Monitoring conditions, Pool chemistry, Maintain proper water flow – Aquacal LTM0266 User Manual

Page 12: Adjusting water flow using ∆t (delta-t), 2 monitoring conditions

Page 6

3.2 Monitoring Conditions

3.2.a Pool Chemistry

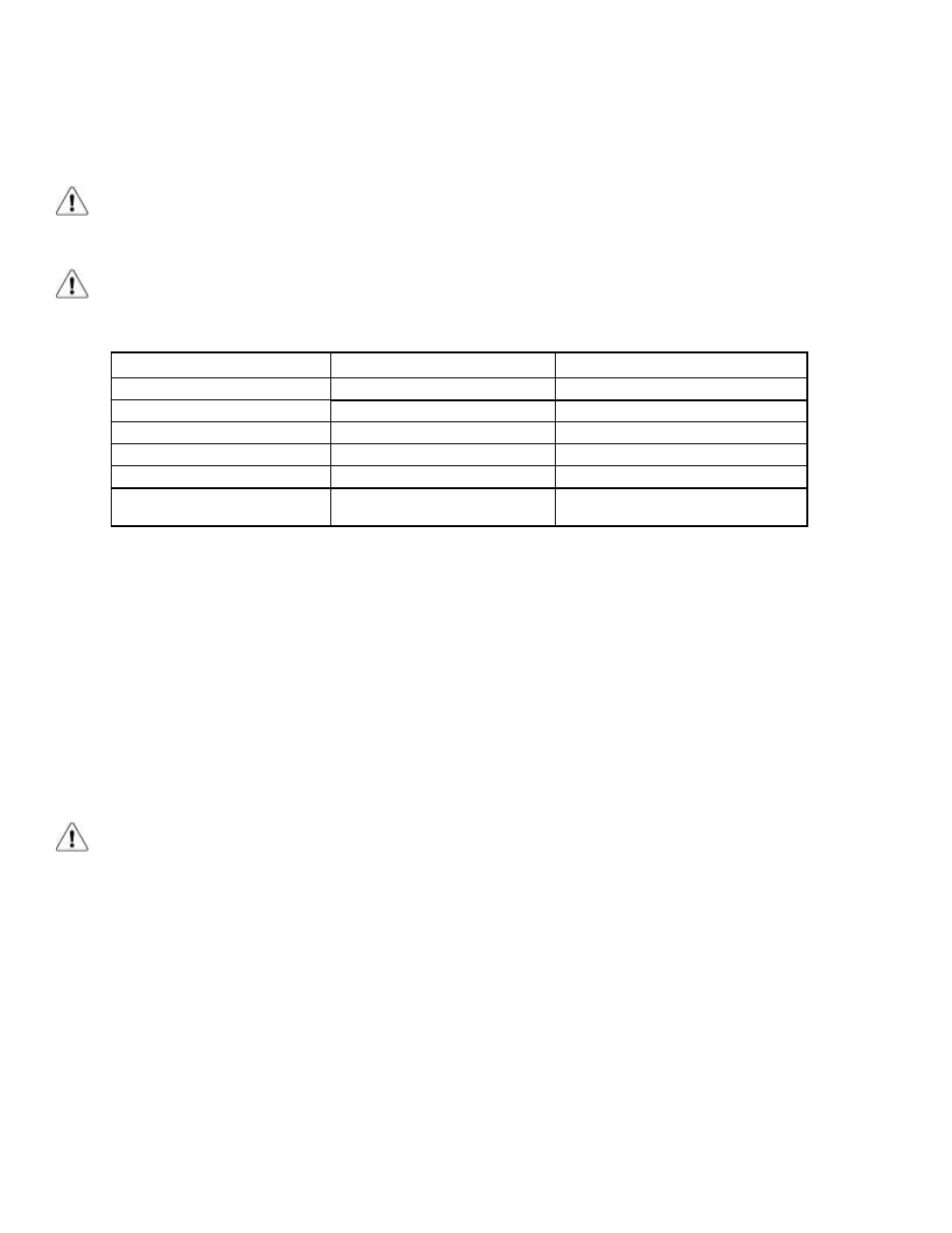

Check water chemistry regularly and maintain within recommended levels as shown in Table 6. Standards

for commercial applications vary in different areas. Follow all local applicable codes.

CAUTION

- Failure to heed the following may result in equipment damage.

Stop water flow when refinishing or acid washing pool. Failure to follow these

instructions may damage equipment and voids heat pump warranty.

CAUTION

- Failure to heed the following may result in equipment damage.

To avoid damage to equipment, monitor and maintain chemistry within

recommended levels.

CHEMICAL

POOLS

SPAS

Chlorine

1.0

– 3.0 ppm

1.5

– 3.0 ppm

Bromine

2.0

– 4.0 ppm

3.0

– 5.0 ppm

pH

7.4

– 7.6 ppm

7.2

– 7.8 ppm

Total Alkalinity

80

– 140 ppm

80

– 120 ppm

Calcium Hardness

200

– 400 ppm

200

– 400 ppm

Total Dissolved Solids

1,000

– 2,000 ppm

1,500 ppm above start-up TDS in

spas

Table 6

3.2.b Maintain Proper Water Flow

Water flow through the heat pump may be reduced to a point where internal safety devices will shut off the

heat pump

(i.e.: “HP”, “HP5”, “LP” or “LP5”). Maintain equipment as outlined below to prevent water flow

issues:

Operate water filtration devices per manufacturer's specifications. Dirty filters can cause reduced

water flow to the heat pump. The higher the pressure on the filter gauge, the lower the flow rate.

Keep baskets free of debris. Similar to a dirty filter, large volumes of debris in the pump and

skimmer baskets can reduce water flow.

Check for improper valve settings. A partially closed valve after the filter, or a full-open bypass

around the heat pump, will cause insufficient water flow through heat pump.

3.2.c Adjusting Water Flow using

∆T (Delta-T)

CAUTION

- Failure to heed the following may result in equipment damage.

Do not exceed 5°F ∆T on a titanium condener.

The ∆t is the difference in water temperatures going in and out of the heat pump. The equipment can be

fine-

tuned for maximum performance by balancing water flow rates to maintain an ideal ∆T for both the

source-side and pool-side water. See Table 7 for correct temperatures. If you are unsure what condenser

type your heat pump uses, take front panels off the equipment and compare to figures starting on page 8.

Please note that source-side and pool-side equipment may have different condenser types.

1)

Turn heat pump thermostat to its lowest setting while in “HEA” mode.

2) Turn off water pump.

3) Turn valves leading to heater to half-way open positions.

4) Turn valves leading away from heater to wide-open positions.

5) Turn on pool water pump.

6) Slowly turn up heat pump thermostat until heat pump turns on.