Application, Time – Red Lion PSC User Manual

Page 6

6

APPLICATION

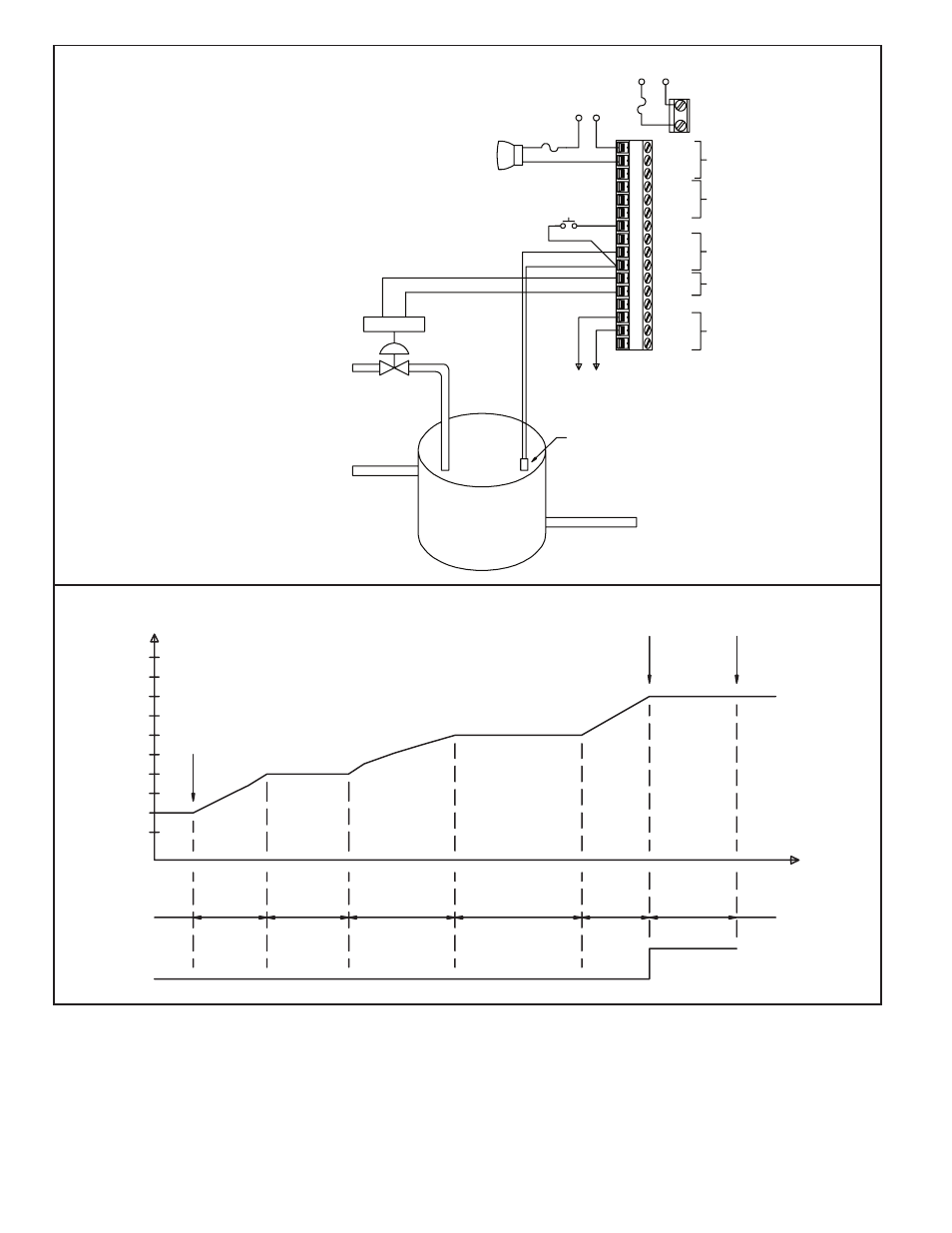

A chemical treatment process requires the PH level of a solution be ramped

at staged levels over specific time periods during start-up. The PSC unit is

installed to meet this requirement.

After the tank is filled, the PSC’s user input is triggered to run profile 1 to

start the process. Alarm output 2 signals the operator if the PH level deviates

outside the running profile. The error band (profile conformance) is

programmed to the desired value to prevent the PH level from deviating from

the programmed setpoint profile. Timed event output 1 signals that the

profile process is complete.

11

10

9

8

7

6

5

4

3

2

pH

PROFILE

STARTED

PROFILE

PHASE

EVENT

OUTPUT 1

P1r1

P1 1

P1H1

P1 2

P1r2

P1 3

P1 4

P1 5

P1H2

P1r3

P1H3

LAST

PROFILE

PHASE

PROFILE

COMPLETE

TIME

P1 7

ON

115 VAC

(MAIN POWER)

4-20mA ANALOG OUTPUT OPTION

(RETRANSMIT % OUTPUT POWER)

MAIN CONTROL OUTPUT

DC INPUTS

ALARM 1 OPTION

(RELAY MODULE INSTALLED)

ALARM 2 OPTION

(RELAY MODULE INSTALLED)

115 VAC

PH DEVIATION

ALARM

HORN

CHEMICAL

TO BE

ADDED

I/P CONVERTER

TO END OF

PROCESS

INDICATOR

PH SENSOR

OUT

IN

1

AL2/OP2--A

2

AL2/OP2--B

3

AL2/OP2--C

4

OP1--A

5

OP1--B

6

OP1--C

7

USER INPUT

8

0--10V

9

4--20mA

10

COMM.

11

OUT+

12

OUT--

13

N/C

14

AL1--A

15

AL1--B

16

AL1--C