Posey Deluxe Drop Seat User Manual

Posey, Gss drop seat, See assembly drawing on back

Seating and PoSitioning

Quality Products since 1937

M6130 042909

A versatile solid platform drop seat that replaces existing sling seats in wheelchairs to

provide a solid foundation for cushions. Designed to fit most chairs 18” to 20” (46 cm to 51

cm) in seat width with 7/8” or 1” (2 cm or 2½ cm) seat rails. Provides seat drops of up to 3½”

(9 cm) depending on the wheelchair model. Both posterior and anterior tilt positioning can

be accommodated. 250 lb. (113 kg.) maximum weight capacity.

REF

6372 GSS Drop Seat

InstallatIon InstructIons

(reference exploded view drawing on side 2)

Tools RequiRed: Allen keys (included), AdjusTAble wRench (noT included)

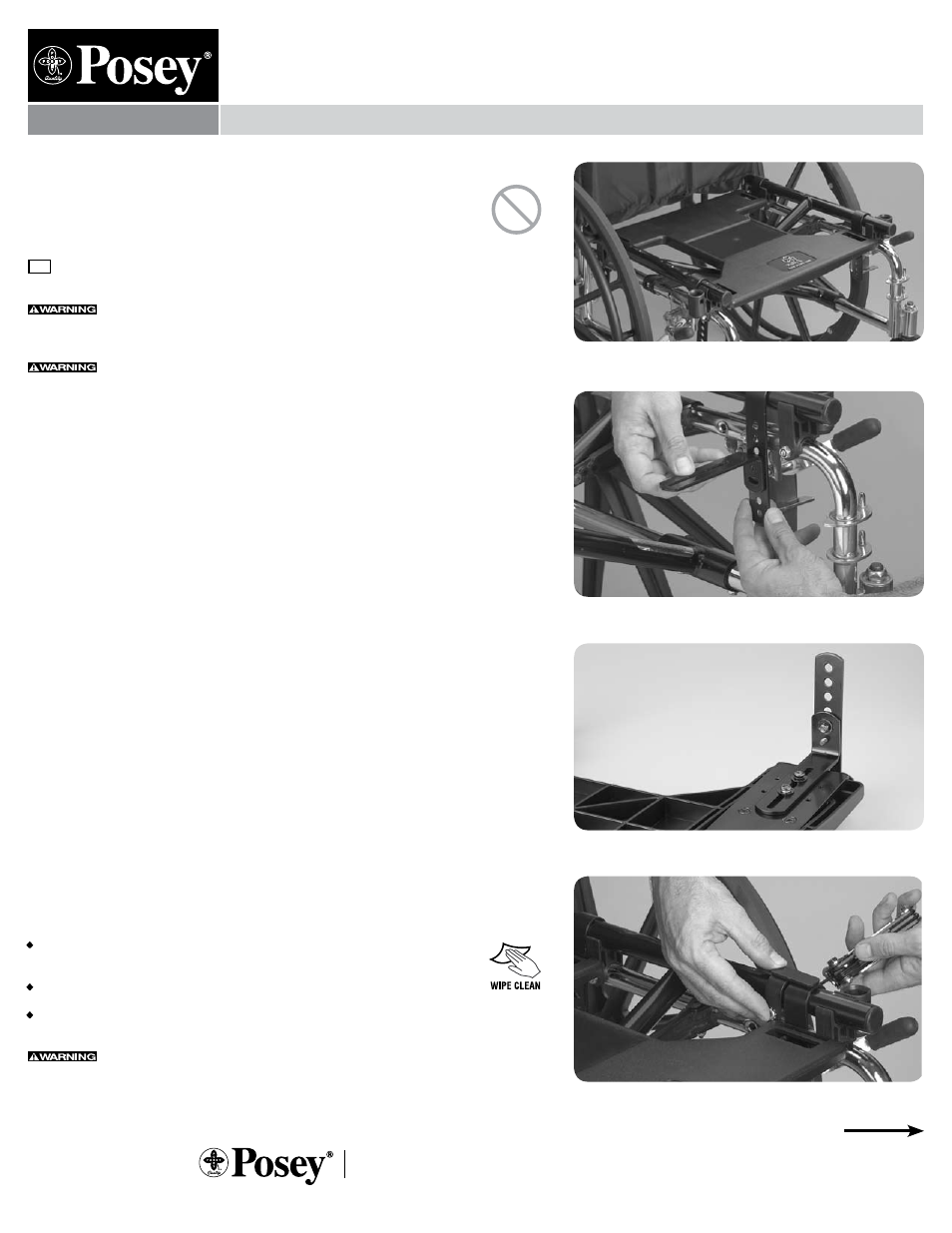

The GSS Drop Seat is shipped with two metal mounting plates mounted to the underside of

the molded seat shell. Check to see that the Flat Allen Head screws are securely tightened before

proceeding.

1. Remove existing seat upholstery from the wheelchair.

2. Determine the approximate amount of seat drop desired by hanging one of the J-brackets

(item 3) from the wheelchair seat rail and positioning one of the L-brackets (item 4) (Fig. 2).

Using hardware items 5, 6, 7 and 8, assemble the two brackets. Leave the hardware finger tight

until all the final adjustments have been made. Repeat for the remaining bracket sets.

3. On a flat surface, turn the drop seat shell upside down and position the four bracket assemblies

to the flat metal plates. Install the brackets to the middle set of mounting holes using button

head screws (item 10) and hardware (items 7 and 9) (Fig. 3). Leave the hardware finger tight

until all the adjustments have been made.

4. Turn the partially assembled drop seat right side up with the Posey logo at the front. Position

the drop seat between the cross braces of the wheelchair. Slide the metal L-brackets until the

J-brackets easily slip over the wheelchair seat rails. Check for any interference with cross braces

or any other component of the wheelchair. If any interference is noted, there are two means

of adjustments: The first is to rotate the drop seat assembly 180 degrees, as the cross brace

cutouts are located for a variety of models of wheelchairs. The second is to reposition the bracket

