3 mam axes select byte, 4 making a multi-axis measurement, Mam axes select byte – PNI RM3000-F Sensor Suite User Manual

Page 34: Making a multi-axis measurement, Table 5-3: mam axes select bits

PNI Sensor Corporation

Doc #1016102 r04

RM3000-f & RM2000-f Sensor Suite User Manual

Page 34

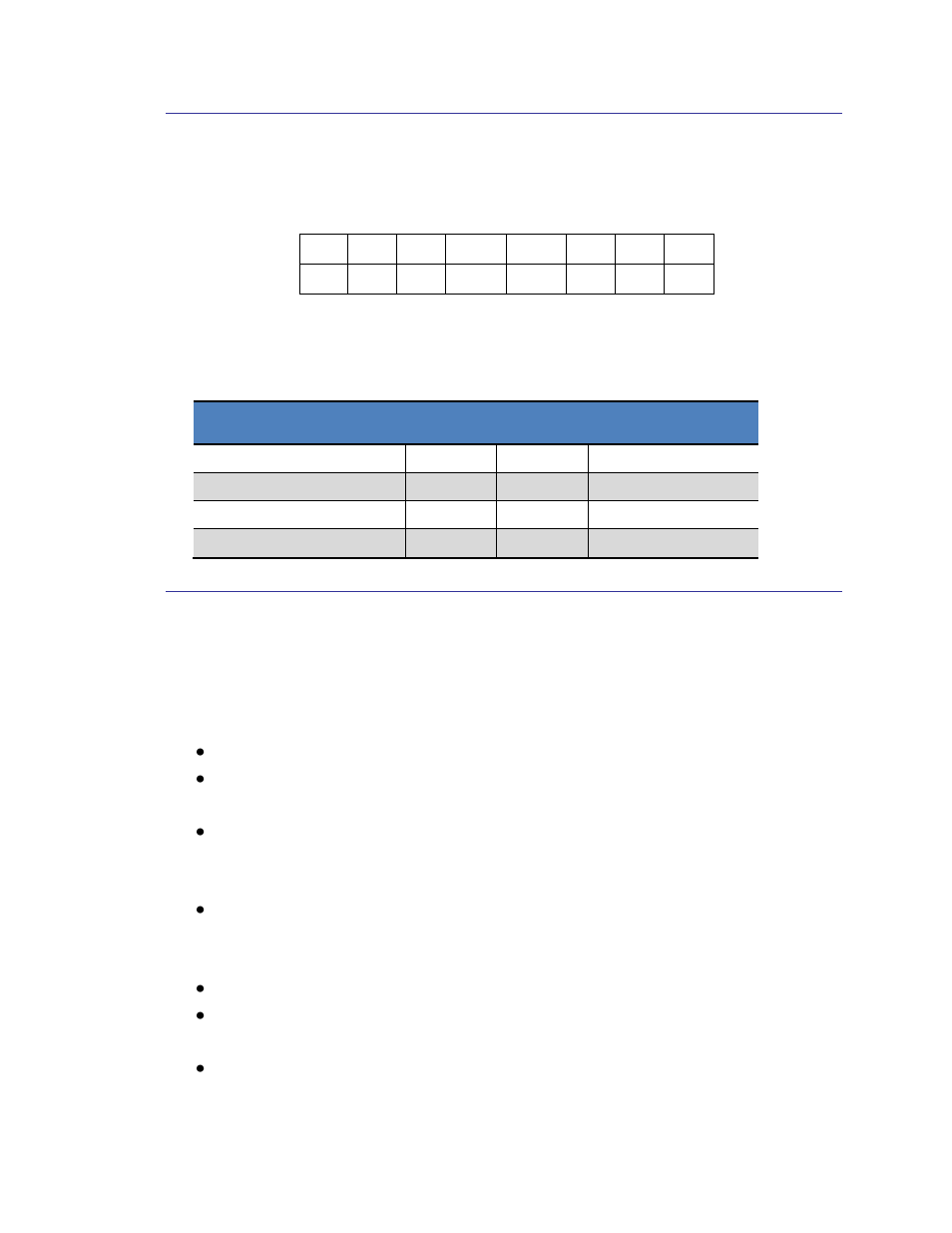

5.3.3 MAM Axes Select Byte

The MAM Axes Select Byte establishes which axes are to be measured and initiates a

multi-axis measurement. It is defined as follows:

Bit #

7

6

5

4

3

2

1

0

Value

0

0

0

AAX1 AAX0

0

0

1

Table 5-3: MAM Axes Select Bits

Axes to be Measured

AAX1

AAX0

Axes Select Byte

X, Y, and Z

0

0

0x01

X and Y

0

1

0x09

X only

1

0

0x11

No axis measured

1

1

0x19

5.3.4 Making a Multi-Axis Measurement

The steps to make an interrupt-driven multi-axis measurement are given below. The 3D

MagIC will return the result of a complete forward-reverse measurement of each sensor

in a 24-bit 2’s complement format (range: -8388608 to 8388607).

Start with SSN set HIGH, then set SSN to LOW.

Send 0x82 on the MOSI line. This is the MAM Command Byte that sets up the

3D MagIC to make a new measurement,

Send by 0x01 on the MOSI line. This is the Axes Select Byte which specifies that

a 3-axis measurement is to be taken. The 3D MagIC will now take the prescribed

measurements.

Return SSN to HIGH. This will not affect the measurement process, but will free

up the host to communicate with other devices and ensure the next Command

Byte sent to the 3D MagIC is interpreted properly.

A measurement is taken.

At the end of the measurement, the DRDY pin is set HIGH, indicating data is

ready, and the 3D MagIC is placed in Idle Mode.

When the host is ready to read the measured values, set SSN to LOW. If SSN

already is LOW, then toggle SSN from LOW to HIGH to LOW.