Wiring, Wiring connections, Cspid1 input connections – Red Lion CSPID User Manual

Page 5: Cspid2 input connections, Rtd heater current monitor voltage, Current thermocouple and millivolt

5

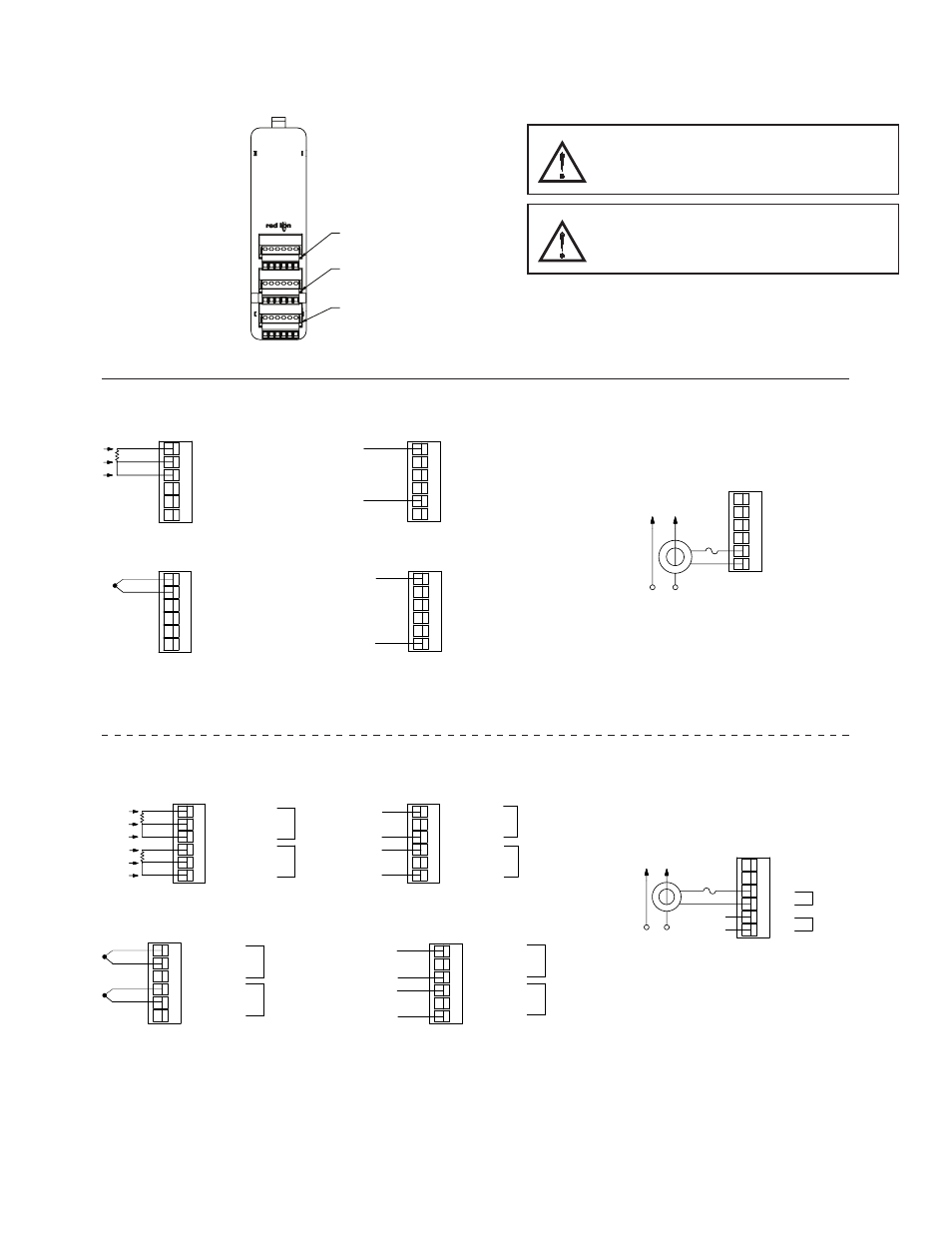

WIRING

WIRING CONNECTIONS

All conductors should meet

voltage and current ratings for

each terminal. Also, cabling

should conform to appropriate

standards of good installation,

local codes and regulations.

When wiring the module, use

the numbers on the label to

identify the position number

with the proper function. Strip

the wire, leaving approximately

1/4" (6 mm) of bare wire

exposed. Insert the wire into

the terminal, and tighten.

1

7

13

Terminals 13 to 18

Terminals 7 to 12

Terminals 1 to 6

TC/RTD+

INPUT COM.

4-20 mA

0-10 V

N/C

RTD +EXE

1

3

2

5

4

6

SENSE

SENSE

EXC./

JUMPER

6

5

4

3

2

1

0-10 V

4-20 mA

N/C

TC/RTD+

INPUT COM.

RTD +EXE

+

6

5

4

3

2

1

0-10 V

4-20 mA

N/C

TC/RTD+

INPUT COM.

RTD +EXE

mA DC-

mA DC+

6

5

4

3

2

1

0-10 V

4-20 mA

N/C

TC/RTD+

INPUT COM.

RTD +EXE

VDC-

VDC+

12

11

10

9

8

7

HCM (OPT)

HCM (OPT)

OP2 COM

OP1 COM

OP1 +

OP2 +

Heater Circuit

AC

RTD

Heater Current Monitor

Voltage

CSPID1 INPUT CONNECTIONS

Current

Thermocouple and Millivolt

TC/RTD+

INPUT COM.

PROC/RTD EXC

TC/RTD+

INPUT COM.

PROC/RTD EXC

1

3

2

5

4

6

12

EXC./JUMPER

SENSE

SENSE

SENSE

SENSE

EXC./JUMPER

INPUT COM.

+

+

PROC/RTD EXC

TC/RTD+

TC/RTD+

INPUT COM.

PROC/RTD EXC

5

6

3

4

2

1

2

1

mA DC+

mA DC+

mA DC-

mA DC-

PROC/RTD EXC

PROC/RTD EXC

TC/RTD+

TC/RTD+

INPUT COM.

INPUT COM.

6

5

4

3

2

1

2

1

6

5

4

3

2

1

TC/RTD+

PROC/RTD EXC

INPUT COM.

TC/RTD+

INPUT COM.

PROC/RTD EXC

VDC+

VDC-

VDC-

VDC+

1

2

18

17

16

15

14

13

HCM

HCM

HCM

OP4 COM

OP4 +

HCM

Heater Circuit

AC

2

1

SAME AS

HCM 1

{

RTD

Heater Current Monitor

Voltage

CSPID2 INPUT CONNECTIONS

Current

Thermocouple and Millivolt

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

WHILE CIRCUIT IS ALIVE UNLESS AREA IS KNOW TO BE

NON-HAZARDOUS.

INPUT AND OUTPUT (I/O) WIRING MUST BE IN

ACCORDANCE WITH CLASS I, DIV. 2 WIRING METHODS

AND IN ACCORDANCE WITH THE AUTHORITY HAVING

JURISDICTION.