Chapter 6: troubleshooting – Sterlco GC Series Central Chiller User Manual

Page 46

GC Series Central Chillers

Chapter 6: Troubleshooting

46 of 79

Chapter 6: Troubleshooting

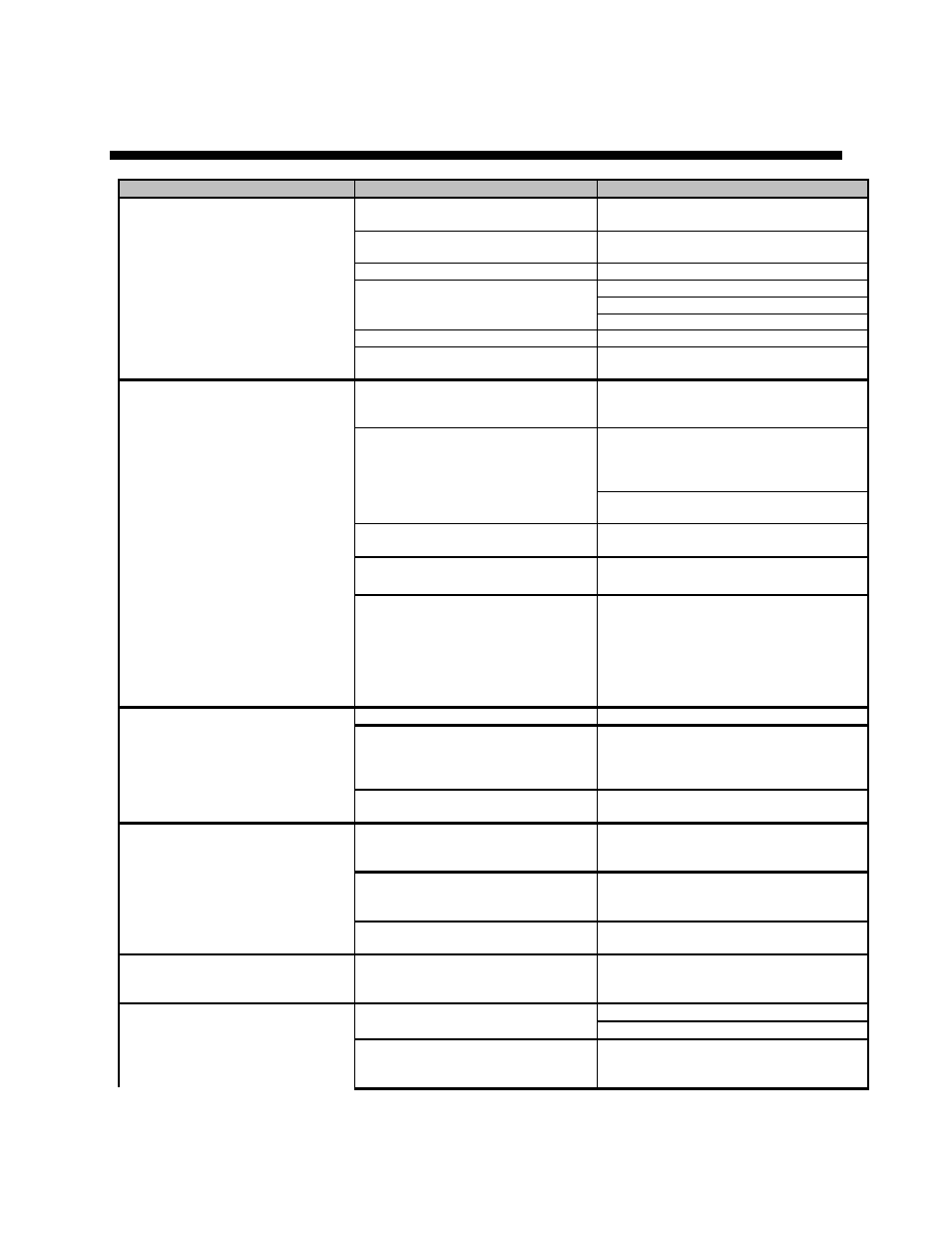

Problem

Possible cause

Solution

Unit does not run.

No power.

Check main disconnect, fuses, wiring,

and power lead to unit.

Wrong voltage supplied to unit.

Voltage must be within plus or minus

10% of nameplate rating.

Defective display.

Replace.

Control circuit fuse blown.

Replace control circuit fuse.

Check transformer.

Check for a short circuit.

Defective control transformer.

Replace.

Piping flow switch circuit open.

Add water or water/glycol solution as

required.

Pump runs; compressor does not

.

Leaving fluid setpoint

set higher

than temperature of liquid in

system.

Lower the leaving fluid temperature

below the leaving temperature you

desire.

Compressor internal overload or

fuses are open.

Allow time to cool and reset, then check

for high/low volt-age. It must be within

plus or minus 10% of the nameplate

rating.

Check for open fuses and loose

compressor electrical connections.

Compressor contactor holding coil

open.

Repair or replace

Defective compressor auxiliary

contact.

Repair or replace.

Broken wire in the compressor

control circuit.

Locate and repair.

Pump runs, compressor(s) cycle(s)

at short intervals.

Plugged evaporator strainer

Clean

Hot gas not coming on

Check hot gas analog output value

through status screen. Contact Service

if output value remains at 0%

throughout compressor cycle.

Low water flow

Install bypass between to-and-from

process line

Water temperature is too high.

Water/glycol mixture inadequate

for process.

Make sure that the water/glycol mixture

protection is right for the process.

Improperly set leaving fluid

temperature, warning, or fault set

point

Adjust.

Refrigerant charge is low.

Call service to find and repair the leak,

then have refrigerant added.

Pump process pressure is too high.

Restricted water flow.

Check for partially closed valves etc.

Make sure that all lines are properly

sized.

Unit runs continuously, but not

enough cooling power

.

Restricted condenser air flow.

Clean filters.

Clean condenser.

Unit low on refrigerant.

Check the refrigerant charge by viewing

sight glass on liquid line upstream of the

expansion valve.