assemblies on the flat metal mounting plates using the alternative sets of mounting holes.

5. When the spacing of the bracket assemblies is correct, securely tighten the screws holding the

bracket assemblies to the metal flat plates.

6. Review the location of the J-brackets on the L-brackets to determine if the drop seat requirements

of the client are met, i.e. height off the ground, seat angle and that the wheelchair frame allows

it. Make any necessary changes.

7. Remove the drop seat assembly and securely tighten all the hardware using the appropriate

tools. Remount the GSS Drop Seat assembly.

8. With the drop seat on the chair, position the securing clamps on the wheelchair seat rails. They

should be located on each seat rail capturing one J-bracket to prevent the drop seat from sliding

either forward or backwards (Fig. 4). Tighten each clamp until it conforms to the tubing and is

fixed in place.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Gss Drop seat

MonItorInG

Be sure to follow your facility’s policies and guidelines for frequency of patient

monitoring.

• Wipe Clean with mild detergent. OSHA approved intermediate level disinfectants

can be used per manufacturer instructions. DO NOT use phenol and benzyl based

disinfectants.

• After cleaning, products MUST be rinsed with water to remove any residual

chemicals.

• Make sure products are completely dry before use.

DIsposal

Properly dispose of the product per facility’s policy for BIOHAZARDOUS materials.

storaGe anD HanDlInG

This device is designed for use in normal indoor environments. This device may be stored in

ambient warehouse temperatures at normal humidity levels. Avoid excess moisture or high

humidity that may damage product materials.

cleanInG InstructIons

InspectIon

Inspect before each use: check for cracked or broken plastic components; bent

metal hardware or missing items. DO NOT use soiled or damaged products. Test that the Drop

Seat will hold patient weight before patient transfer.

See Assembly Drawing on Back

Posey Company • 5635 Peck Road, Arcadia, CA 91006-0020 USA

Phone: 1.800.447.6739 • Fax: 1.800.767.3933 • Web: www.posey.com

© 2009 Posey Company. All rights reserved.

Posey

®

gSS drop Seat

LATEX