Drawing and list of replacement parts – NORD Drivesystems B1092 User Manual

Page 15

www.nord.com B1092-GB

-15-

6. Drawing and list of

replacement parts

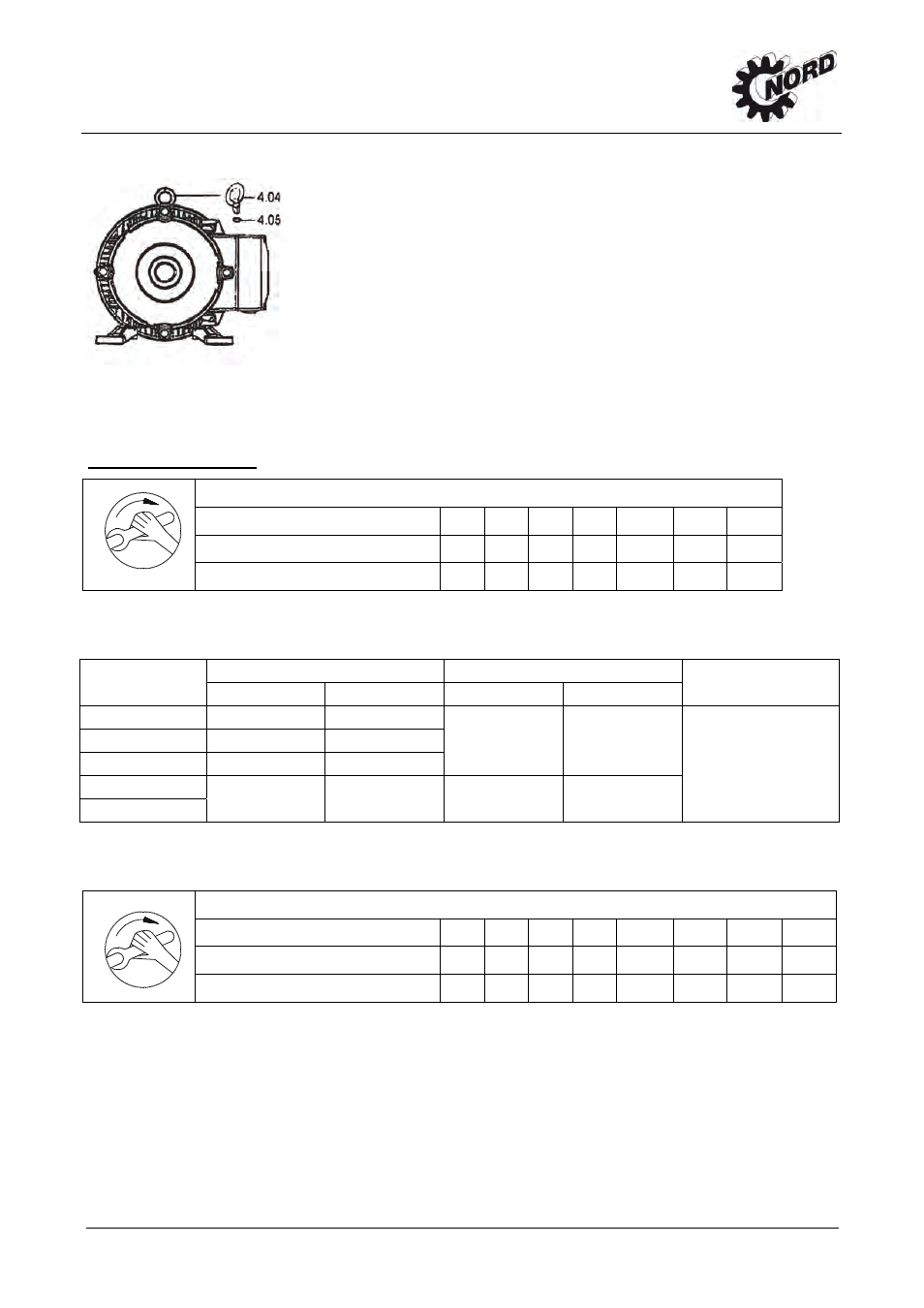

Fig. 3, BD 100…160L, version with lateral configuration of upper section of terminal box (rotatable 4x90

degrees)

6.2 Tightening torques

Tightening torques for terminal board connections

Thread

diameter

M4 M5 M6 M8 M10 M12 M16

Tightening torque (Nm) min.

0.8 1.8 2.7 5.5 9.0 14.0 27.0

Tightening torque (Nm) max.

1.2 2.5 4.0 8.0 13.0 20.0 40.0

Fig. 4, Tightening torques of screw connections of the electrical connections and terminal board connections

(except for the terminal bar)

(*) (**)

Nm min.

Nm max.

Nm min.

Nm max.

O-ring thickness

mm

M12x1.5 4 5

M16x1.5 5

7.5

M25x1.5 6 9

2

3

M32x1.5

M40x1.5

8 12 4 6

2

Fig 4.1, Tightening torques for cable connectors made from metal (*) and plastic 9**) for direct attachment to

motor. For other connectors (e.g. reducers) the corresponding torques according to the table should be used.

Tightening torques on terminal box

Thread

diameter

M4 M5 M6 M8 M10 M12 M16 M20

Tightening torque (Nm) min.

2

3.5

6

16 28 46 110 225

Tightening torque (Nm) max.

3

5

9

24

42

70

165

340

Fig. 4.2, tightening torques for screws on the electrical terminal box, on bearing covers and on screw

connectors for bonding cables

The above values apply unless other values are stated.

e.g. outlet for cables and wires - at bottom