Setra System Model 204D User Manual

Page 3

Electrical Information for Standard 24 VDC Excitation Pressure Transducers (nominal)

Connections (Model 204, 239)

Cable Lead

Function

Note: Other leads in the cable are not used with

White

Positive Excitation

the standard pressure transducer unless the

Yellow

Positive Output

transducer has been wired for Remote Control

Brown

Negative Output

(see Remote Control Instructions).

Black

Negative Excitation - (to circuit ground)

Shield Case

Connections (Model 204, 239) (Grey or White Cable)

Cable Lead

Function

Red

Positive Excitation

Black

Negative Excitation

White

Negative Output

Green

Positive Output

Shield Case

Electrical - The electrical circuit is equivalent to a 4 terminal network, which means negative

excitation lead shall not be connected to negative signal output lead.

The pressure transducer must be operated with the case connected to earth ground to meet

EMC requirement. Best performance will be achieved by connecting the shield and negative

excitation lead if it is feasible and allowed.

The circuit has internal protection:

Reversed excitation voltage for at least 5 minutes.

Short-circuit or signal output leads.

Short duration power line transients up to 150 volts.

Note on long cable use:

In some instances, use of long cables (several hundred feet length) may introduce enough cable

capacitance into the circuit to cause output oscillations. If encountered, this oscillation may

be eliminated by connecting a 100 ohm resistor (1/8th watt or larger) in series to each of the

output leads at the end of the 2 foot transducer cable. These series resistors, of course, add to

the output resistance.

Atmospheric Reference (Gauge Pressure Transducers only)

Lower range units are subject to excessive thermal zero shift unless vented to atmosphere. The

electrical cable provides this equalization vent. Do not seal the electrical cable when installing

3

Fixed

Adjustable

6

Remote Control Instructions for Pressure Transducers

Cable leads indicated below are connected into the transducer circuitry on this transducer as ordered.

Connection of the remote control leads extends the internal zero and sensitivity adjustments. The

Transducer was factory calibrated with the remote control wiring disconnected.

CAUTION: The remote control leads directly access active circuit elements. Inadvertent short-circuiting

to each other, to ground, or other miswiring may cause immediate circuit damage. Keep remote control

wiring either free of other contact or else keep the leads properly wired as shown below.

Note: All resistance elements are 0.1 watt or greater. All remote circuits have voltages less than 10

volts and currents less than 1 mA.

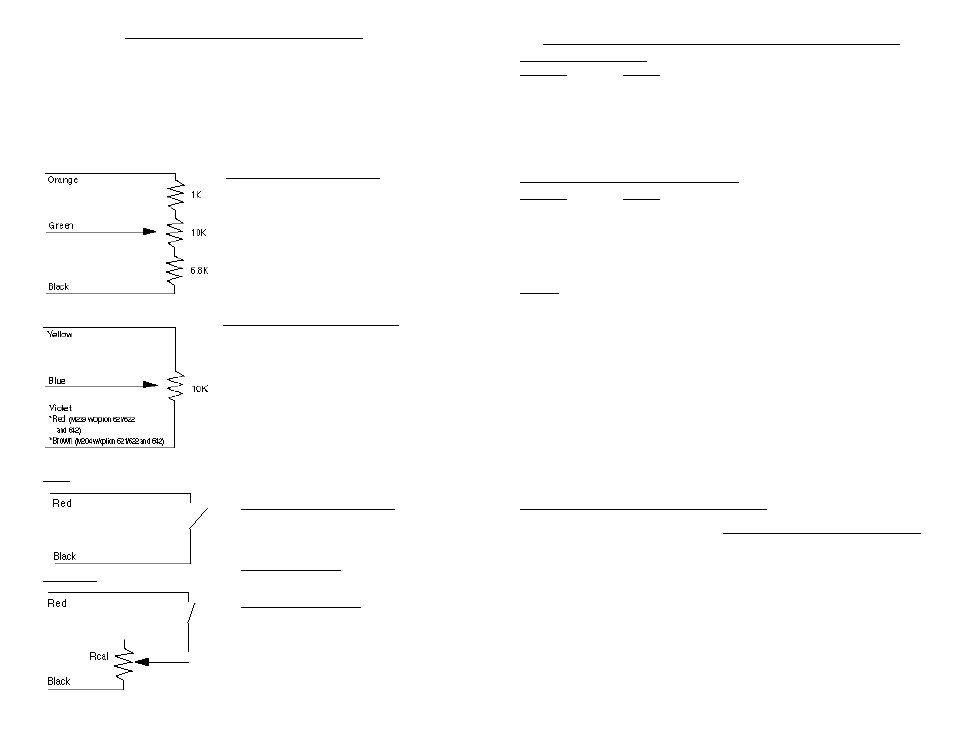

Remote Zero Adjustment (standard)

The transducer has been preset with the regular

internal zero adjustment potentiometer. If remote

zero control is desired, connect the orange, green

and black leads as shown with external resistors

and potentiometers.

Remote Sensitivity Adjustment (optional)

The transducer has been preset with the regular

internal sensitivity adjustment potentiometer. If

remote sensitivity control is desired (Option 642),

connect the yellow, blue and violet* leads and

adjustable resistance as shown.

*For Models 239 and 204 w/options 621/622 and

642, replace violet lead as shown.

Remote Calibration Signal (optional)

Two types of calibration signal zero offset are

offered:

Fixed calibration signal closing red to black

leads.

Adjustable calibration signal, on closing circuit

with an adjustable resistance between red and

black leads. Suggest use of a 100K potentiom-

eter.