Dwyer PDWS User Manual

Page 6

Problem

Probable cause

try...

No signal

after installation

Inaccurate

metering

Consult Flow Range Chart

Reduce pipe size or use different

sensor

Check connections at control;

Red (+), Black (-), White (signal)

Use 6 to 24 VDC power supply

Add pull up resistor, if using current-

sourcing device

Remove flow sensor from fitting and check

for free spinning; replace rotor

See signal troubleshooting; replace

magnetic sensor

Move meter away from flow disturbance, or

field-calibrate

Check fitting for K-Factor, check indicator to

see if it is entered properly ("Set K" on

RTI)

Remove flow sensor from pipe. If indicator

is an RTI, set K to 1.00, turn rotor slowly by

hand, indicator should count each blade;

replace sensor

If using an RTI, check left side of

display (sec, min, hr, day); change to

desired unit

Insufficient flow

Bad connections to control electronics

Incompatible control

Damaged or missing rotor

Failed magnetic sensor

Not enough straight pipe between meter and

severe flow disturbance

Wrong K-Factor entered

Magnetic sensor failing to pick up each blade

Wrong time units on flow indicator

tROubleShOOtiNG

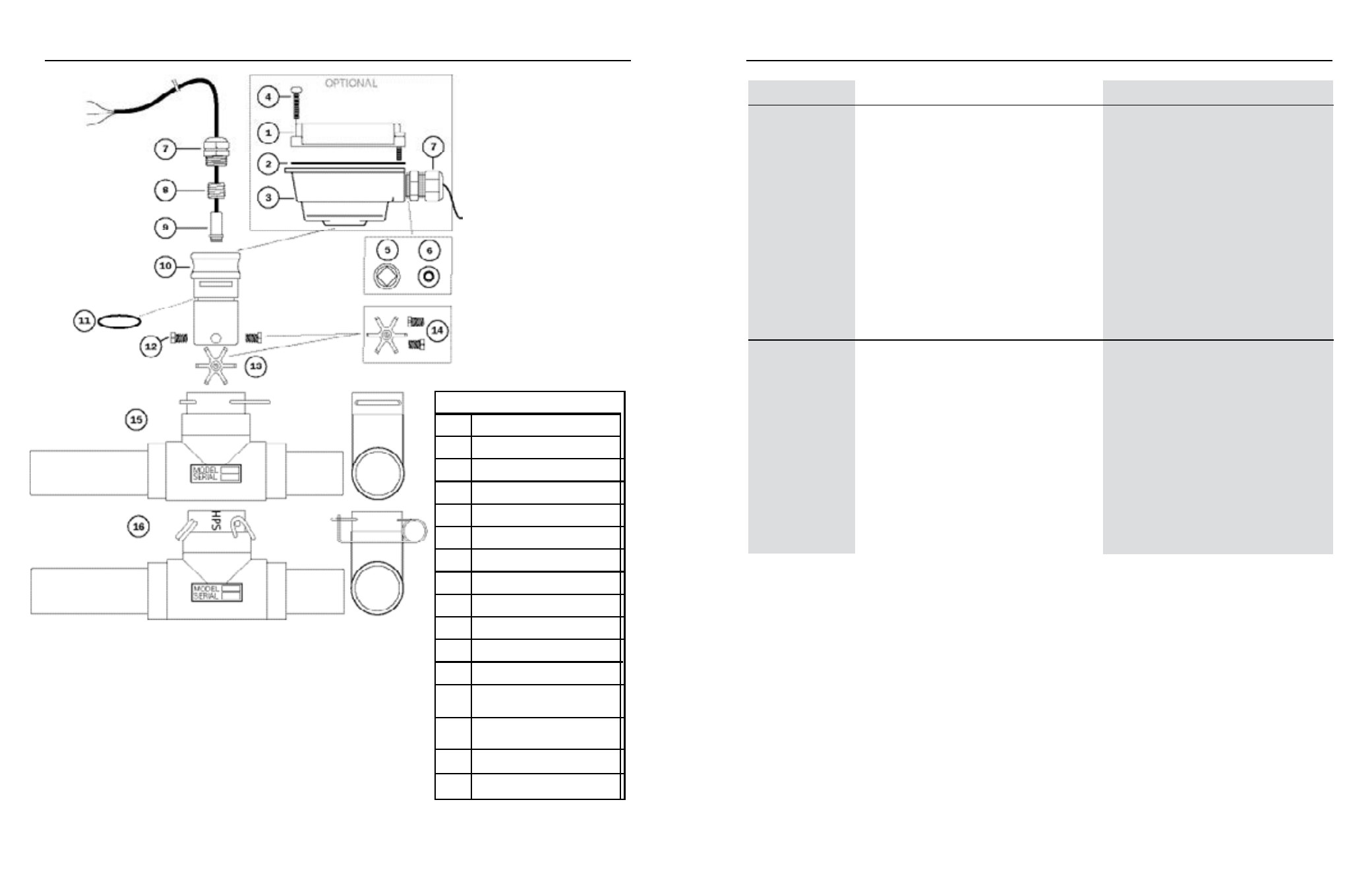

PaRtS eXPlOSiON

Upper Housing

Gasket

Lower Housing

Housing Screw Assembly

Plug, Steel

Plug, Plastic

Strain Relief

Sensor Retainer

Sensor, Low Power

Body

O-Ring, EPDM

Bearing Screws (2)

Rotor (Nickel/Carbide Shaft)

Rotor (Ceramic Shaft)

Rotor Repair Kit (Kynar/Carbide)

Rotor Repair Kit (Kynar/Ceramic)

Standard Fitting

High Pressure Fitting

SeRieS PDWS PaRtS liStiNG

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Page 10

Page 11