Hardware features, Setpoint features, Input features – Red Lion PCU User Manual

Page 4: Output features, Auto-tune, Options, Ratio control, Motorized valve positioner

4

HARDWARE FEATURES

The fast 100 msec input sampling rate provides quick controller response to

a process disturbance, thus providing excellent process control. Measurement

accuracy of 0.15% or better, provides closer process control conforming to the

desired control setpoint value. The unit accepts either a 0 to 10 VDC or a 0 to

20 mA DC input signal. The AC input power is switch selectable, allowing the

unit to operate from either 115 VAC or 230 VAC. Since the controller is

serviceable from the front of the panel, the output modules may be easily

changed or replaced without disturbing the wiring behind the panel. No

re-programming is required when changing or replacing modules.

The optional Type 4X/IP65 rated model utilizes two bezel securing screws

and a neoprene gasket to guarantee a water tight seal, when properly installed.

The standard model simply requires pressing a latch to remove the unit.

Low-drift, highly stable circuitry ensures years of reliable and accurate

process control. The recommended two-year re-calibration interval is easily

accomplished via the programming menu.

SETPOINT FEATURES

The controller setpoint can be protected from out of range values by

programming the setpoint range limit values. Additionally, safeguards from

inadvertent data entry can be programmed.

The setpoint ramp feature ramps the setpoint value at start-up or any time a

setpoint change is made, at a user programmable rate. This feature reduces

shock to the process and helps to minimize overshoot. The setpoint may also be

transmitted by the optional linear DC output for slave control loops.

The second analog input may be configured as a remote setpoint. As such, the

controller is easily switched from local/remote setpoint operation via the front

panel or user input. Ratio and bias parameters provide on-line scaling of the

remote setpoint. Absolute limit values and maximum rate of change of the

remote setpoint further enhance controller flexibility.

INPUT FEATURES

A programmable input filter can be used to stabilize readings from a process

with varying or oscillating characteristics, helping to provide better process

control. Programmable scaling points allow the controller to display in any

engineering unit; flow, level, pressure, etc. Scaling points are used in

conjunction with the programmable rounding increment to stabilize a jittery or

otherwise hard to read process signal for better indication.

The programmable User Input can be used to control a variety of functions,

such as auto/manual transfer of the controller, reset alarm output(s), etc.

The second analog input has independent scaling parameters to match the

units of other processes or transmitters, or to match the controller’s range.

OUTPUT FEATURES

Programmable output power limits provide protection for processes where

excessive power can cause damage. Automatic signal overdrive detection, for

fail-safe operation, causes the controller to default to a programmed output

power (upscale or downscale burnout). With adjustable time proportioning

cycle time, and programmable DC linear output, the controller can satisfy a

wide variety of output requirements.

Programmable dampening output hysteresis and output update time parameters

can dramatically reduce actuator activity without degrading control accuracy.

The RS485 Communication option allows the user to access various

controller parameters such as the setpoint, % output power, % proportional

band, etc. The controller may be set up to transmit various parameters at a

programmable automatic print rate.

AUTO-TUNE

The PCU has an auto-tune feature that, on demand, automatically determines

the PID control parameters for a particular process. After completion of auto-

tune, the PID parameters are automatically optimized for that process and

loaded into nonvolatile memory. The operator may view and modify the

parameters as desired.

Auto-tune may be invoked either at start-up or at setpoint, depending on the

process requirements. An auto-tune programmable dampening factor produces

various levels of process control and response characteristics.

