Dwyer CPF User Manual

Page 5

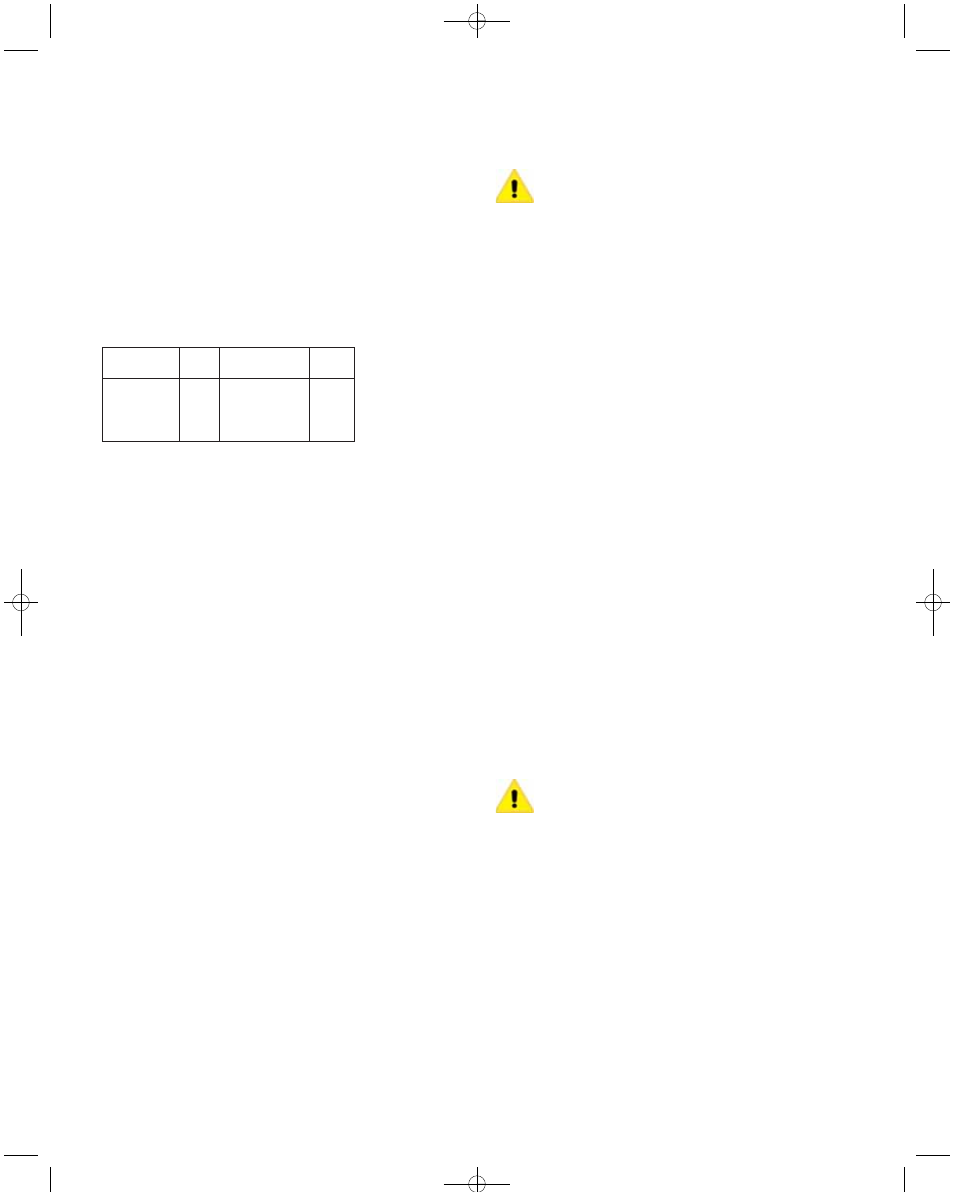

AVERAGE V.I.C., CENTISTROKES, FOR

STANDARD

SERIES PVF AND CPF FLOWMETERS

100% GPM,

SIZE 6

0.54 - 0.80

1.20 - 2.60

3.80 -7.00

10.0 - 23.0

CTS

3

7

15

25

100% GPM,

1-1/2˝ SIZE

11.0 - 15.0

21.0 - 35.0

50.0

70.0 - 120

CTS

50

100

250

500

VISCOSITY CONSIDERATIONS:

