Setra System Model 204D User Manual

Page 4

Electrical Information for Optional ±15 VDC (Option 622) and ±24VDC (Option 621)

Excitation Pressure Transducers

Note: Any figures in parentheses ( ) pertain to the ±24 VDC excitation units only.

Connections

Cable Lead

Function

Note: Other leads in the

White

+15 (+24) Positive Excitation

cable are not used for

Black Power Supply Ground

electrical Option 621 and 622

Violet

- 15 (-24) Negative Excitation

unless the transducer has been

Yellow

Positive Output

wired for Remote Control (see Remote

Brown

Negative Output

Instructions)

Shield Case

Electrical - Electrical Option 622 permits operation from a ±15 VDC and electrical Option 621

permits operation from a ±24 VDC supply (common return grounded), and provides you with

the negative signal output lead also at the common ground potential. Thus many transducers

can be operated from one power supply into single-ended loads. Circuit is reversed voltage

protected for at least 5 minutes. Internal transient suppression network is provided for short

duration transients to 150 volts.

Grounding - For general usage and best results (lowest noise) grounding of the shield/case

to the black lead is recommended.

Power Supply Advice - This transducer has been designed to operate from a dual ±15 VDC

(±24 VDC ) source. Stated another way, the supply is a 30V (48V) center tapped supply. The

±15 V (±24 V) is 15 V (24 V) above the common power return lead, and the - 15 V (- 24 V) is 15

V (24 V) below the common power return lead.

All three power leads must be connected. The transducer will not function if just the +15 V

(+24 V) and

-15 V (-24 V) leads are connected to the power source.

To avoid circuit damage due to excessive voltage, the positive supply voltage should be held

within the range of +15 V to +20 V (+22 V to +30 V), and the negative supply voltage should

be held within the range of -10 V to -20 V (-10 V to -24 V).

Note on long cable use:

In some instances, use of long cables (several hundred feet length) may introduce enough

cable capacitance into the circuit to cause output oscillations. If encountered, this oscillation

may be eliminated by connecting a 100 ohm resistor (1/8th watt or larger) in series to each

of the output leads at the end of the 2 foot transducer cable. These series resistors, of course,

add to the output resistance.

Electrical Information for 4 to 20 mA Pressure Transducers

Electrical - The circuit is designed to operate as a true two-wire 4 to 20 mA pressure transducer.

Connection

The Setra 4 to 20 mA transducer has two electrical leads. These may be connected for current

flow in either direction, without change in performance or damage. We suggest that the electri-

cal cable shield be connected to the system loop circuit’s ground, thereby improving electrical

noise rejection.

4

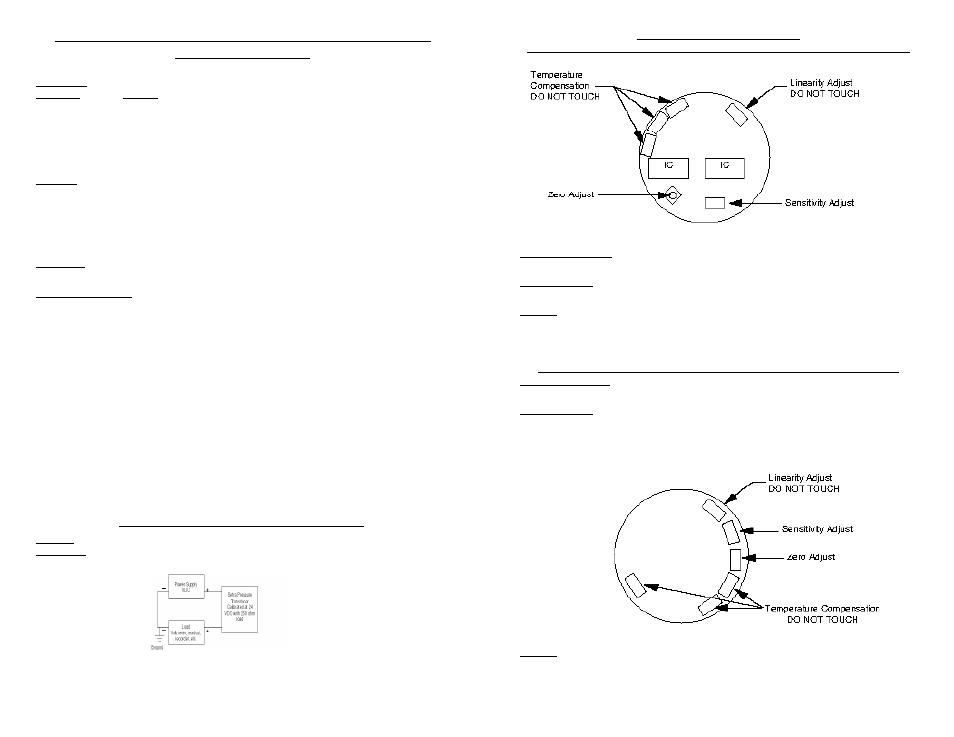

Adjustments for Zero and Sensitivity

Adjustments for Voltage Output Pressure Transducers (cover must be removed)

Caution: TURN OFF EXCITATION POWER DURING COVER REMOVAL OR REPLACEMENT

Zero Pressure Output - Can be adjusted to zero by potentiometer as shown in diagram. Unit

factory - adjusted to zero output (±10 mV for Model 204 and ±20 mV for Model 239).

Sensitivity (span) - Can be adjusted by potentiometer as shown on outline diagram. Unit fac-

tory - adjusted to order specifications.

Linearity - DO NOT TOUCH - Factory adjusted for best linearity. Touching any adjustments other

than zero output or sensitivity may necessitate recalibration.

Note: Sensitivity (span) adjustment is not recommended unless a primary pressure standard

(dead weight tester, etc.) is available for use as a reference.

Adjustments for Current Output Pressure Transducers (cover must be removed)

Zero Pressure Output - Zero output can be adjusted ±0.2 mA about the nominal 4 mA. The zero

adjustment is the potentiometer shown in the diagram. Changing zero will not change span.

Sensitivity (span) - Sensitivity can be adjusted approximately ±5 mA from the nominal 16 mA

full scale span. The sensitivity adjustment potentiometer is located as shown in the diagram

and may be adjusted without affecting linearity calibration.

Linearity - DO NOT TOUCH - Factory adjusted for best linearity. Touching any adjustments other

than zero output or sensitivity may necessitate recalibration.

Note: Sensitivity (span) adjustment is not recommended unless a primary pressure standard

(dead weight tester, etc.) is available for use as a reference.

5