Dwyer GFM2 User Manual

Page 13

9.3 Technical Assistance

Dwyer Instruments will provide technical assistance over the phone to qualified

repair personnel. Please have your Serial Number and Model Number ready

when you call.

10. CALIBRATION CONVERSIONS FROM REFERENCE GASES

The calibration conversion incorporates the K factor. The K factor is derived from

gas density and coefficient of specific heat. For diatomic gases:

Note in the above relationship that d and Cp are usually chosen at the same

conditions (standard, normal or other).

If the flow range of a Mass Flow Meter remains unchanged, a relative K factor is

used to relate the calibration of the actual gas to the reference gas.

For example, if we want to know the flow rate of oxygen and wish to calibrate

with nitrogen at 1000 SCCM, the flow rate of the oxygen is:

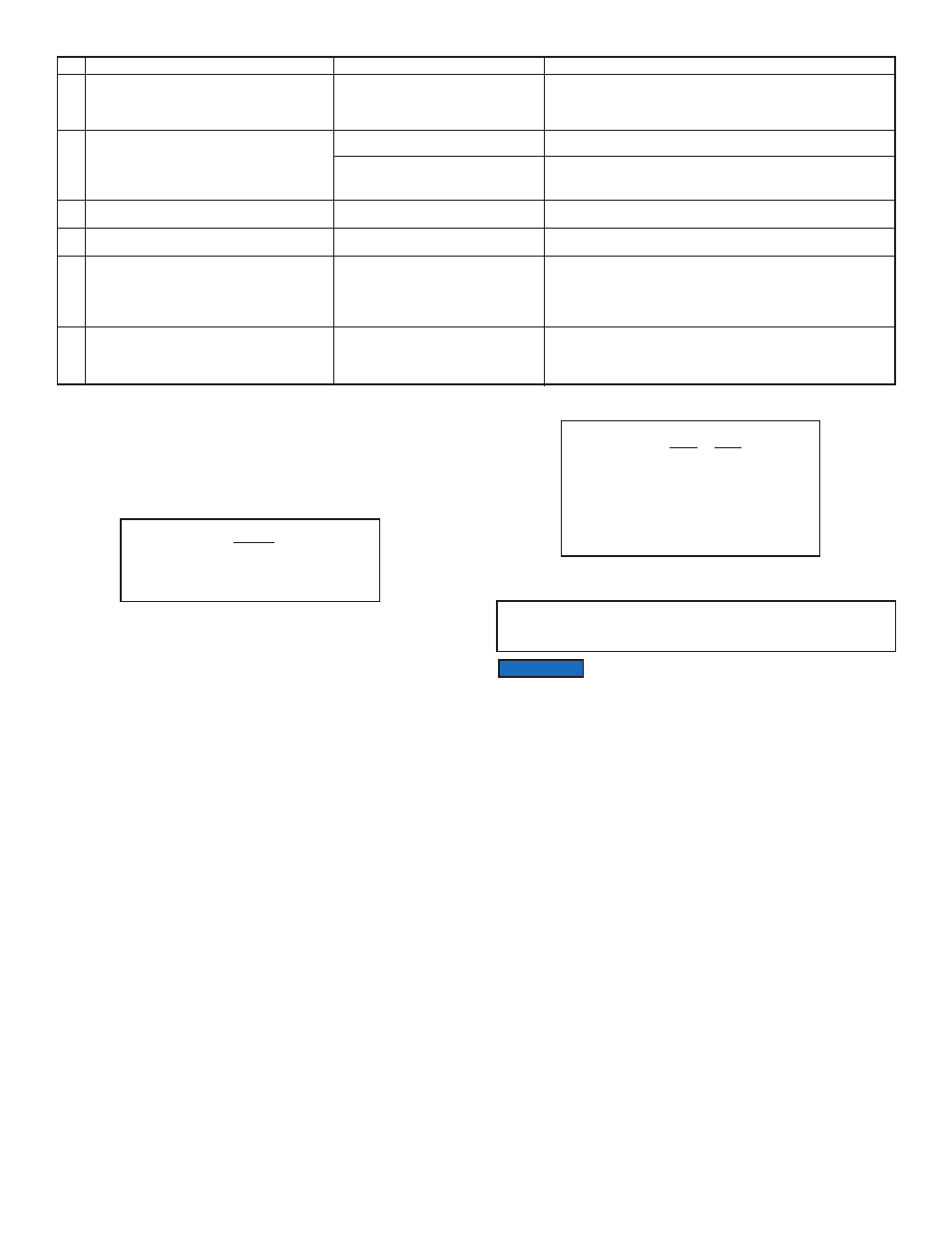

No.

9

10

11

12

13

14

Indication

Gas does not flow through the GFM2 with inlet

pressure applied to the inlet fitting. LCD display

reading and output voltage 0 to 5 VDC signal

show zero flow.

Gas flows through the GFM2, output voltage 0 to

5 VDC signal does not respond to flow (reading

near 1mV).

The Status LED indicator is rapidly flashing with

UMBER color on /off.

The Status LED indicator is rapidly flashing with

RED color on /off.

The Status LED indicator is rapidly flashing with

RED and UMBER colors.

The Status LED indicator is constantly on with

the RED light.

Likely Reason

Filter screen obstructed at inlet.

Direction of the gas flow is reversed.

GFM2 is connected in the installation

with back pressure conditions and gas

leak exist in the system.

Sensor temperature is too low.

Sensor temperature is too high.

MCU temperature is too high (overload).

Fatal Error (EEPROM or Auto Zero

error).

Solution

Flush clean or disassemble to remove impediments or replace the

filter screen (see section 6.2). NOTE: Calibration accuracy can be

affected.

Check the direction of gas flow as indicated by the arrow on the front

of the meter and make required reconnection in the installation.

Locate and correct gas leak in the system. If GFM2 has internal leak

return it to factory for repair.

Make sure the ambient and gas temperatures are within specified

range (above 5°C).

Make sure the ambient and gas temperatures are within specified

range (below 50°C).

Disconnect power from the GFM2. Make sure the ambient

temperature is within specified range (below 50°C). Let the device

cool down for at least 15 min. Apply power to the GFM2 and check

Status LED indication. If overload condition will be indicated again the

unit has to be returned to the factory for repair.

Cycle the power on the GFM2. If Status LED still constantly on with

RED light, wait 6 min. and start Auto Zero function (see 5.3.7 Zero

Calibration). If after Zero Calibration the Fatal Error condition will be

indicated again the unit has to be returned to the factory for repair.

1

d X Cp

where d = gas density (gram/liter)

Cp = coefficient of specific heat (cal/gram)

=

Kgas

Qa

Ka

Qr

Kr

where Qa = mass flow rate of an actual gas

(sccm)

Qr = mass flow rate of a reference gas

(sccm)

Ka = K factor of an actual gas

Kr = K factor of a reference gas

=

K

=

QO = Qa = Qr x K = 1000 X 0.9926 = 992.6 sccm

where K = relative K factor to reference gas (oxygen to nitrogen)

2

If particular K factor is activated via digital interface, the user

does not need to perform any conversion. All conversion

computations will be performed internally by MCU.

NOTICE

Page 13