Iring, Eter, Nstalling – Red Lion LDSS User Manual

Page 2

2

5. MEMORY: Nonvolatile E

2

PROM retains all programming parameters, main

and secondary displays when power is removed.

6. CERTIFICATIONS AND COMPLIANCES:

SAFETY

UL Listed, File # E137808, UL508, CSA C22.2 No. 14-M95

LISTED by Und. Lab. Inc. to U.S. and Canadian safety standards

Type 4X Enclosure rating (Face only), UL50

IEC 61010-1, EN 61010-1: Safety requirements for electrical equipment for

measurement, control, and laboratory use, Part 1.

IP65 Enclosure rating (Face only), IEC 529

ELECTROMAGNETIC COMPATIBILITY

Emissions and Immunity to EN 61326: Electrical Equipment for Measurement,

Control and Laboratory use.

Notes:

1. Criterion A: Normal operation within specified limits.

7. CONNECTIONS:

Internal removable terminal blocks used for power and signal wiring.

Remove end plates with ¼" nut driver.

For LD2 versions power is on the right side and serial wiring is on the left

side. For LD4 versions, all wiring is on the right side of the unit.

Wire Strip Length: 0.4" (10 mm)

Wire Gage: 24-12 AWG copper wire, 90°C rated insulation only

Torque: 5.3 inch-lbs (0.6 N-m) max

Cable Diameter: Outside diameter must be 0.181" (4.6 mm) to 0.312" (7.9

mm) to maintain NEMA 4 rating of cord grips.

8. ENVIRONMENTAL CONDITIONS:

Operating temperature: 0 to 65 °C

Storage temperature: -40 to 70 °C

Operating and storage humidity: 0 to 85% max. RH (non-condensing)

Vibration According to IEC 68-2-6: Operational 5 to 150 Hz, in X, Y, Z

direction for 1.5 hours, 2 g’s (1g relay).

Shock According to IEC 68-2-27: Operational 30 g’s (10g relay), 11 msec in

3 directions.

Altitude: Up to 2,000 meters

9. CONSTRUCTION: Aluminum enclosure, and steel side panels with

textured black polyurethane paint for scratch and corrosion resistance

protection. Sealed front panel meets NEMA 4X/IP65 specifications.

Installation Category II, Pollution Degree 2.

10. WEIGHT:

LD2SS6P0: 4.5 lbs (2.04 kg)

LD4SS6P0: 10.5 lbs (4.76 kg)

2.0 W

IRING

THE

M

ETER

EMC INSTALLATION GUIDELINES

Although this meter is designed with a high degree of immunity to Electro-

Magnetic Interference (EMI), proper installation and wiring methods must be

followed to ensure compatibility in each application. The type of the electrical

noise, source or coupling method into the meter may be different for various

installations. The meter becomes more immune to EMI with fewer I/O

connections. Cable length, routing, and shield termination are very important

and can mean the difference between a successful or troublesome installation.

Listed below are some EMC guidelines for successful installation in an

industrial environment.

1. The meter should be properly connected to protective earth.

2. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield only at the panel where the unit is mounted to earth

ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

Class B

EN 55011

Emissions

Emissions:

0.5 cycle

Criterion A

3 V/rms

Voltage dip/interruptions

Criterion A

EN 61000-4-6

RF conducted interference

1 kV L-L,

Criterion A

EN 61000-4-5

Surge

1 kV signal

2 kV power

Criterion A

EN 61000-4-4

Fast transients (burst)

2 kV L&N-E power

10 V/m

Criterion A

EN 61000-4-3

Electromagnetic RF fields

8 kV air discharge

4 kV contact discharge

Criterion A

EN 61000-4-2

Electrostatic discharge

Immunity to Industrial Locations:

ORDERING INFORMATION

LD Plug

LD

LD

MODEL NO.

DESCRIPTION

PART NUMBER

LD2SS6P0

LDPLUG00

LD4SS6P0

2.25" High 6-Digit Red LED Serial Slave Display,

RS232/RS485 Serial Communications

Panel Meter Plug for LD models

4" High 6-Digit Red LED Serial Slave Display,

RS232/RS485 Serial Communications

1.0 I

NSTALLING

THE

M

ETER

INSTALLATION

The meter meets NEMA 4X/IP65 requirements when properly installed.

INSTALLATION ENVIRONMENT

The unit should be installed in a location that does not exceed the operating

temperature. Placing the unit near devices that generate excessive heat should

be avoided. The unit should only be cleaned with a soft cloth and neutral soap

product. Do NOT use solvents.

