General requirements, Grounding and bonding, Sizing the electrical service – Aquacal LTM0266 User Manual

Page 28: Ground-fault protection, External controls / equipment

Page 22

“Y” and “Z”

connection

points

“FS-2”

connection

points

4.4.b General Requirements

Locate the equipment disconnect within 6-feet of the heat pump

’s electrical enclosure, or as close to

the heat pump as possible. Always satisfy applicable codes and standards.

AquaCal AutoPilot heat pumps are designed for copper conductors only. Do not use aluminum wire.

Never mount a power-disconnect directly to the heat pump.

In sizing wiring, be especially aware of up-sizing requirements necessary due to wiring distances.

Always satisfy applicable codes and standards.

Multiple heat pumps installed at the same site will benefit from special automatic sequencing

controllers to avoid excessive power drops at start-

up. An “ASC” controller is available by calling

AquaCal AutoPilot Customer Support.

See “Available Accessories” on page 35 for more

information.

4.4.c Grounding and Bonding

Follow local code requirements for properly grounding and bonding heat pump equipment.

4.4.d Sizing the Electrical Service

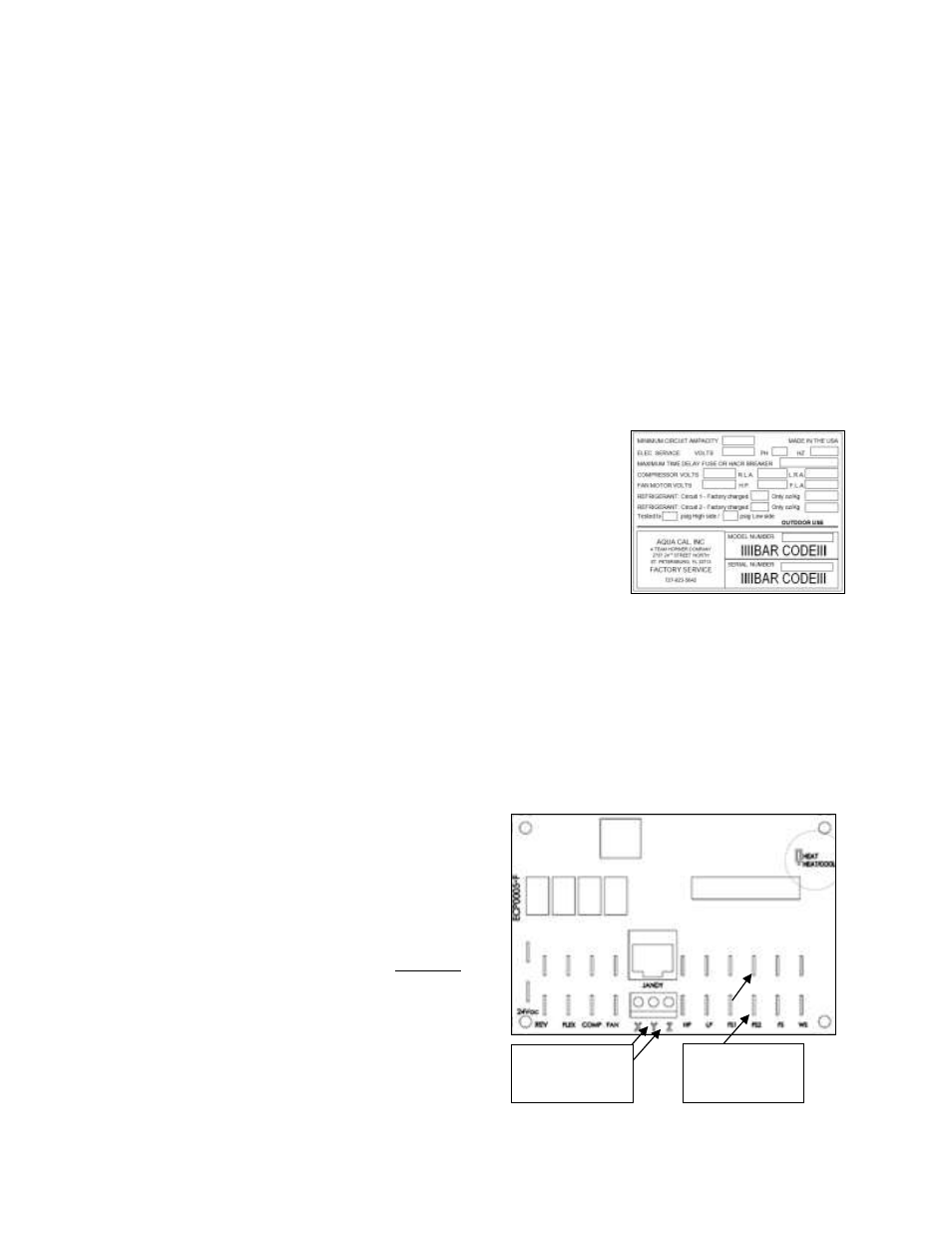

There are two (2) identical data plates on the heat pump; one located on

the outside right front corner and one behind the front access panel of

electrical enclosure.

Refer to equipment data plate (Figure 24) for specific information required

to size electrical service and over-current protection of heat pump. Sizing

is based on data plate information, wire size, wiring devices, and over-

current protection per applicable local codes and standards.

Figure 24

4.4.e Ground-Fault Protection

Local codes and regulations may require the use of a ground fault interruption device (GFI Circuit

Breaker). Nuisance tripping of these devices is common and not covered under the terms of the

M

anufacturer’s warranty.

4.4.f External Controls / Equipment

The heat pump allows external equipment to control the heat

pump’s “ON” / “OFF” functionality. A direct

connection for external controllers has been provided on the microprocessor board.

1) Connect the external controller to the terminal

block of the microprocessor board using a

minimum 18-guage low voltage wire.

2) For a two-wire controller (which has a

thermostat)

– Connect to the “Y” and “Z”

connections of the block

labeled “X-Y-Z”. See

3) For a three-wire controller (which does not

have a thermostat)

– Connect to the block

labeled “FS-2”.

4) Program the heat pump to accept an external

controller’s signal. See section entitled

“Configuring for External Controller” on page

24 for more information.

Figure 25