Installation, Maintenance – Blue Angel Pumps CBP33 User Manual

Page 2

Flood

risk. If

flexible discharge hose is used, make

sure pump is secured in sump pit to

prevent movement. Failure to secure

pump could allow pump movement and

switch interference and prevent pump

from starting or stopping.

IMPORTANT: Make sure there is

adequate room for float switch to move

freely during operation.

7. Protect electrical cord from sharp

object, hot surfaces, oil and

chemicals. Avoid kinking the cord

and replace damaged cords

immediately.

8. A sump pit cover must be installed to

prevent debris from clogging or

damaging the pump.

Risk of electrical shock! This

pump is supplied with a

grounding conductor and

grounding type attachment plug. Use a

grounded receptacle to reduce the risk

of fatal electrical shock.

Never cut

off the round grounding prong.

Cutting the cord or plug will void the

warranty and make the pump

inoperable.

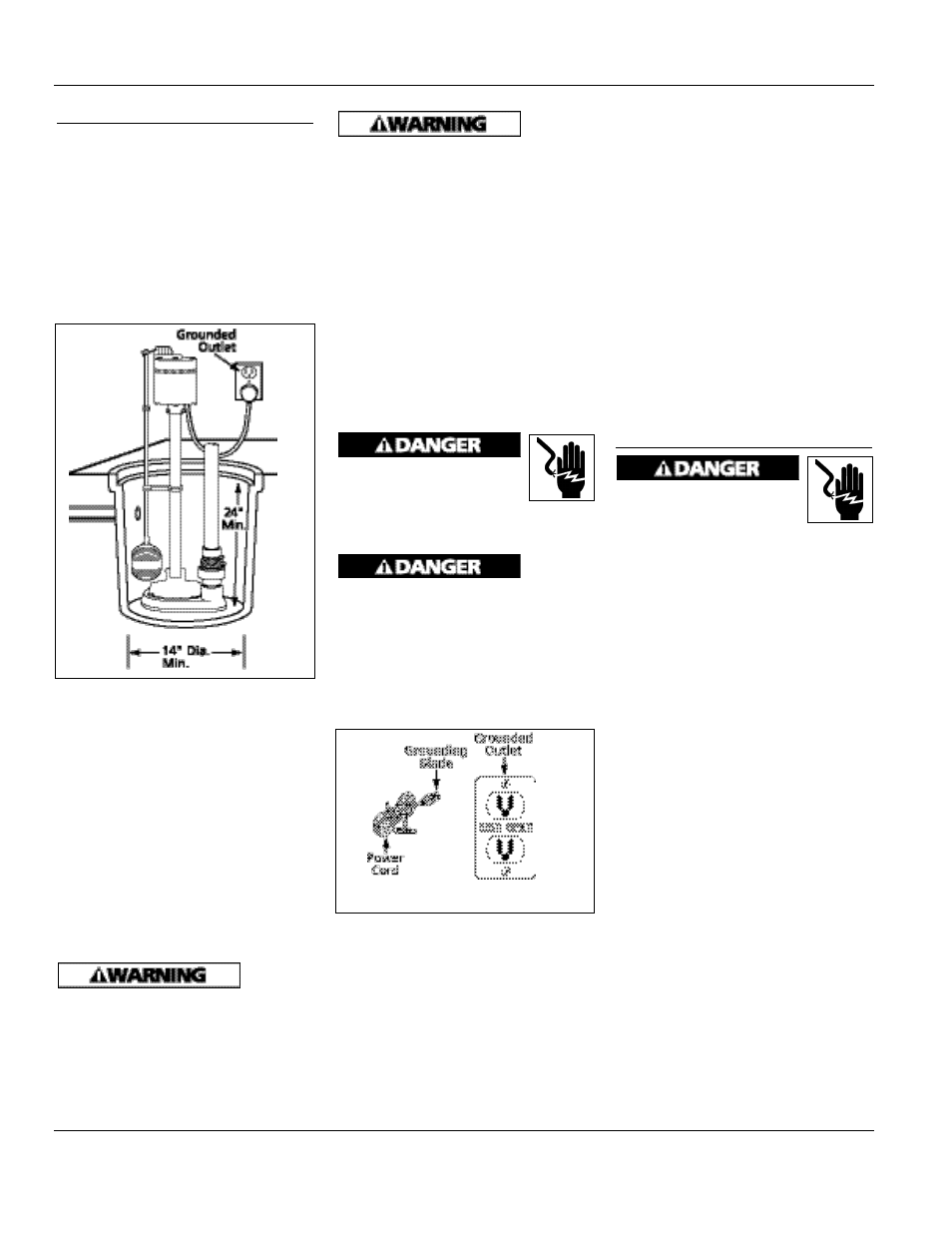

9. Insert the float switch cord plug

directly into a 120 volt outlet (See

Figure 3).

Installation

1. A ground fault circuit interrupter

(GFCI) is required.

2. This pump is for use on 120 Volt

(single phase), 60 hz, 15 amp service

and is equipped with a 3 conductor

cord and a 3 prong grounding plug.

3. Install pump in an indoor sump pit

with minimum size as shown (See

Figure 2). Construct sump pit of tile,

concrete, steel or plastic.

4. Locate unit on a solid, level

foundation. Do not place pump

directly on clay, earth, gravel or

sandy surface. These surfaces contain

small stones, gravel, sand, etc. that

may clog or damage the pump and

cause pump failure (See Figure 2).

5. (Optional) Thread check valve (not

included) into pump body carefully

to avoid stripping or cross threading.

Do not use pipe joint sealant.

6. Connect 1-1/4” rigid pipe to rubber

boot on check valve. Reverse boot

for 1-1/2” diameter pipe. Tighten

hose clamps.

Support

pump and

piping when assembling and after

installation. Failure to do so could

cause piping to break, pump to fail,

etc. which could result in property

damage and/or personal injury.

2

Operating Instructions and Parts Manual

ADJUST AND TEST

1. Fill sump with water.

2. Adjust rubber grommet into a

permanent position on float rod so

that the pump switches on with

approximately 14” of water in the

sump.

3. While the pump is draining the pit,

verify that the discharge piping is

carrying the water to a point

several feet away from the

foundation.

4. If the pump discharge line is

exposed to freezing temperature,

the exposed line must be pitched to

drain. Trapped water will freeze

and damage the pump.

Maintenance

Always disconnect the

electrical supply before

attempting to install, service,

relocate or perform any maintenance.

If the power source is out of sight, lock

and tag in the open (off) position to

prevent unexpected power application.

Failure to do so could result in fatal

electrical shock. Only qualified

electricians should repair this unit.

Improper repair could result in fatal

electrical shock.

1. Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required, see

troubleshooting chart.

2. Keep pump inlet clean and free of all

foreign objects and inspect annually.

A clogged inlet will damage pump.

3. Check pump monthly for proper

operation.

Note: Pump is equipped with an

automatic reset thermal protector.

Figure 3

Figure 2

www.blueangelpumps.com

2