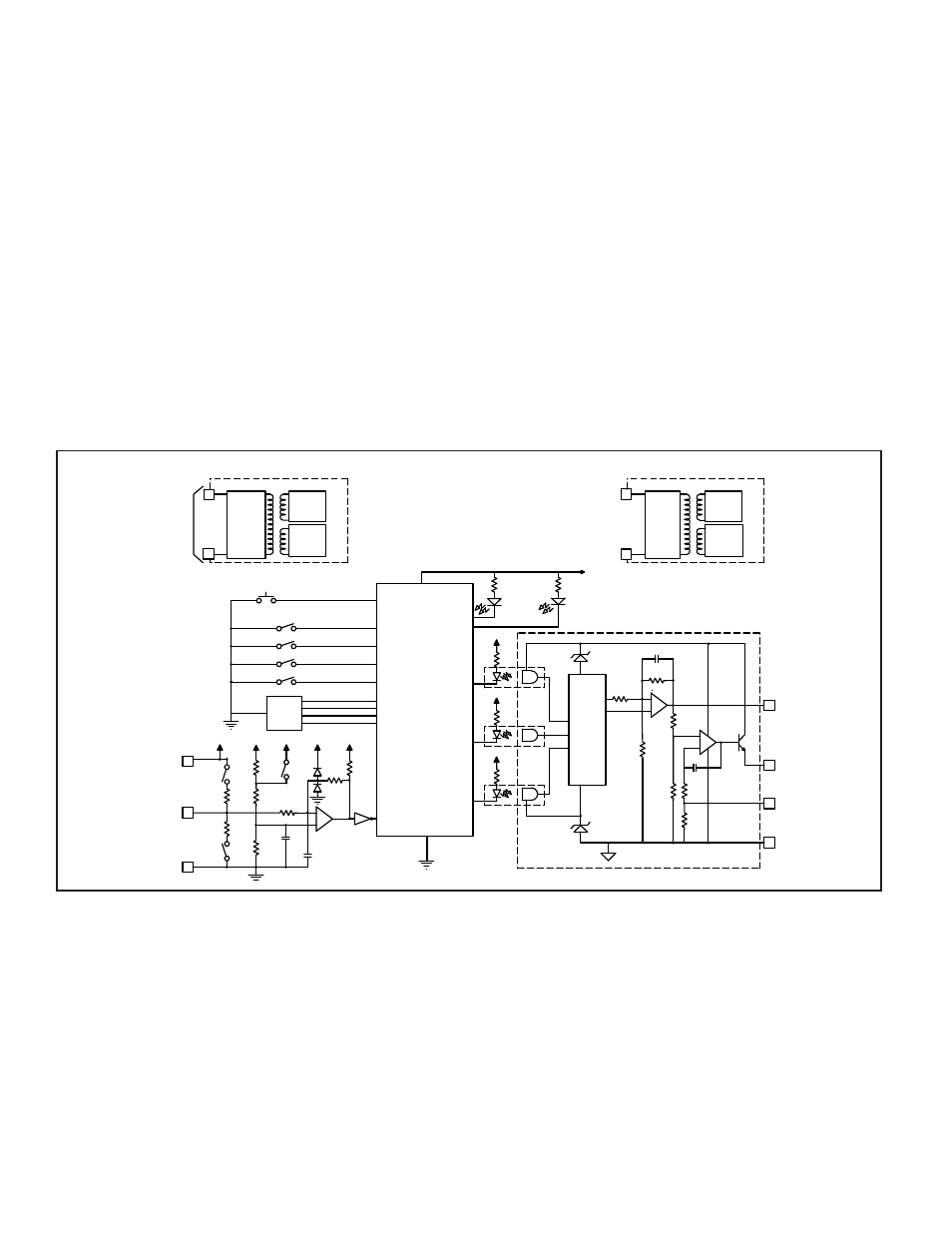

BLOCK DIAGRAM

SPECIFICATIONS (Cont’d)

10. RESPONSE TIME: 5 msec +1 period to 10 sec +1 period; user selectable

11. INPUT IMPEDANCE: 33 K

min. with the sink and source DIP switches

in the OFF position (See Block Diagram).

12. INPUT AND POWER CONNECTIONS: Screw in terminal blocks.

13. ISOLATION BREAKDOWN VOLTAGE (Dielectric Withstand): 2200

V between power & input, and power & output; 500 V between input &

output for 1 minute.

