Output modules, Application – Red Lion PCU User Manual

Page 7

7

PROTECTED PARAMETERS MODE

*

The protected parameters mode is enabled when program disable is active.

This mode prevents access to the configuration modes without the proper access

code number. Only the parameters that are selected in the configuration 3

parameter lock-out section can be accessed.

“ProP”

- Enter Proportional band

“Intt”

- Enter integral time

“dErt”

- Enter derivative time

“rtio”

- Enter remote setpoint ratio value

“bIAS”

- Enter remote setpoint bias value

“SP-2”

- Enter internal cascade, secondary setpoint

“Pb-2”

- Enter internal cascade, secondary

proportional band

“It-2”

- Enter internal cascade, secondary integral

time

“dt-2”

- Enter internal cascade, secondary derivative

time

“AL-1”

- Enter value for alarm #1

“AL-2”

- Enter value for alarm #2

“CodE”

- Enter access value to unprotected

parameters & configuration parameters

*

These parameters may not appear due to option configuration or other

programming.

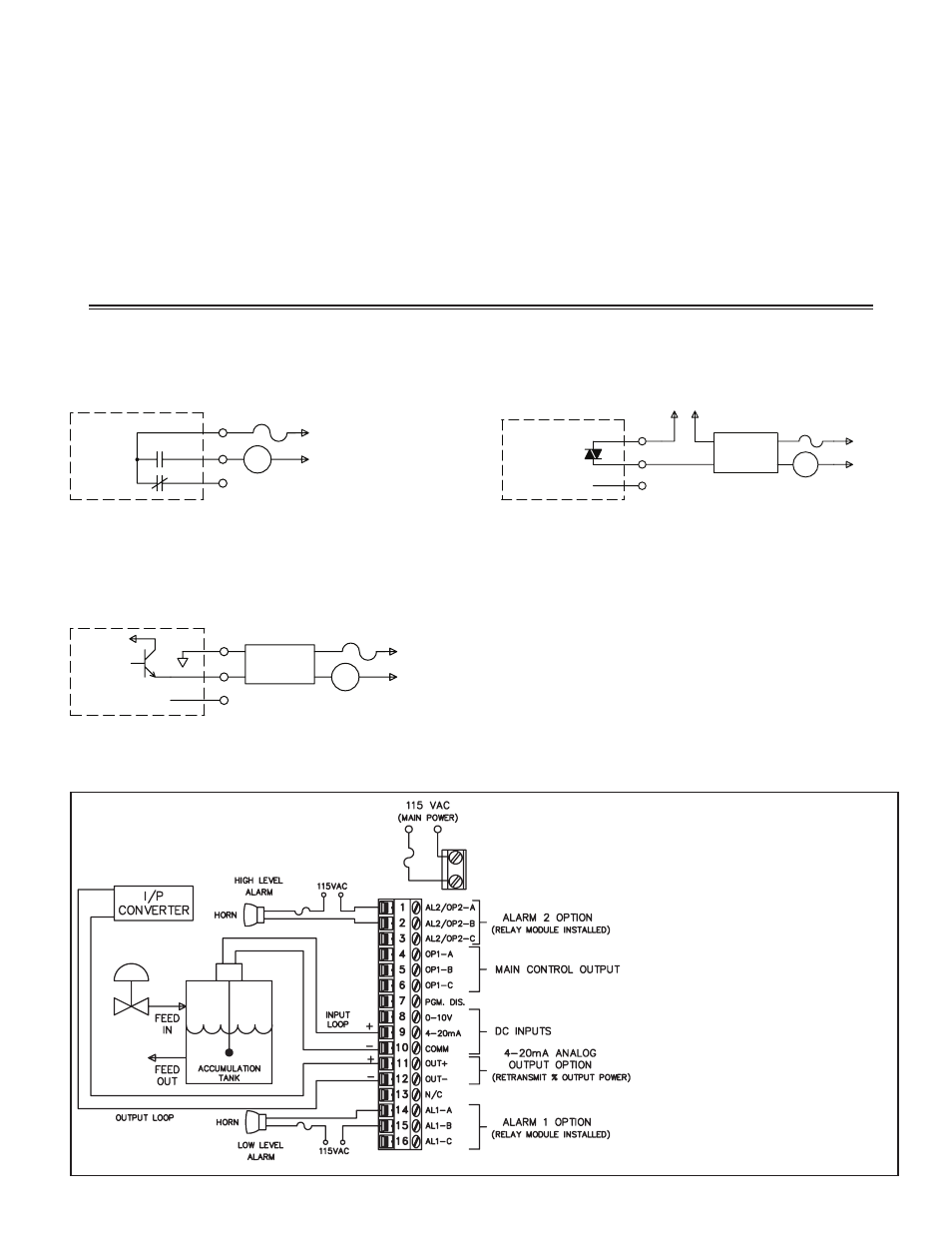

OUTPUT MODULES

TYPICAL CONNECTIONS

Relay:

Type: Form-C (Form-A with some models. See ordering information.)

Rating: 5 amps @ 120/240 VAC or 28 VDC (resistive load), 1/8 HP @ 120

VAC (inductive) maximum.

Life Expectancy: 100,000 cycles at maximum load rating.

(Decreasing load and/or increasing cycle time, increases life expectancy).

Logic/SSR Drive: Can drive multiple SSR Power Units.

Type: Non-isolated switched DC, 12 VDC typical

Drive: 45 mA maximum.

Triac:

Type: Isolated, Zero Crossing Detection

Rating:

Voltage: 120/240 VAC

Max. Load Current: 1 ampere @ 35°C

0.75 ampere @ 50°C

Min. Load Current: 10 mA

Off State Leakage Current: 7 mA max. @ 60 Hz

Operating Frequency: 20 to 400 Hz

Protection: Internal Transient Snubber, Fused

LOAD

A

B

C

POWER

5 AMPS

AT

240

VAC

RELAY

MODULE

DO NOT CONNECT

SSR

POWER

UNIT

LOAD

4

3

1

2

A

B

C

POWER

+12VDC

UNREG.

+

-

NOT

ISOLATED

LOGIC/SSR DRIVE

MODULE

POWER

120VAC

AT

1 AMP

120/240VAC

ISOLATED

A

B

C

RELAY OR

DEVICE

TRIAC

LOAD

DO NOT CONNECT

TRIAC MODULE

APPLICATION

A chemical company would like to

maintain the level of an acid solution tank to

insure constant availability for their process.

They have chosen a PCU controller which

has a continuous level probe with a 4 to 20

mA output proportional to tank level,

connected to the input terminals. The tank is

filled by controlling the position of a

proportional control valve. The control valve

is controlled by a 3 to 15 PSI air signal.

The PCU uses the level control input as its

feedback. The 4 to 20 mA input signal is

scaled so that 4 mA equals 0% and 20 mA

equals 100%.

The 4 to 20 mA output of the PCU is taken

to an I/P converter to convert the 4 to 20 mA

output to a 3 to 15 PSI signal for the control

valve. The relay outputs of the PCU are used

for high and low level alarms.