OPTIONS

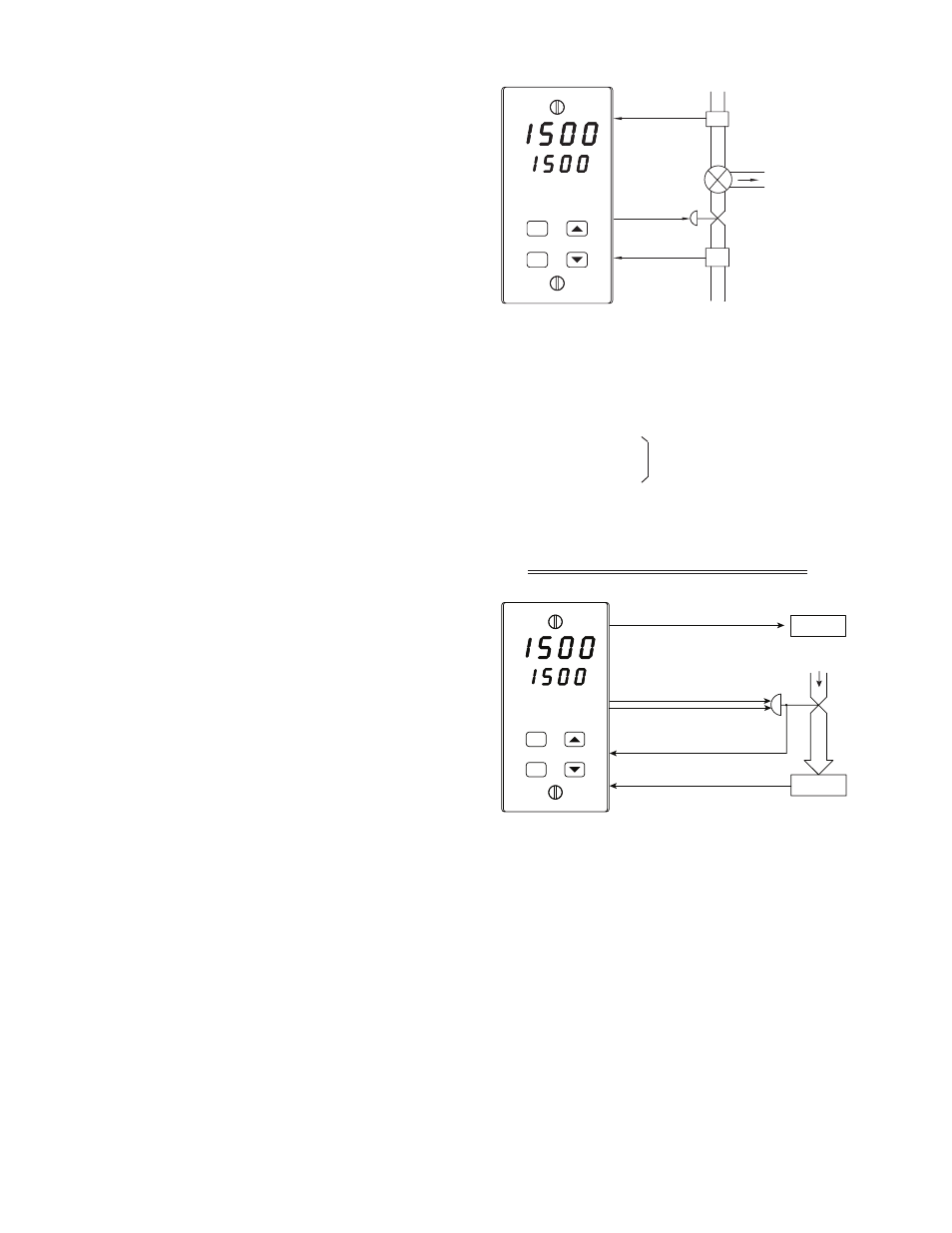

RATIO CONTROL

The PCU configured for ratio operation controls a process as a ratio of

another process or to another variable. Ratio control is commonly used for flow

applications, however, any two process variables can be controlled in a

ratio mode.

Ratio Control Configuration Parameters

“OPEr”

- Select ratio mode

“root”

- Select second input square root linearization

“dPt2”

- Select second input decimal point

“dSP1”

“INP1”

“dSP2” - Enter scaling units of second input

“INP2”

“SPtr”

- Local/Remote Select options

“InPt”

- Program User Input for Local/Remote

Setpoint selection

Ratio Control Operational Parameters

“rtio”

- Remote setpoint ratio

“bIAS”

- Remote setpoint bias

MOTORIZED VALVE POSITIONER

The motorized valve positioner controls the position of a valve directly, by

use of “open” and “close” control outputs. The slidewire feedback signals of

the valve may optionally be connected to the controller. Alternatively, the

controller may be configured for linear input valve control using the 4 to 20 mA

DC output.

Motorized Valve Positioner Configuration Parameters

Position mode: “VPS1”

- Enter or measure valve closed position

“VPS2”

- Enter or measure valve open position

“VUdt”

- Enter Valve update time

“VPdb”

- Enter valve control deadband

“VFAL”

- Enter valve fail detect time

“Act1”

- Program alarm as valve fail output

Velocity mode: “VUdt”

- Enter Valve update time

“VOPt”

- Enter valve open time

“VCLt”

- Enter valve close time

“VOnt”

- Enter valve control deadband

(minimum on time)

DSP

PAR

%PW

SEC

REM

OP1

AL1

AL2

SECOND INPUT

UNCONTROLLED

FLOW

LINEAR DC

OUTPUT

MAIN INPUT

CONTROLLED

FLOW

FLOW C = FLOW A + FLOW B

FLOW A

FLOW B = [RATIO * FLOW A] + BIAS

DSP

PAR

%PW

DEV

MAN

AL1

OPN

CLS

VALVE OPEN OUTPUT

VALVE CLOSE OUTPUT

SECOND INPUT

VALVE POSITION

MAIN INPUT

PROCESS

STEAM FLOW

VALVE FAIL

ALARM

AL1 OUTPUT