Drawing and list of replacement parts – NORD Drivesystems B1092 User Manual

Page 16

-16-

B1092-GB

www.nord.com

6. Drawing and list of

replacement parts

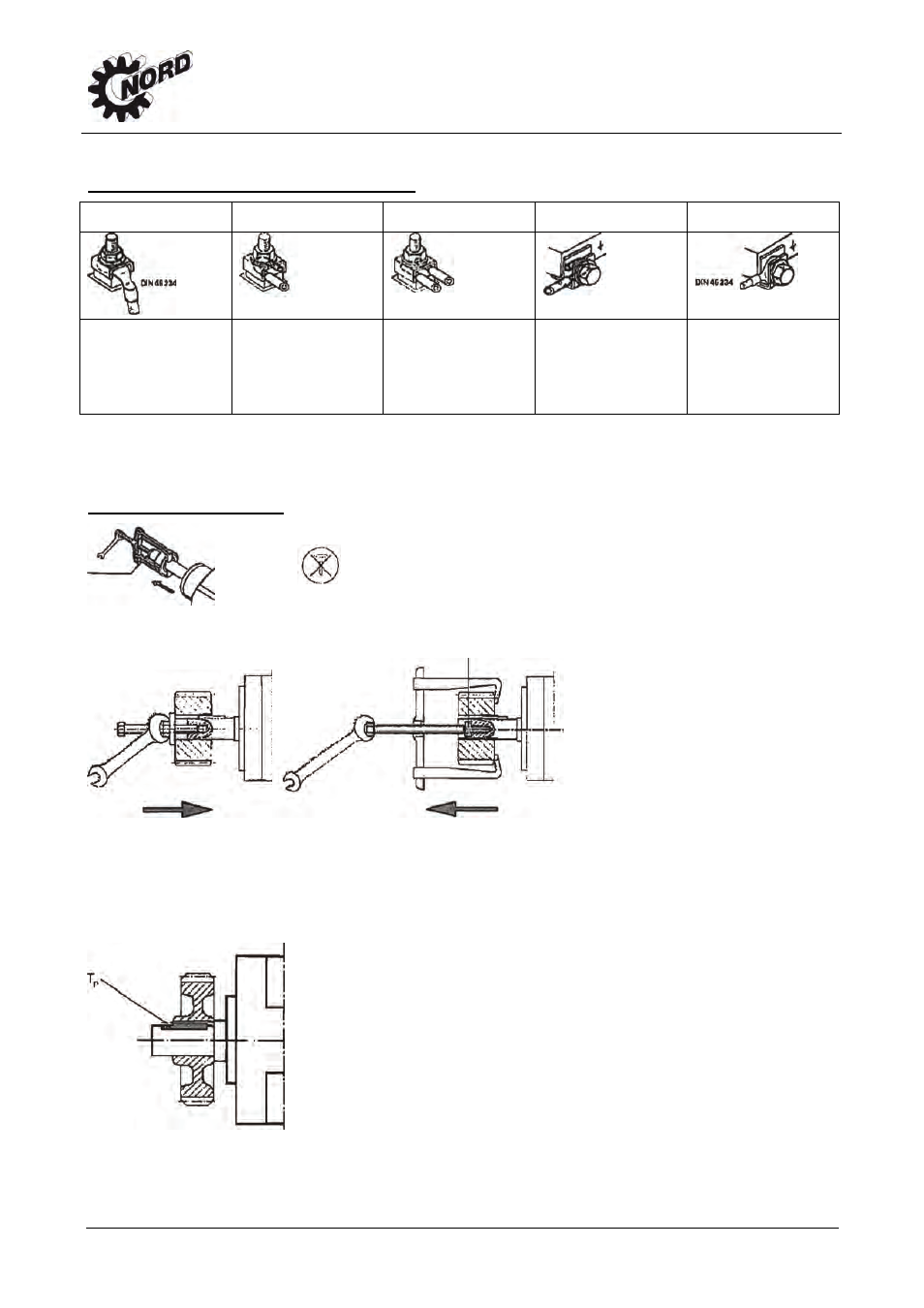

6.3 Cross sections which may be connected

…25 mm

2

…10

mm

2

…25

mm

2

…10

mm

2

…25

mm

2

For connection with

a DIN fork terminal,

the fork terminal

must be angled

downwards.

Connection of a

single conductor

with retaining clip.

Connection of two

conductors of

approximately the

same diameter with

retaining clip.

Connection of a

single conductor

under the external

earthing bracket.

For connection with

DIN fork terminal

under the external

earthing bracket.

Fig. 5, cross sections which may be connected according to the size of terminal (may be reduced due to the

size of the cable entries)

6.4 Changing the bearings

Fig. 6, Intermediate plate (protection of centring in the end of the shaft)

Fig. 7, fitting and removal of drive elements (intermediate plate to protect the centring at the end of the shaft)

When fitting drive elements (clutch, gear wheel, pulley etc.) use the thread in the end of the shaft and as far

as possible heat the drive elements as necessary. Use suitable equipment for removal. When fitting or

removing, no blows (e.g. with a hammer or similar) or radial or axial forces in excess of those permissible

according to the catalogue may be transferred to the motor bearing via the end of the shaft.

Fig. 8, balancing with half parallel key