Diagnostic alarms – Sterlco Micro Series Water Temperature Control Unit User Manual

Page 20

3200

Series

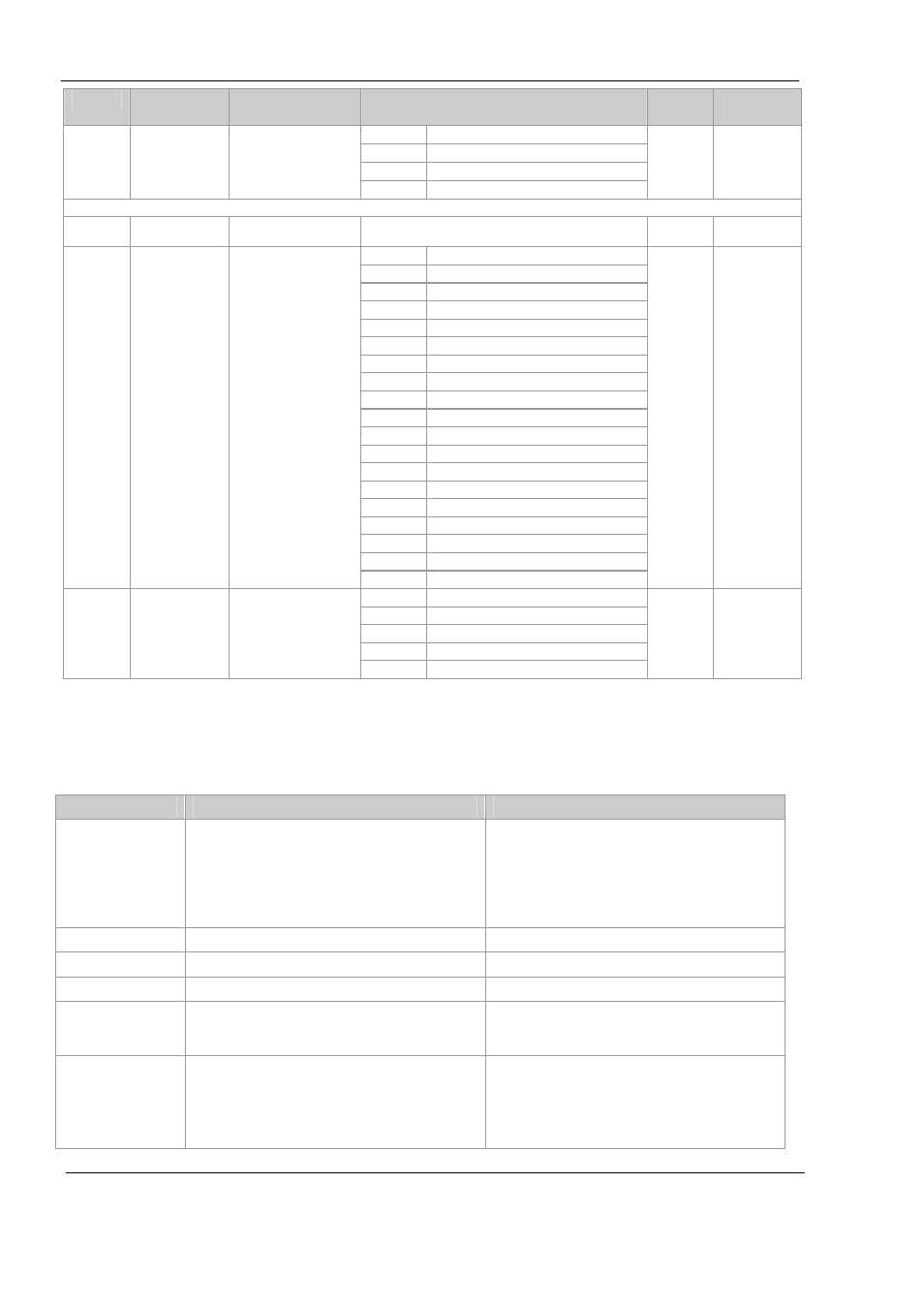

20 ACS 3216 Operators Manual

Name

Scrolling

Display

Parameter

Description

Value

Default

Access Level

IdLe

Normal operating state

Lo

Low offset

Hi

High offset

u c a l

USER

CALIBRATION

To select low and high

offset state or reset to no

offsets.

rEST

Remove high and low offsets

IdLE

L3 only

The following parameters appear when calibrating the controller ie UCAL = Lo or Hi

c . a d j

CALIBRATION

ADJUST

To set an offset value.

-1999 to 9999

L3 only

none

Not selected

0

Select mV low calibration point

50

Select mV high calibration point

150r

Select PRT low cal point

400r

Select PRT high cal point

CJC

Select CJC calibration

Ct 0

Select CT low cal point

Ct 70

Select CT high cal point

Fact

Return to factory settings

Ima.L

Low mA output from I/O 1

Ima.H

High mA output from I/O 1

2ma.L

Low mA output from output 2

2ma.H

High mA output from output 2

3ma.L

Low mA output from output 3

3ma.H

High mA output from output 3

rm.VL

Remote setpoint input low volts

rm.VH

Remote setpoint input high volts

rm.CL

Remote setpoint input low current

p h a s e

CAL PHASE

To calibrate low and high

offset

rm.CH

Remote setpoint input high current

none

Conf only

NO

Yes

Start

Busy

Calibrating

Pass

Calibration successful

G O

To start the calibration

sequence

faiL

Calibration unsuccessful

NO

Conf only

8. Diagnostic Alarms

Diagnostic alarms indicate a possible fault within the controller or connected devices.

Display shows

What it means

What to do about it

E.Conf

A change made to a parameter takes a finite time to be

entered. If the power to the controller is turned off

before the change has been entered then this alarm will

occur.

Do not turn the power off to the controller while

ConF

is flashing

Enter configuration mode then return to the required

operating mode. It may be necessary to re-enter the

parameter change since it will not have been entered in

the previous configuration.

E.CaL

Calibration error

Re-instate Factory calibration

E2.Er

EEPROM error

Return to factory for repair

EE.Er

Non-vol memory error

Note the error and contact your supplier

E.Lin

Invalid input type. This refers to custom linearisation

which may not have been applied correctly or may have

been corrupted.

Go to the INPUT list in configuration level and set a

valid thermocouple or input type

Emod

IO1, OP2, or OP3 has been changed

If this has been field changed by the installation of a

new board, enter config level, then exit back to operator

level.

If the message occurs at any other time return to factory

for repair.