Figure 1: unsuitable mounting locations – Dwyer ULT User Manual

Page 2

TEMPERATURE/PRESSURE DERATING

TEMPERATURE °C

UNACCEPTABLE

RANGE

O

P

E

R

A

T

IN

G

P

R

E

S

S

U

R

E

P

S

I

ACCEPTABLE

RANGE

40

30

20

10

0

-40 -20 0 20 40 60 80

OpeRaTinG pRinCipLe

Ultrasound is sound with a frequency greater than the upper limit

of human hearing; approximately 20 kilohertz. The ULT contains

an ultrasonic transducer and a temperature sensing element.

The ultrasonic transducer transmits ultrasound wave pulses

through air directed towards the material of which the level is

desired. The ultrasound waves then reflect off of the material as

an echo and travel back to the transducer. The level of the

material is determined by the transit time of the ultrasound wave

pulse from the sensor to material and for the echo to come back

to the sensor. The speed of sound through air is sensitive to the

air temperature. The ULT uses the temperature sensing element

to compensate for air temperature changes.

The ULT incorporates patented surface processing technology

and adaptive signal processing. Surface processing technology

filters out all signal obstructions that may be in the tank creating

an effecting beam diameter of only 3˝ (7.6 cm). This beam diam-

eter is a straight column and not cone shaped like competitor

units. Adaptive signal processing continuously optimizes sensor

power, output filtering, and environmental noise rejection.

inSTaLLaTiOn

Unpacking

Remove the ULT from the shipping carton and inspect for dam-

age. If damage is found, notify the carrier immediately.

Materials

The ULT may be used to detect level of a variety of materials.

Since the sensing technology is non-contact it is well suited for

corrosive, coating, slurry, or sticky media. The hazardous

approval rating also makes the unit ideal for use with hazardous

rated applications. Please see the specifications section for haz-

ardous approval classifications.

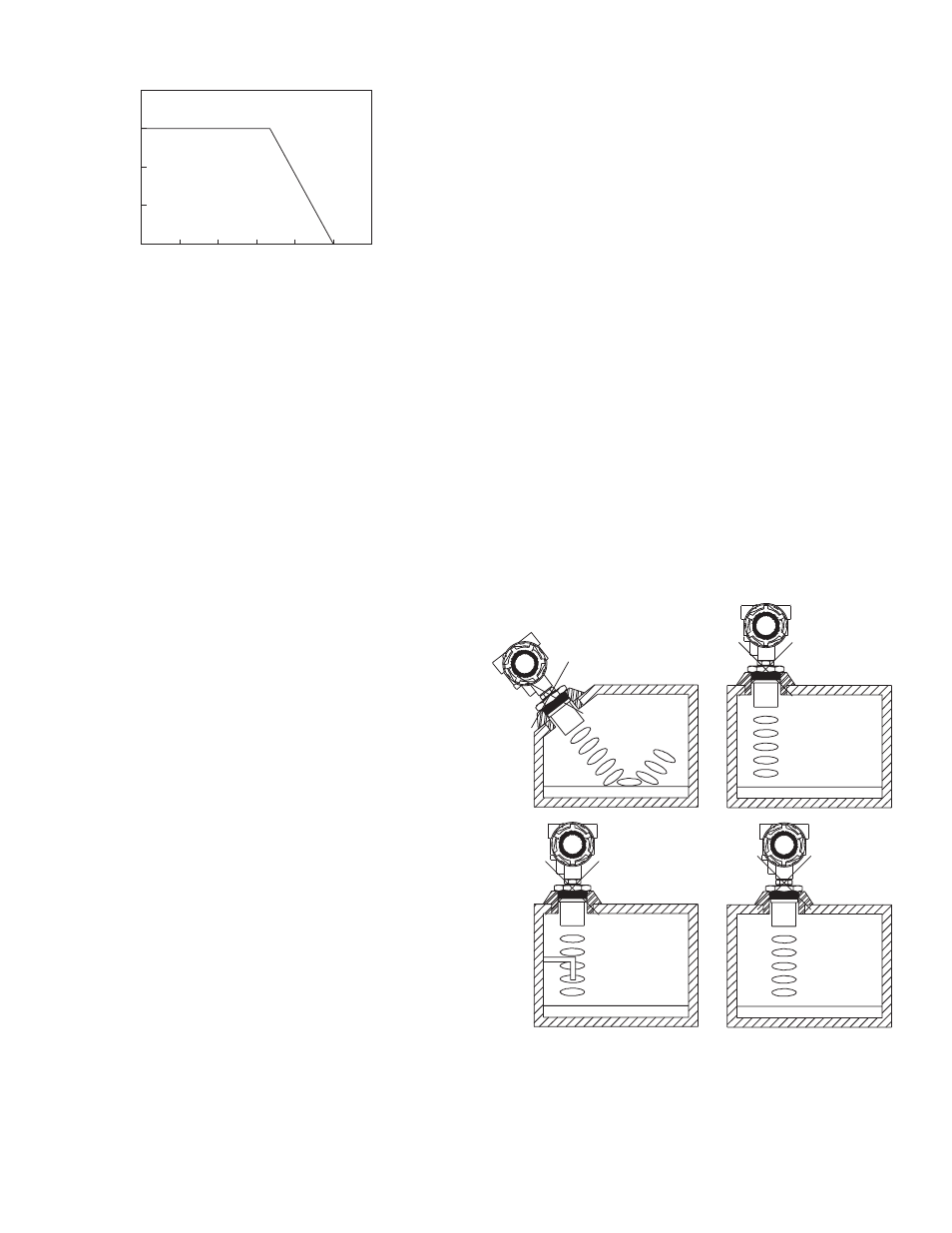

Mounting Location

• The process temperature and ambient temperature must

be within the specified limits.

• The probe must be located away from tank inlets or

chutes where material may fall on the probe during

filling or emptying.

• The probe must be located at least 3˝ (7.6 cm) away

from the tank side wall.

• The probe cannot be used in vacuum applications.

• The probe must be installed vertically and perpendicular

to the media surface.

• Make sure the covers are accessible to allow for

programming, wiring, and ability to see the display.

DO NOT INSTALL

WITHIN THREE INCHES

OF TANK SIDE WALL

DO NOT INSTALL

IN APPLICATIONS

WITH VACUUM

VACUUM

figure 1: Unsuitable Mounting Locations

DO NOT INSTALL AT

AN ANGLE RELATIVE

TO THE LIQUID

DO NOT INSTALL

WITH OBJECTS

IN THE BEAM