7 air handling system insulation considerations – Sterlco SBFC Series Blown Film Coolers User Manual

Page 21

SBFC Series Blown Film Cooling Systems

Page 21

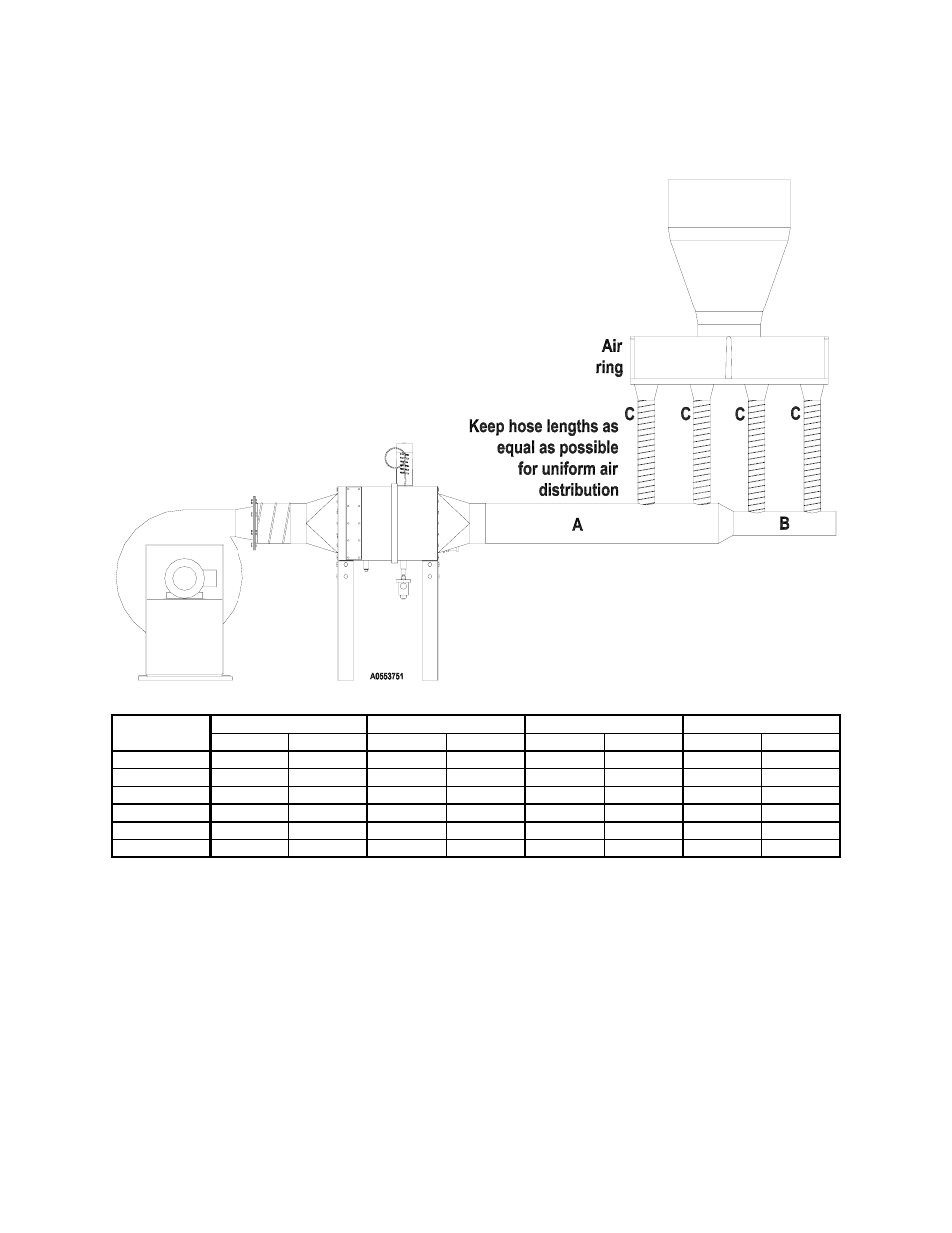

Figure 10

Typical Four-Point Air Distribution System

Model Air

flow

A

B

C

number

cfm

cmh in. cm in. cm in. cm

SBFC600B 600

1,019.0

10”

25.4

cm 6” 15.2

cm 4” 10.2

cm

SBFC1000B 1,000 1,699.0 10” 25.4

cm 7” 17.8

cm 5” 12.7

cm

SBFC1500B 1,500 2,548.5 14” 35.6

cm 9” 22.9

cm 7” 17.8

cm

SBFC2000B 2,000 3,389.0 14” 35.6

cm 10” 25.4

cm 7” 17.8

cm

SBFC3500B 3,500 5,946.5 16” 40.6

cm 12” 30.5

cm 9” 22.9

cm

SBFC5000B 5,000 8,495.0 18” 45.7

cm 14” 35.6

cm 10” 25.4

cm

3-7 Air Handling System Insulation Considerations

Your Sterling/Sterlco SBFC Series blown film cooler comes

equipped with factory insulation. To eliminate condensation, you

should insulate the rest of the air handling system. Make sure that

you insulate ductwork from the air discharge transition as well as

all flexible tubing. An acceptable thickness of insulation is ½” (1.3

cm), using a light density expanded rubber.