Dwyer SSM User Manual

Page 6

RepLaceMent paRtS

Under proper care, there should be no need to stock replacement parts.

If the service or environment is quite harsh, or frequent meter

disassembly dictated, a spare O-ring may be desirable.

Otherwise, parts only need to be replaced if damaged. Any visible

damage to the entire surface of the O-ring or sight tube (particularly from

the bottom edge) indicates need for replacement. To insure accuracy, the

inside surface of the meter core tube, slot edges, and OD of the float

piston should be free of nicks, chips, with no visible erosion of any

surfaces. If abrasive particles are suspended in the meter fluid, it may be

desirable to keep replacement core tube/float assemblies on hand

(Dwyer Instruments, Inc. may also be able to recommend a more

abrasive-resistant construction).

To order parts, include the model and serial number of the units involved,

and description of the part ordered. If converting the meter to a new

application, in addition to the model and serial numbers, SEND DWYER

INSTRUMENTS, INC. COMPLETE APPLICATION DATA INCLUDING

FLUID, MAXIMUM FLOW RATE, MAXIMUM AND OPERATING

PRESSURES

AND

TEMPERATURES,

AND

APPLICATION

PARTICULARS OR FLUID CHARACTERISTICS. This information is

essential for Dwyer Instruments, Inc. to provide proper items, and verify

that the new application is within the operating limits of the flowmeter.

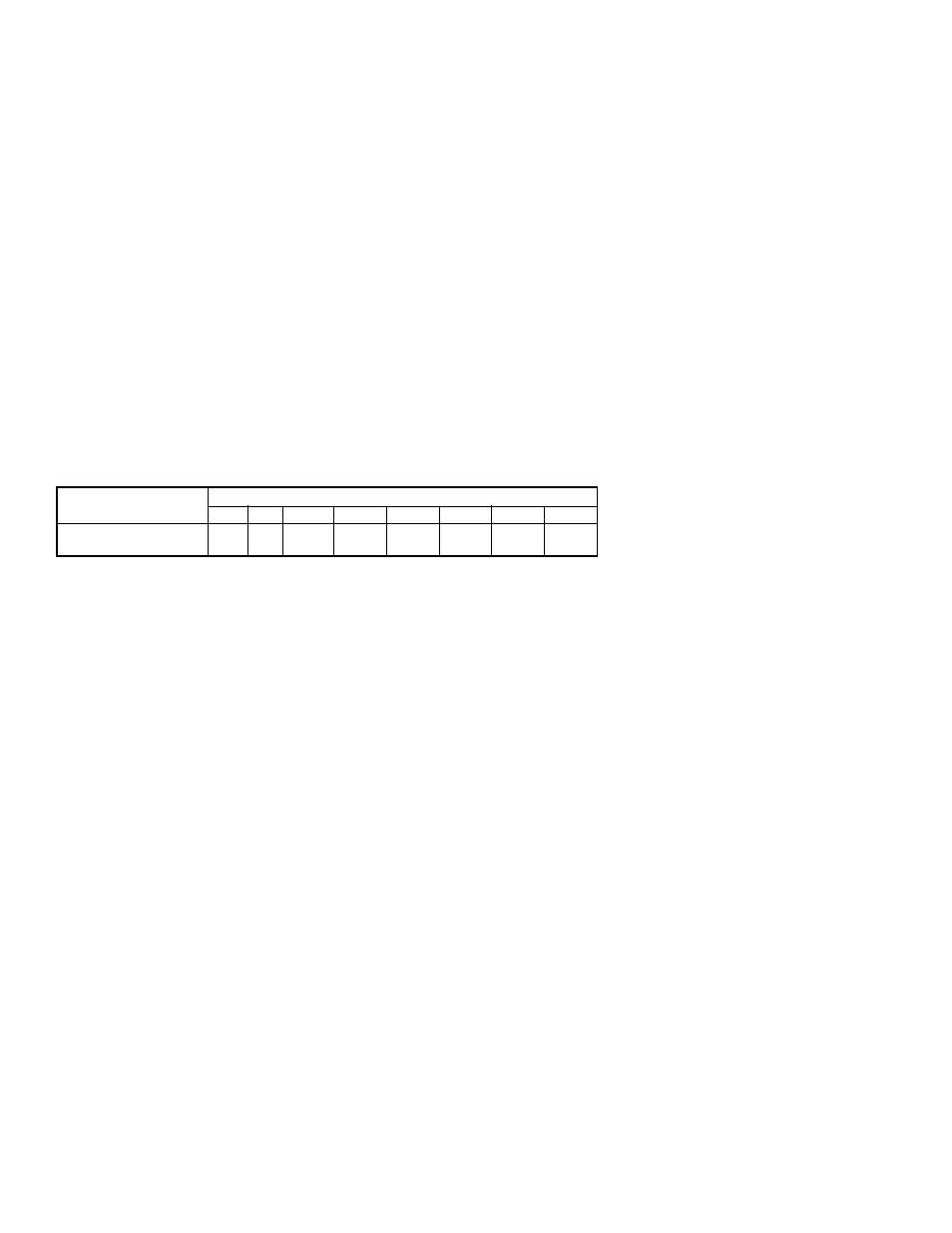

teMpeRatURe VS. pReSSURe, opeRatinG LiMitS, “SeRieS SSM” aLL MetaL fLoWMeteRS*

MeteR SiZe

& MateRiaL

6 (3/4” NPT)-Stainless

12 (1-1/2” NPT)-Stainless

MaXiMUM non-SHocK WoRKinG pReSSURe, pSiG @ ˚f

0˚f

1000

800

350˚f †

990

790

400˚f †

970

780

450˚f †

950

770

500˚f †

930

760

600˚f †

900

750

300˚f †

1000

800

70˚f

1000

800

*

†

OPERATING LIMITS GIVEN ARE BASED ON WATER OR AIR. FOR MORE SEVERE

SERVICE, CORROSIVE, AND OTHER MEDIA AND/OR ENVIRONMENTAL FACTORS, AN

ADDITIONAL CORRECTION FACTOR DOWN-RATING THESE LIMITS MAY BE REQUIRED.

LIMITS ARE BASED ON TESTING AND PRACTICAL EXPERIENCE. POSSIBLE EXTREME

APPLICATIONS CONDITIONS CANNOT BE FORESEEN. THUS, DATA OFFERED ONLY AS

A GUIDE. IT IN NO WAY CONSTITUTES A SPECIFIC RECOMMENDATION OR WARRANTY

EXPRESSED OR IMPLIED.

OPERATING TEMPERATURES ABOVE 300˚F REQUIRE SPECIAL HIGH TEMPERATURE

MODIFICATIONS.