Installation instructions, single support – Badger Meter AR - Regular (2 to 72")" User Manual

Page 5

INSTALLATION INSTRUCTIONS, SINGLE SUPPORT

1 . Choose the proper location to install the AR Ellipse using AGA/ASME standards (or equivalent) . See

"Preso Ellipse Location

Instructions" on page 7

.

2 . Grind the surface of the pipe where the AR Ellipse is to be inserted to provide a clean area for welding .

3 . Weld the supplied thread-o-let to the pipe using standard codes for your application (1/16" weld gap recommended) . Take

care to protect the threads during the welding process .

4 . Drill a hole through the pipe wall according to

.

Model / Sensor

Weld Connector

Drill Bit

AR0 (1/2")

1/2"

5/8"

AR (7/8")

1"

1-1/8"

AR1 (1-1/4")

1-1/4"

1-3/8"

Table 2: Single support drill bit size

5 . Deburr the hole just drilled, especially on the inside of the pipe .

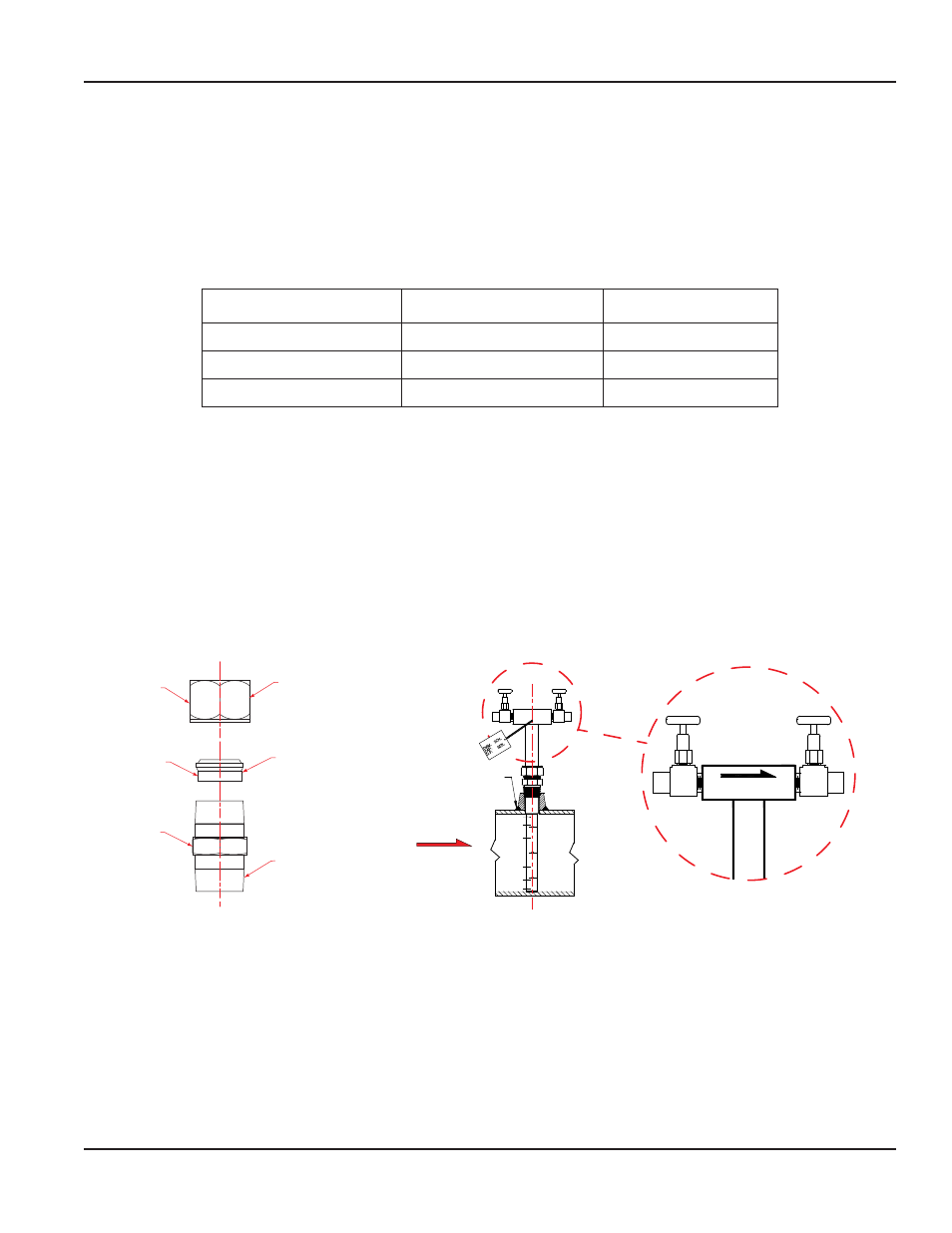

6 . Assemble the supplied compression fitting as diagrammed in

. Thread the assembled compression fitting into the

thread-o-let manually . With a wrench, tighten the body of the fitting a further 1-1/4 turns taking care not to tighten the

compression nut .

7 . Install the instrument valves (optional) at the AR Ellipse head connections . Ensure that the valves are FULLY CLOSED to

prevent them from leaking during startup .

8 . Insert the AR Ellipse through the compression fitting . Carefully push the sensor by hand further into the pipe until it

reaches the opposite wall .

9 . While holding the AR Ellipse in its fully inserted position, align the arrow located on the sensor head with the direction of

flow . See

Nut

Insert

Body

Thread nut loosely

onto body of the

compression fitting

Install insert

as shown

Threaded portion

to be installed

into weld fitting

on pipe

Field Weld

FLOW

FLOW

H

L

H

L

Nut

Insert

Body

Thread nut loosely

onto body of the

compression fitting

Install insert

as shown

Threaded portion

to be installed

into weld fitting

on pipe

Field Weld

FLOW

FLOW

H

L

H

L

Figure 5: Compression fitting

Figure 6: Sensor alignment

10 . Thoroughly tighten the compression nut in order to prevent leakage . After tightening the compression nut manually, turn

it a further 1-1/4 turns with a wrench .

User Manual

Page 5

April 2014