3 unpacking and inspecting the delivery, 4 material specifications of components, 5 suitable liquids (medium) – Dwyer MFS User Manual

Page 4: 6 installation of the flow sensor, 1 mechanical installation, Unpacking and inspecting the delivery, Material specifications of components, Suitable liquids (medium), Installation of the flow sensor, Mechanical installation

Unpacking and inspecting the delivery

3 Unpacking and inspecting the delivery

ª

Unpack your flow sensor MFS.

The MFS is delivered in special protective packaging. Keep this protective packaging for sending the instrument

for repairs to the manufacturer, or dispose the packaging under the official rules of the public waste disposal

system of your area.

ª

Inspect the delivery first.

Standard delivery MFS:

• flow

sensor

• operating

instructions

4 Material specifications of components

Prior to installation, ensure whether the wetted components are suitable for the medium to be measured!

Components Materials

Mediums contacting

Electrodes

Stainless steel 316 SS

Yes

Process connections

Stainless steel 316 SS

Yes

Pipe

PEEK Victrex 450GL30

Yes

Gasket EPDM

Yes

Housing

Aluminium pressure diecasted

No

5 Suitable liquids (medium)

Liquids with a minimum conductivity of 50 μS/cm are suitable as the medium. Always ensure whether the

material of the flow sensor is suitable for the medium to be measured.

6 Installation of the flow sensor

6.1 Mechanical installation

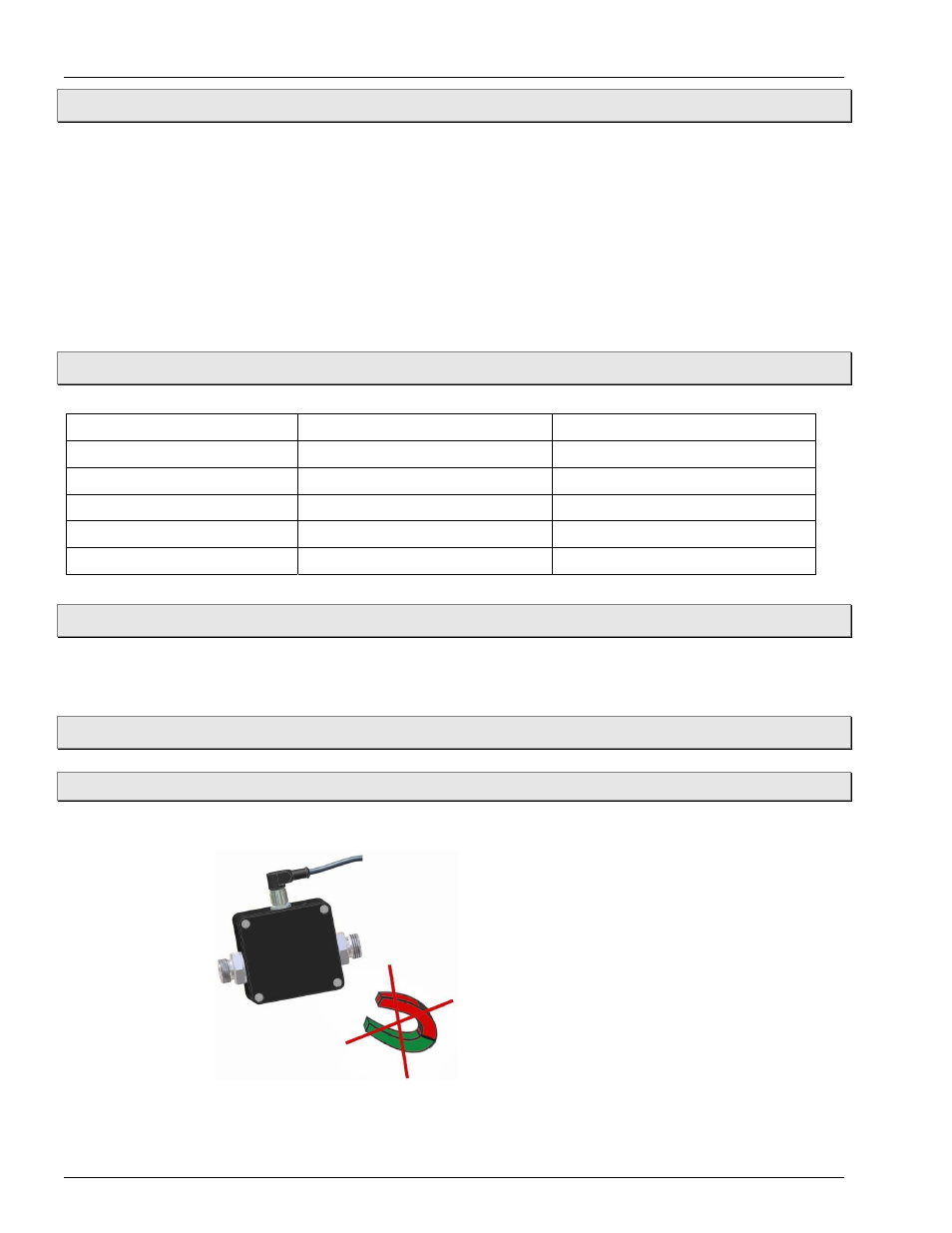

• Protect the flow sensor against external magnetic fields in the immediate vicinity, as these can impair device

functioning (see Fig. 2).

Fig. 2:

No external magnetic fields in the

immediate vicinity of the MFS

• The sensor can be installed at any position in the pipe system. Straight pipe sections are recommended

because the flow velocity may vary in bends (see Fig. 3).