Dwyer AFG User Manual

Page 2

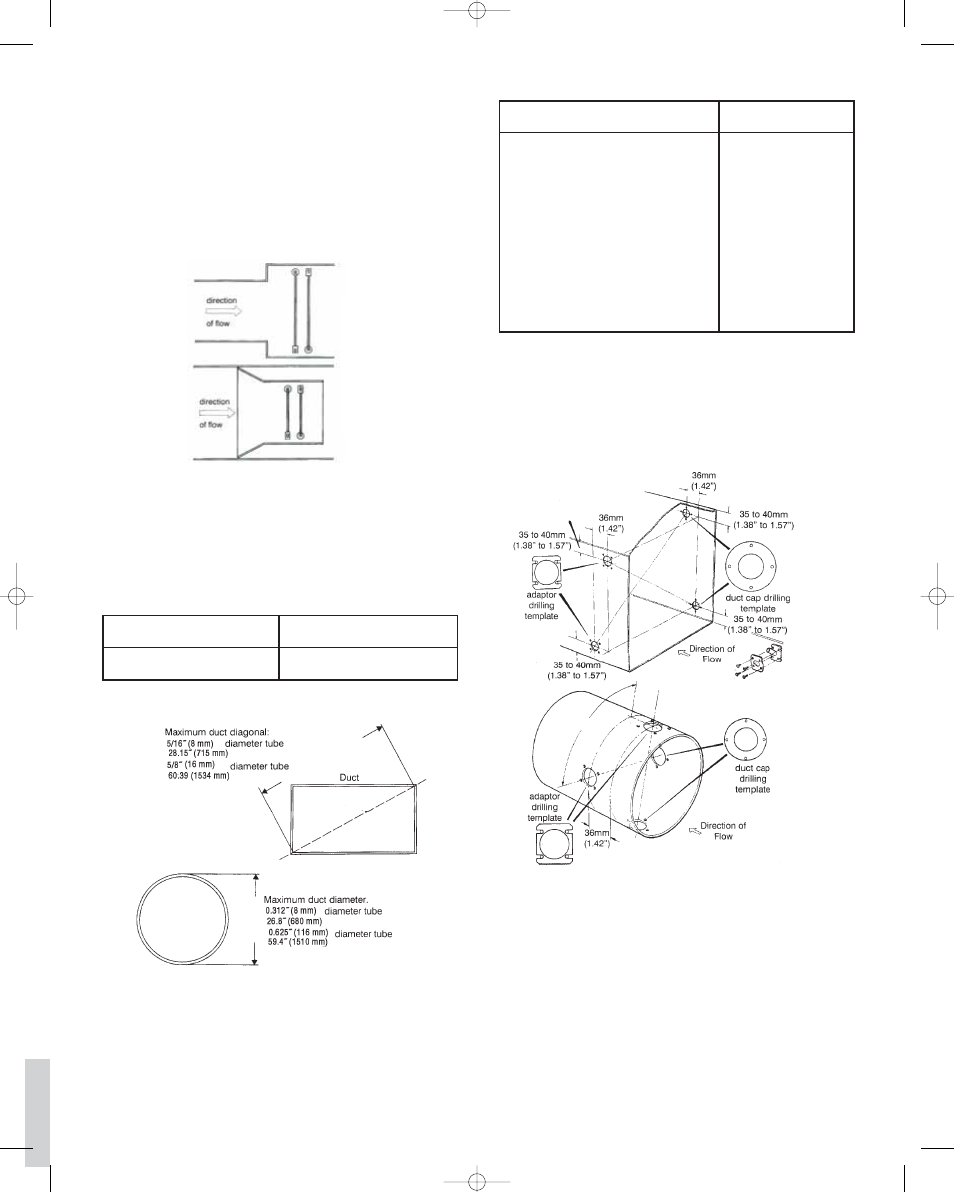

4. Avoid a sudden expansion immediately before an AFG Flow

Grid (See Fig. 2a).

5. A local contraction at the plane of the AFG Flow Grid is a use-

ful technique to increase pressure differential when velocities are

low (See Fig. 2b).

6. Where persistent swirl is expected it is advisable to install an

anti-swirl device at least 1D upstream from the AFG Flow Grid.

Note: For rectangular duct D = Width + Height of Duct/ 2

INSTALLATION

The AFG Flow Grids are supplied in kit form, and tube lengths are

cut to suit the required duct size by the customer.

The AFG Flow Grid is available in two tube diameters and lengths

(See Table 1).

Table 1: Dimensions

They may be used in square, rectangular or round ducts.

Unpack your AFG Flow Grid. The kit should contain the following

parts:

Table 2: Included Parts

Decide on the best location for your AFG Flow Grid.

The AFG Flow Grid is designed to fit into the shortest duct sides

of a rectangular duct or across a duct diameter. Mark out the duct

to the dimensions shown in Fig. 4 and 5. Attach the self-adhesive

templates supplied, and produce the holes to the sizes indicated

on the templates. DEBURR the 1.26˝ (32 mm) diameter holes.

Introduce tubes into the duct and secure at the adapter end using

the clamping plate and No. 6 self-tapping screws supplied (See

Fig. 6 and 7). Note position of tubes relative to the direction of flow

(See Fig. 7).

page 2

Tube Diameter “A”

5/16˝ (8 mm)

5/8˝ (16 mm)

Tube & Adapters

Supplied Length Size “B”

27˝ (688 mm)

59-4/5˝ (1518 mm)

Quantity

2

2

2

2

2

2

2

2

2

2

2

2

16

Description

Adapter & Pressure Tube

Adapter Plate

Duct Cap

Cap Plate

Adapter Drilling Template

Duct Cap Drilling Template

Diaphragm

Elbow

Tube Cap

Grommet

Cap Seal

Adapter Seal

Screws, Self Tapping No. 6 x 5/8˝

Fig. 2

a) Unacceptable

b) Acceptable

Fig. 3

Fig. 4

Fig. 5

AFG iom1 1/3/06 2:00 PM Page 2