Nitrous Express MASTER FLO-CHECK PRO (15529) User Manual

Nitrous Express For the car

MASTER FLO-CHECK

PN 15519

MASTER FLO-CHECK PRO

PN 15529

The Flo-Check is used to establish a base line

tune-up for your NX system. Nothing more. After a

clean, full power pass, the final tune-up will be deter-

mined by spark plug readings (see “Power Tuning

Tips” in your nitrous system instructions).

The Master Flo-Check is easy to use and a reliable

way to establish the flowing fuel pressure of your NX

nitrous system:

1. By consulting the jet chart on the reverse side,

select the proper jet required to flow the HP set-

ting on your NX system.

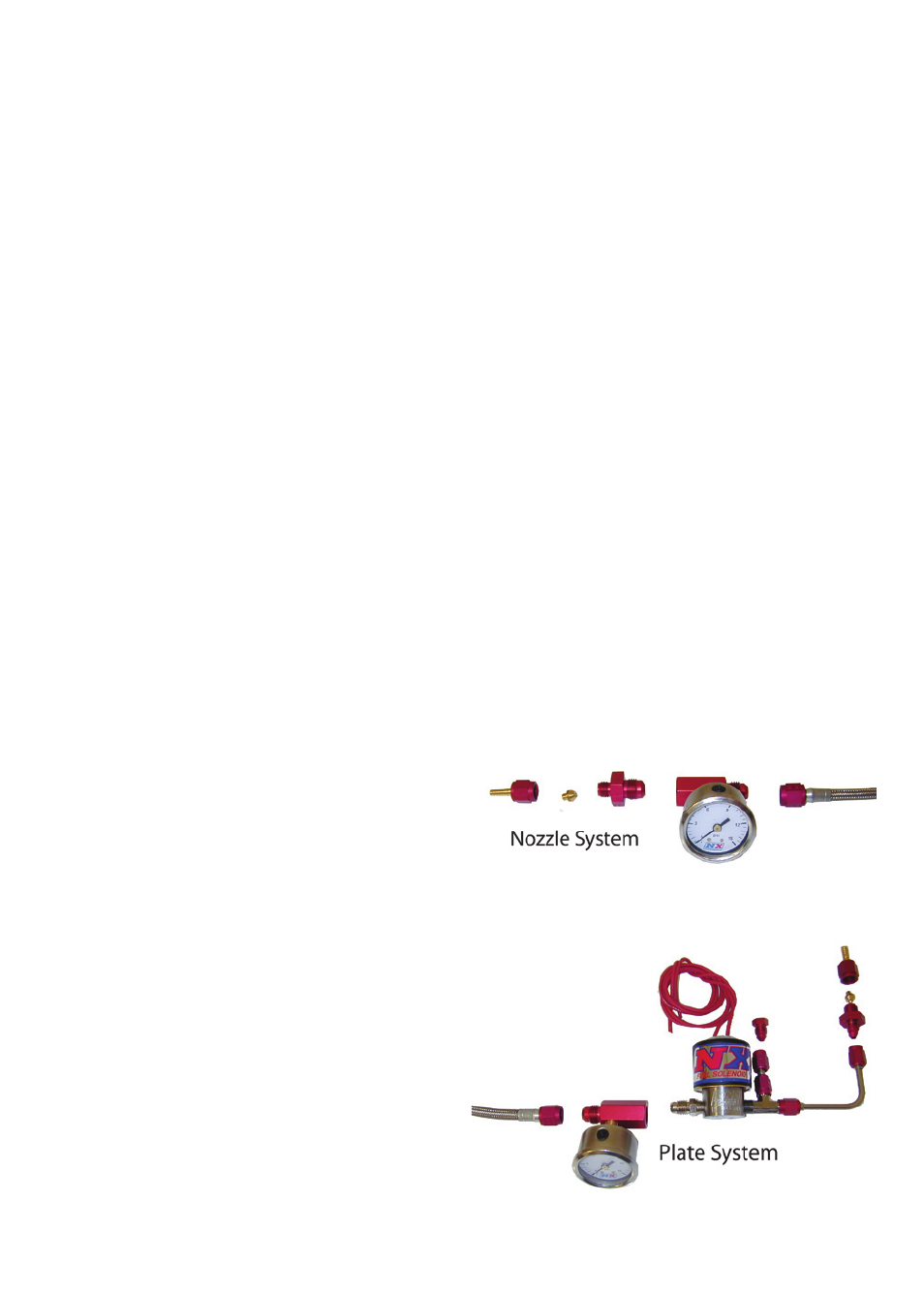

2. Plate systems only. The fuel pressure must be

measured before the fuel enters the solenoid.

Select the proper adaptors, included in the Flo-

Check kit, to connect the supplied pressure gauge

to the proper location on the N2O system fuel

supply side.

3. Nozzle systems only. On either single or double

solenoid nozzle systems the fuel pressure may

be checked anywhere in the fuel system after the

regulator and before the fuel solenoid. Select the

proper adaptors, included in the Flo-Check kit, to

connect the supplied pressure gauge to the proper

location on the N2O system fuel supply side.

4. PN 15529 only. The 6” certified calibration gauge

is designed to operate in the up-right position

only, do not lay flat when checking the fuel pres-

sure! The gauge should be help up right at about

the same height as the fuel solenoid, varying the

height will change the fuel pressure readings.

5. PN 15519 only. Install the supplied fuel pressure

gauge directly on the blue adaptor manifold.

6. Plate systems only. Use the supplied fitting

to secure the jet to the 3/16 stainless steel fuel

jumper line that connects the solenoid to the N2O

plate. Note: On Gemini twin series plates use the

supplied D-3 plug to block one side of the fuel

plumbing.

7. Nozzle systems only. Use the supplied adaptors

to connect the jumper line that leads to either fuel

solenoid to the Flo-Check manifold. Using the

specially modified jet-fitting, insert the proper

flow jet, and install the jet retaining cap.

8. Before beginning the flowing adjustments discon-

nect the power from the N2O solenoid (on plate

systems) to avoid accidental nitrous discharge

into the intake tract and avoid electro-magnet over

heating. On nozzle systems turn the master arm

switch to the “Off” position.

9. Attach a small diameter hose to the jet fitting to

carry the fuel to a safe, approved storage container

away from hot engine parts.

10. Use extreme caution when using this device. Gas-

oline is very flammable and could cause serious

injury or death if ignited.

11. When all cautions have been observed turn the

fuel pump on and using the pressure regulator,

adjust the fuel pressure to the proper level. Note:

Plate systems require the fuel solenoid to be acti-

vated while the fuel pressure is being adjusted.

Your particular application may require the fuel

pressure to be substantially lower than indicated

on the attached chart. If you plug readings indi-

cate an over rich condition lower the fuel pres-

sure in .10 lb increments until the plug readings

improve

Note: The nitrous and fuel solenoids are rated only

for intermittent duty. Do not engage either solenoid

for more than 20 continuous seconds. Solenoids that

have “burned or scorched” electro-magnets will not

be replaced under warranty.