Iii. installation – Badger Meter CV Series User Manual

Page 4

Page 4

Form #4-20-23 11/10

III. Installation

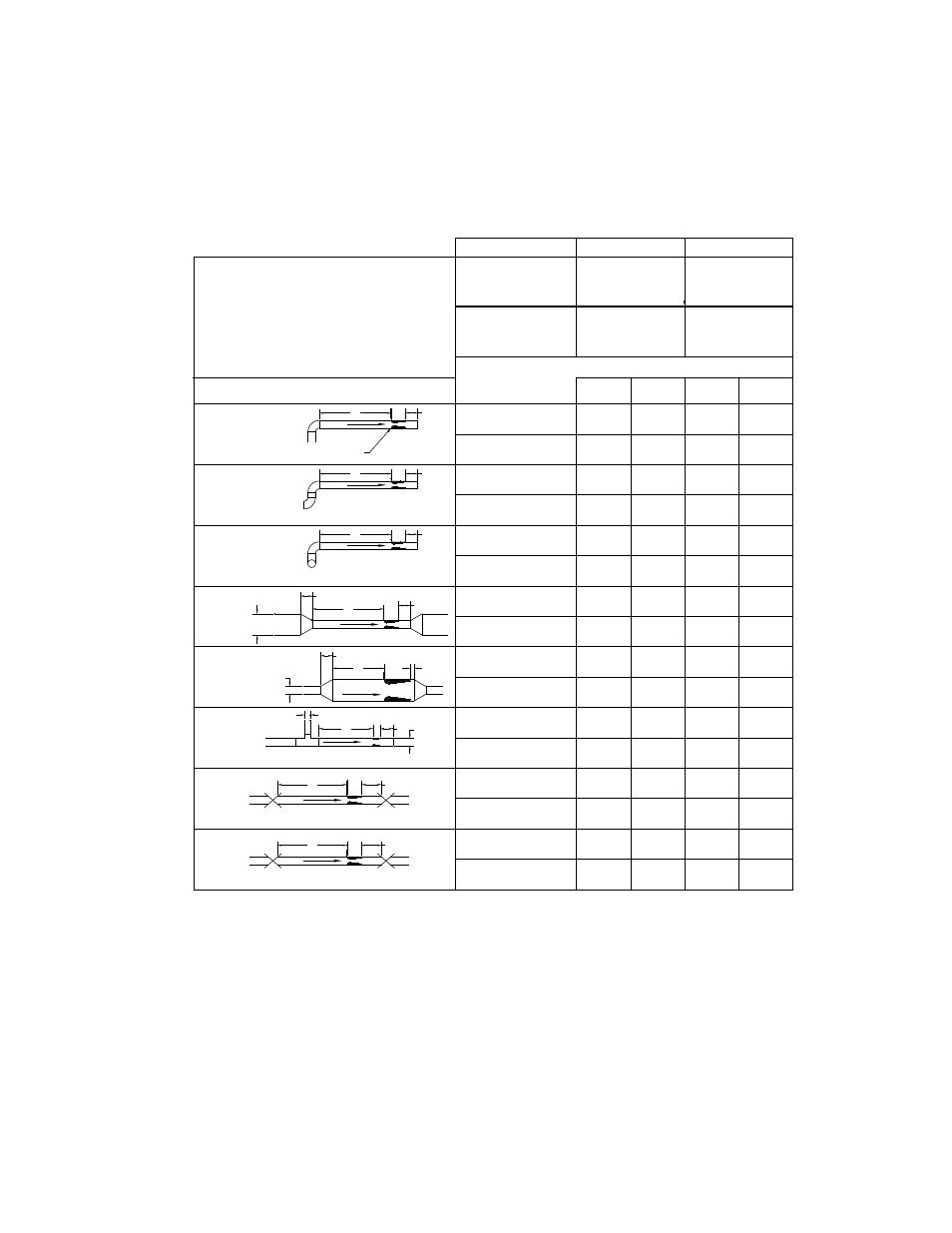

Straight Pipe Run Requirements - SSL, SSM, LPL, VISSL, VISSM, VILPL

As with most fl ow elements, proper operation and performance is dependent on the required

lengths of unrestricted upstream and downstream piping. The recommended minimum length

of the upstream side of the Venturi fl ow element depends on the type of fi tting at the start of the

straight run and the pipe confi guration. A fully developed symmetrical fl ow profi le is achieved with

the minimum upstream and downstream lengths as shown in Figure 1.

FIGURE 1

Venturi Pipe Diameter Recommendations

SSL, SSM, LPL, VISSL, VISSM and VILPL Models

NOTES:

1. For upstream and downstream lengths equal to one half the values shown, add 2 percent to the accuracy

value.

2. Any

fl ow conditioner shall be installed in the straight length between the primary element and the

upstream distance, or the fi tting closest to the element. The straight lengths between fi tting and

conditioner shall be at least 5D and the length between conditioner and Venturi meter shall be at least 8D.

3. For other fi ttings, confi gurations, consult Preso.

4. Reference - ISO-5167, "Flow Measurement Engineering Handbook", R.W. Miller.

Globe / Gate valve fully opened

Globe / Gate valve partially opened

Tee connection with different diameters

Expander

Reducer

Two elbows in different planes

Two elbows in the same plane

Single elbow

INSTALLATION DISTURBANCE

A

B

1.5 to 3D

≤ 2D

A

B

Venturi

A

B

A

B

A

B

A

A

A

A

A

A

B

B

B

B

B

B

B

A

4

4

4

5

2

2

2

2

8

8

9

10

3

3

3

3

15

15

15

4

4

4

4

20

7

6

6

6

2

2

2

2

10

8

8

8

3

3

3

3

10

8

8

8

3

3

3

3

3

6

6

6

3

3

3

3

18

14

12

12

3

3

3

3

Minimum Recommended Pipe Diameters

–1

–10

–2

–20

–3

–38

–4

–65

MODEL

THROAT SIZE

BETA RATIO

0.35

0.49

0.63

0.75

0.35

0.49

0.62

0.81

–1

–2

–3

–4

–10

–20

–38

–65

SSL / VISSL – Classical

SSM / VISSM – Nozzle

LPL / VILPL – Low-Loss

≥ 0.5D

1D to 2D

B

A

A

B

D

d or D

A

B

A

B