Ridetech 11037199 User Manual

Page 4

4

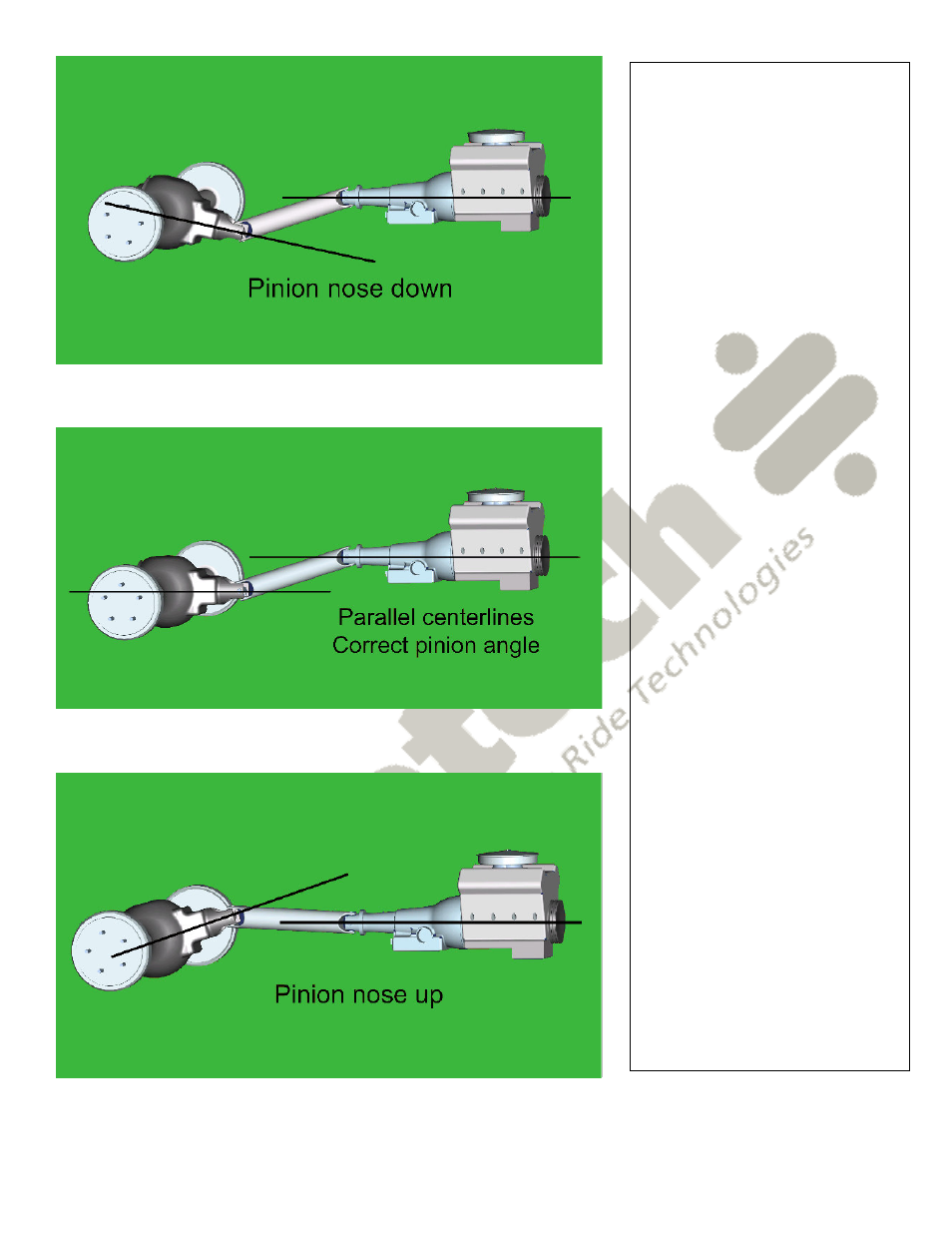

9. How do you set the pinion

angle? On a single-piece

shaft you want to set it up

where a line drawn through the

center of the engine crankshaft

or output shaft of the

transmission and a line drawn

through the center of the

pinion are parallel to each

other but not the same line.

A simple way to do this is to

place a digital angle finder or

dial level on the front face of

the lower engine pulley or

harmonic balancer. This will

give you a reading that is 90

degrees to the crank or output

shaft unless you have real

problems with your balancer.

At the other end, you can

place the same level or angle

finder against the front face of

the pinion yoke that is also at

90 degrees to the centerline.

If you rotate the yoke up or

down so both angles match,

you have perfect alignment.

Road testing will tell you if

you have it right. If you

accelerate and you get or

increase a vibration, then the

pinion yoke is too HIGH.

Rotate it downward in small

increments of a degree or two

until the problem goes away.

If you get or increase a

vibration when decelerating,

then the pinion yoke is too

LOW. Rotate it upward to

correct it.