Dwyer TM2 User Manual

Page 2

Section II. INSTALLING YOUR MODEL TM2

Mounting the display

When choosing a place to mount the display, keep these three

things in mind:

a.

The display should not be mounted near a solenoid or

other inductive device.

b.

Enough ventilation should be supplied to keep the

totalizer operating within the temperature

specifications (see Selection 5).

c.

This display should not be mounted in a heavy

vibration area.

The recommended mount for the Model TM2 display is panel-

mount. The recommended panel cutout for the display is 2.677˝

wide (68 mm) by 1.299˝ tall (33 mm).

To install the unit in a panel, first remove the two fasteners

located on the side of the unit. These slide tightly in grooves and

should slide out without too much trouble. DO NOT MISPLACE

THESE FASTENERS!!!

With the fasteners removed, the display should slide into the

panel cutout. The included gasket should be between the panel

and the face of the display. Making sure the gasket is properly

aligned and not twisted, slide the display in place. Reinstall the

fasteners by sliding them in their grooves until they stop. The

screws on the fasteners should be facing the panel and the head

of the screw facing away from the panel.

Tighten the set screws of the fasteners using a flathead

screwdriver in a clockwise motion. They should be equally

tightened until the display is snug and the gasket is reasonably

compressed.

When mounted with the provided fasteners, gasket, and specific

rectangular panel cutout, the Model TM2 display achieves a

NEMA-4X rating.

Electrical connections to the display

The Model TM2 is self-powered using an internal lithium battery,

thus there is no need for external power. The typical life of this

battery is 5 years.

After connections are made, power the display by removing the

temporary insulator on the back of the unit. Simply pull the white

tab out -- there is no need to open the battery cover.

Pin #1:

This pin should be connected to the ground of the

pulse signal. In most cases, this will be the same

as the ground of the Flo-Sensor that the Model

TM2 Display is connected to.

Pin #2:

This pin is not used with any Dwyer Instruments,

Inc. products.

Pin #3:

This is the pulse signal input. The Model TM2

accepts all TF10xx Series Flo-Sensor pulse

outputs. These are 7.5VDC peak squarewave

pulses directly proportional to the flow rate.

Pin #4:

This pin is used for remote reset. When

momentarily connected to ground, this pin will

reset the totalizer just like the front panel reset

button.

Pin #5:

This pin is used to enter program mode. When

connected to the ground, the Model TM2 enters

program mode, described in Section 3.

Pin #6-Pin #8:

These pins are not functional.

See the last page for wiring diagrams of connections to various

Flo-Sensors and other products.

Wiring Recommendations

Following these suggestions will increase noise immunity and

lengthen unit life.

Cable: The connection between the count source and the

totalizer/ratemeter should be made with a two-conductor

shielded cable. The shield should be connected to earth ground

at one end only. The connecting cable should not be run in

conduits with cables switching high inductive loads.

Relay Coil Suppression: If a relay contact is used as a count

source, the relay coil should be suppressed. This can be

accomplished with an RC network for AC coils or a diode for DC

coils.

Mounting: This totalizer/ratemeter should not be mounted near a

solenoid or other inductive devices. Enough ventilation should

be supplied to keep the totalizer operating within the temperature

specifications. Do not mount this unit in a heavy vibration area.

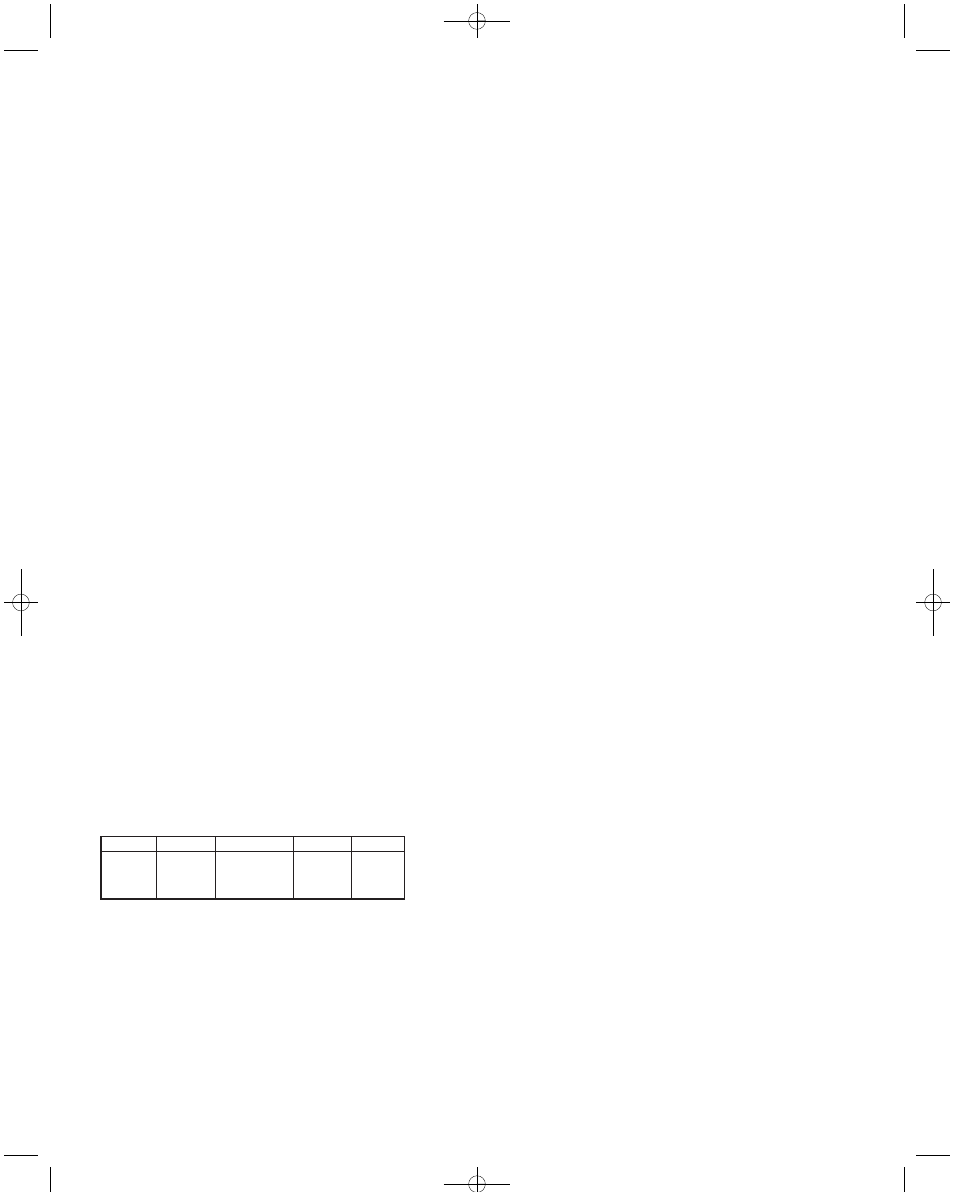

Pin #1

Signal &

Reset

Ground

Pin #2

Not Used

Pin #3

Signal In

(Pulse Input)

Pin #4

Remote

Reset

(optional)

Pin #5

Enable

Program

Mode

F-41-TM2:Model PHO-1 8/24/10 11:51 AM Page 2