Nitrous Express Hitman EFI User Manual

Page 2

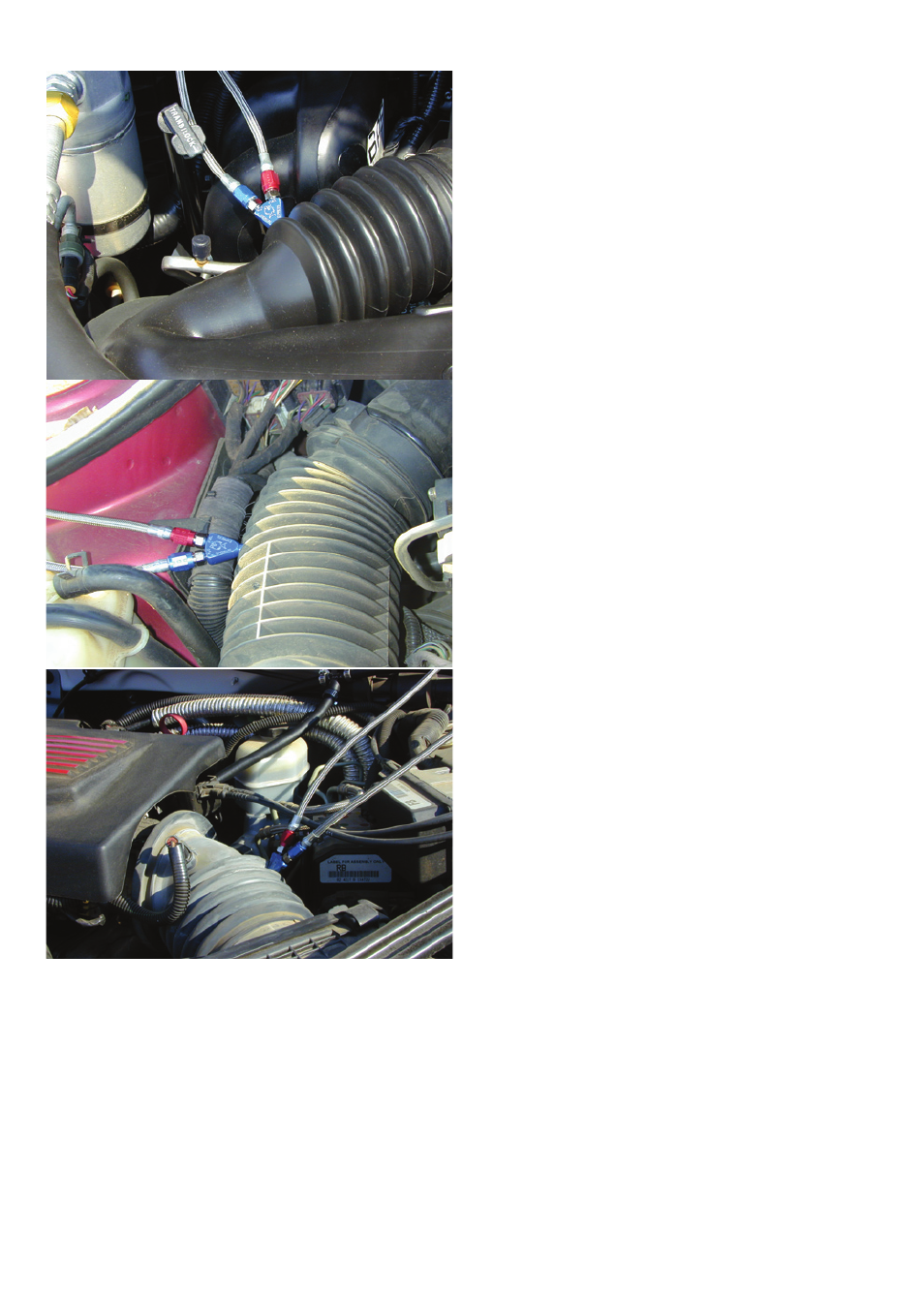

NOZZLE MOUNTING

The location of the nozzle will dictate the loca-

tion of the solenoids, (limited by the 12 inch nozzle

feed lines). The mounting location for the “Piranha”

nozzle on factory installed Fuel Injection systems, is

in the air inlet tube at a point about 2-6 inches before

the throttle body. The actual spacing is not important.

Note: It may be necessary to vary the exact mount-

ing point due to space and/or accessory limitations on

certain models. The above photos should be used as a

guide for proper nozzle location.

Remove the air inlet tube. Drill a 3/16” hole in the

location you have chosen for the nozzle placement.

This area should be as flat as possible to assure proper

sealing of the nozzle.

Using a silicone RTV sealer, apply a thin bead

around the nozzle threads. Thread the Piranha nozzle

into the air tube and tighten so the nozzle discharge is

pointing toward the throttle body.

Choose and insert the 35hp N2O and Fuel jets

(REFER TO JETTING CHART) into the nozzle body.

(It is always best to start with the lowest horse power

setting and work your way up) Attach the blue stain-

less braided line to the nozzle fitting labeled N2O and

the red braided line to the nozzle fitting labeled FUEL.

NOTE: Always check each jet for obstructions before

using.

ROUTING THE NITROUS FEED LINE

NOTE: Place a piece of tape over both ends of the

hose to prevent debris from entering the feed line

during the routing process.

The 12-foot D-4AN nitrous feed line may be

routed to the engine compartment either through the

passenger compartment or under the vehicle. Route

the line carefully to prevent the possibility of restrict-

ing nitrous flow. If routed under vehicle, locate and

drill a 3⁄4 inch diameter hole in a suitable area near the

bottle valve for the main line. Starting at the bottle

nipple (Do not attach to the bottle nipple yet) route

the line to the engine compartment. Following the

factory fuel lines is usually the best path.

Note: Keep maximum clearance between all moving

parts, suspension components and hot engine com-

ponents, securing the supply line where possible

(“Zip-Ties” work best here). Be especially careful of

the feed line being near any “HOT” electrical leads a

spark will cause a permanent leak in the nitrous feed

line.

SOLENOID MOUNTING

1. Install all solenoid fittings using Teflon based sealer

(NO TEFLON TAPE PLEASE) at this time. The

N2O filter is mounted to the 1/8 NPT inlet side of

the nitrous solenoid.

2. The optional solenoid mounting brackets are

designed to be universal. Start by mounting the