Each Series PVF and CPF liquid flowmeters has a so-called

“Viscosity Immunity Ceiling” (V.I.C.). Usually, if the viscosity of

the metered liquid is less than the V.I.C. of the meter, the

accuracy will not be influenced by changes in viscosity. When

greater than the V.I.C., the meter will be influenced significantly,

and must be calibrated for that viscosity. Effects of viscosity on

a given flowmeter are not always predictable. Two apparently

similar liquids with comparable densities and viscosities may

impact meter calibrations quite differently. The table below

provides general guidelines for the typical maximum viscosity for

meter models without affecting accuracy.

MAINTENANCE:

Occasional cleaning of the sight tube and internal sensing

elements to assure float visibility and continued accuracy is the

only maintenance necessary for Series PVF and CPF

Flowmeters. Frequency will depend on the application — in

most cases, and annual cleaning is adequate. It is not necessary

to remove the Series PVF and CPF flowmeters from the pipeline

for cleaning or replacing parts. The body remains plumbed into

the pipe, allowing easy service and even installation of different

sensing elements to accommodate new flow rates or fluids.

Upon final installation of the Series PVF and CPF Flowmeters,

no routine maintenance is required. A periodic check of the

system calibration is recommended. Occasional cleaning of the

sight tub and internal sensing elements us assure float visibility

and continued accuracy is the only maintenance necessary for

the Series PVF and CPF Flowmeters. Frequency will depend on

the application - in most cases, an annual cleaning is adequate.

It is not necessary to remove the flowmeter from the pipeline for

cleaning. Please follow the instructions in the manual under

“Inspection and Cleaning.” The Series PVF and CPF

Flowmeters are not field serviceable and should be returned if

repair is needed (field repair should not be attempted and may

void warranty). Be sure to contact customer service to receive a

return goods authorization number before shipping.

DISASSEMBLY: The spare parts sheet included for each

flowmeter model type ordered includes cutaway drawings.

Please refer to the appropriate sheet during the disassembly

and assembly procedures.

CAUTION:

BE SURE PRESSURE IS FULLY VENTED AND FLUIDS

COMPLETELY DRAINED BEFORE DISASSEMBLING THE

FLOWMETER. WEAR SAFETY GLASSES AND PROTECTIVE

CLOTHING IF THERE IS ANY CHANCE OF EXPOSURE TO

HAZARDOUS CHEMICALS.

The sight tubes of all standard Series PVF and CPF flowmeters

may be removed by, depending on model type: (a) removing the

cotter pins and pulling the lock rings out horizontally; (b)

removing the bolts from the body/sight tube flange; or (c)

removing the internal snap ring with retaining ring pliers. Using

hands only, pull the sight tube straight up out of the body with a

slight twisting motion, lifting it clear of the body and snorkel or

guide rod. Remove the float assembly by lifting it up and away

from the snorkel/guide rod (On PVC and CPVC the

snorkel/guide rod transition assembly must be lifted out with the

float). The core tube assembly may then be lifted out — if stuck,

CAREFULLY pry up at the top of the slot with a brass rod, taking

care not to damage the body or core tube.

INSPECTION & CLEANING

Inspect parts for nicks, scratches, chips, wear, and contaminant

build-up. The edges of the core tube slot, ID of the core tube,

and OD of the piston (largest section at the float assembly

bottom) are precision machined. Damage to these areas can

destroy the meter's accuracy. Also inspect the O-ring, the

bottom section of the sight tube, and the inside of the upper body

section. Damage to these areas may result in leaking. Clean,

rinse, and dry all parts carefully, including the O-ring, preferably

with a mild detergent and water and a soft cloth or soft tube

brush. If solvents are used, make sure they are compatible with

all meter parts (plastic sight tubes may be attacked by chemical

vapors or solvents —consult the factory).

CAUTION:

DO NOT SCRAPE OR USE ABRASIVE MATERIALS FOR

CLEANING.

F-23:TEMPLATE 10/27/09 4:07 PM Page 5