Introduction, Specifications – Badger Meter AR - Regular (2 to 72")" User Manual

Page 3

INTRODUCTION

The Preso elliptical design outperforms and provides greater accuracy than

traditional differential pressure flow measurement devices . This differential

pressure flow meter is designed with a series of ports facing the upstream

velocity pressures, as well as flow sensing ports strategically located ahead of

the trailing edge flow separation .

The multi-ported, self-averaging flow element consists of an elliptical shape

with two independent flow sensing chambers . The impact velocity sensing

holes (high pressure) are located along the leading edge and the true static

sensing holes (low pressure) are on the exterior probe side . Model AR comes

with instrument shutoff valves with provisions to accept a transmitter or direct

indicating meter .

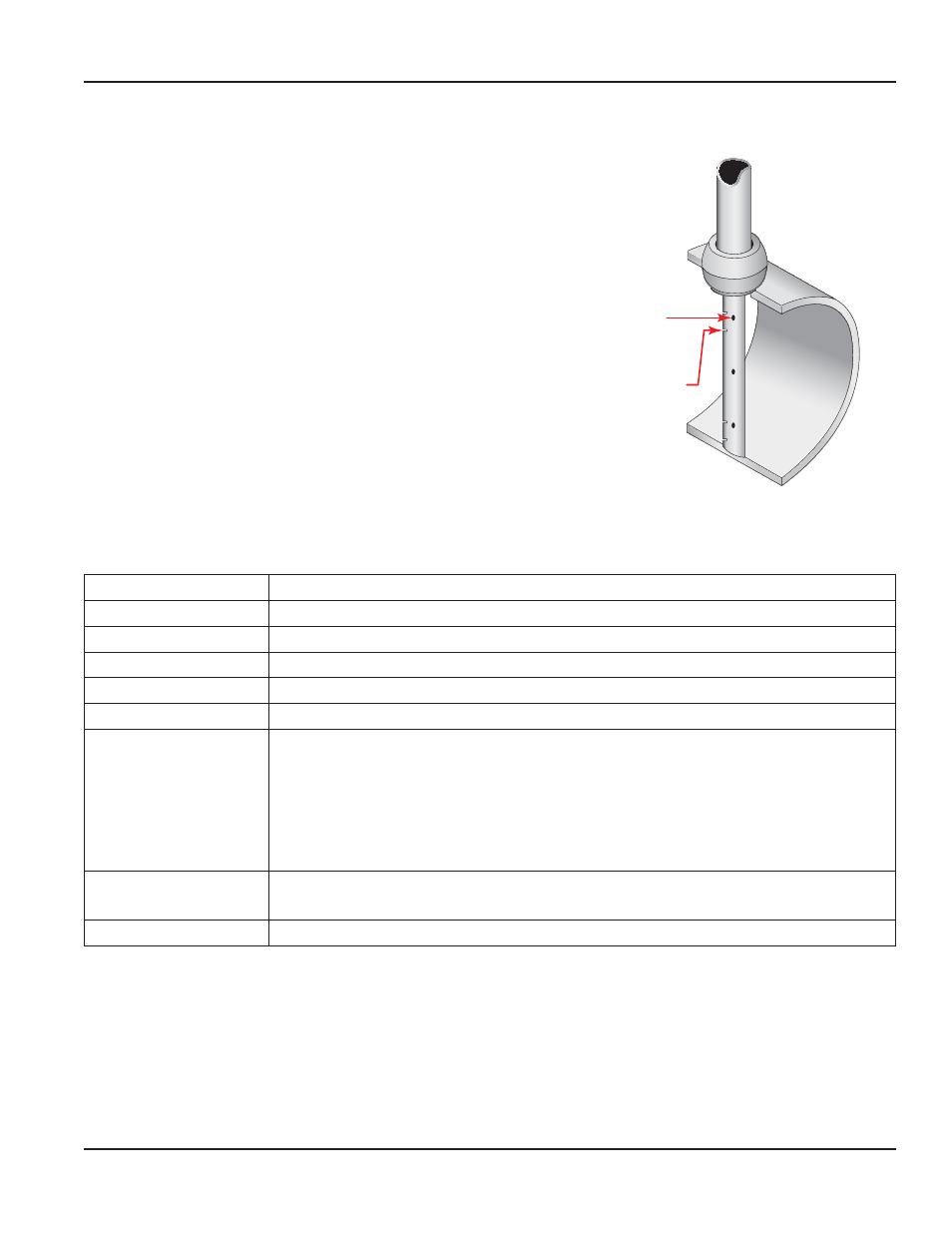

True static

sensing holes

Impact velocity

sensing holes

Figure 1: AR pressure sensing holes

SPECIFICATIONS

Applications

Liquids and gases

Pipe Sizes

2…72 inches (50…1820 mm)

Pressure

800 psi (5515 kPa) maximum

Temperature

800° F (426° C) maximum

Accuracy

±0 .75% of reading

Turndown Ratio

17:1 with no vacuum effect

Standard Components

T-type head, 316 SS 1/4" or 1/2" FNPT connection

CS compression fitting with SS ferrule

CS 3000 lb weld fitting, ASTM A105

316/316L SS Ellipse sensor

Instrument valves (2 per sensor), 1/4", CS

316 SS ID tag with wire

Reynolds Number

Greater than 75,000 maintains most accurate flow measurements

Less than 75,000 consult factory for estimated results

Resonance

If greater than 0 .8, use double support

Table 1: Specifications

User Manual

Page 3

April 2014