14. CERTIFICATIONS AND COMPLIANCES:

SAFETY

UL Recognized Component, File #E137808, UL508, CSA C22.2 No. 14

Recognized to U.S. and Canadian requirements under the Component

Recognition Program of Underwriters Laboratories, Inc.

IECEE CB Scheme Test Report # 97ME50135-042297

Issued by Underwriters Laboratories, Inc.

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment

for measurement, control, and laboratory use, Part 1.

EMC EMISSIONS:

Meets EN 50081-2: Industrial Environment.

CISPR 11 Radiated and conducted emissions

EMC IMMUNITY:

Meets EN 50082-2: Industrial Environment.

ENV 50140 - Radio-frequency radiated electromagnetic field

1

ENV 50141 - Radio-frequency conducted electromagnetic field

EN 61000-4-2 - Electrostatic discharge (ESD)

2

EN 61000-4-4 - Electrical fast transient/burst (EFT)

EN 61000-4-8 - Power frequency magnetic field

Notes:

1. For operation without loss of performance:

Unit is mounted on a rail in a metal enclosure (Buckeye SM7013-0 or

equivalent) and I/O cables are routed in metal conduit connected to

earth ground.

2. This device was designed for installation in an enclosure. To avoid

electrostatic discharge, precautions should be taken when the device is

mounted outside an enclosure. When working in an enclosure (ex. making

adjustments, setting switches, etc.) typical anti-static precautions should

be observed before touching the unit.

Refer to the EMC Installation Guidelines section of this bulletin for

additional information.

15. ENVIRONMENTAL CONDITIONS:

Operating Temperature: 0 to 50°C

Storage Temperature: -40 to 80°C

Operating and Storage Humidity: 85% max. (non-condensing) from 0°C

to 50°C.

Vibration according to IEC 68-2-6: Operational 5 to 150 Hz, in X, Y, Z

direction for 1.5 hours, 3 g’s.

Shock according to IEC 68-2-27: Operational 30 g’s, 11 msec in 3 directions.

Altitude: Up to 2000 meters

16. CONSTRUCTION: Case body is black, high impact plastic. Installation

Category II, Pollution Degree 2

17. WEIGHT: 6 oz. (0.17 Kg)

OVERVIEW

The Model IFMA continuously monitors a frequency input and outputs a

voltage or current signal in proportion to the input signal. The output is accurate

to ±0.1% of full scale for Operating Modes 2, 3, and 4. Operating Mode 1 is

accurate to ±0.2% of full scale. The green Input LED blinks at the rate of the

input frequency. At about 100 Hz, the Input LED will appear to be solid on. At

very low frequencies, the Input LED blinks slowly and may also appear to be

solid on. A loss of signal may also cause the Input LED to remain on, depending

on the DIP switch set-up. In this case, the red LED also turns on.

The Minimum Response Time parameter sets the minimum update time of the

output. The actual response time is the Minimum Response Time plus up to one

full period of the input signal. The IFMA counts the negative edges occurring

during the update time period, and computes the average frequency value for that

time. This action filters out any high frequency jitter that may be present in the

input signal. The longer the Minimum Response Time, the more filtering occurs.

The Maximum Response Time parameter sets the Low Frequency Cut-out

response time for the unit. If a new edge is not detected within the time specified

by the Maximum Response Time setting, the unit sets the output to the

existing Low Frequency Cut-out Value setting depending on the selected range

and calibration setting.

The unit also indicates Low Frequency Cut-out by turning ON the output

LED. The Maximum Response Time can be set shorter than the Minimum

Response Time. In this case, as long as the input signal period is shorter than the

Maximum Response Time, the unit continues to indicate the input frequency at

its output. But, if the input period at any time exceeds the Maximum Response

Time, the unit immediately takes the output to the Low Frequency Cut-out

Value, regardless of the Minimum Response Time setting.

The IFMA is calibrated at the factory for all of the selected ranges. However,

the user can adjust the minimum calibration to any value less than the Full Scale

value, and the Full Scale value to any value greater than the minimum value. If

the minimum and full scale values are brought closer together, the accuracy of the

unit decreases proportionate to the decreased range of the unit (See Calibration).