Continuous exposure to direct sunlight may accelerate the aging process of

the front overlay. Do not use tools of any kind (screwdrivers, pens, pencils, etc.)

to operate the keypad of the unit.

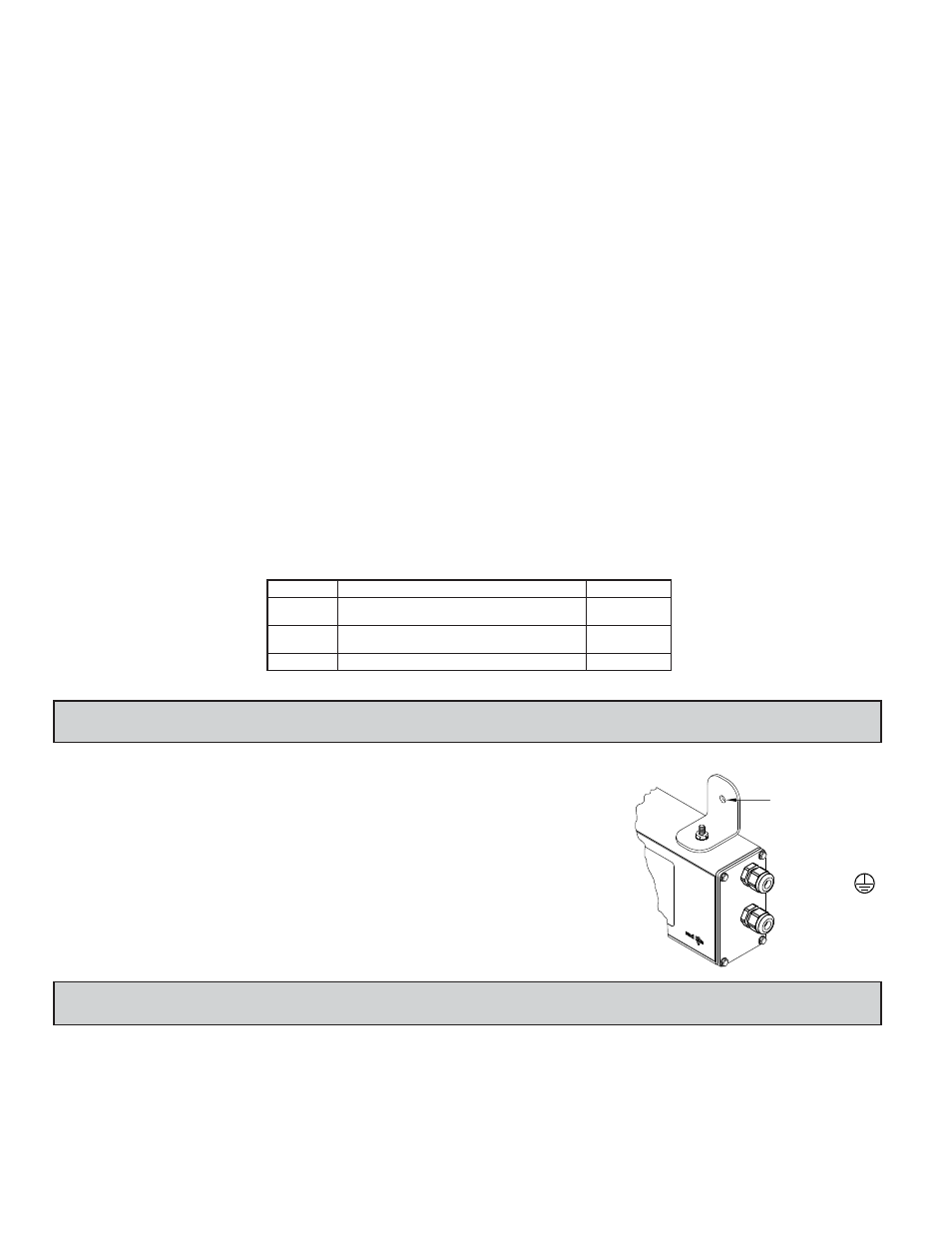

MOUNTING INSTRUCTIONS

This display is designed to be

wall mounted or suspended

from a ceiling truss or other

suitable structure capable of

supporting the LDSS.

Caution should be exercised

when hanging the display to

provide for the safety of

personnel. If hanging the

LDSS, run the suspension

cables (or chains) through the

mounting bracket holes. For wall

mounting use #10-32 size bolts.

MOUNTING HOLE (.281")

MUST BE

CONNECTED TO

TERMINAL #3 (TBA)